Table of Contents

Product Detail

Spray drying is a fascinating and versatile technique used extensively across various industries to transform liquid substances into dry powders. This technique involves atomizing a liquid feed into a spray of droplets and rapidly drying them using a hot air stream. It is widely favored for its ability to produce uniform and fine particles while preserving the chemical properties of the original material. In this expanded article, we’ll delve deeper into the benefits and applications of chemical spray dryers, exploring their working principles, types, and innovations.

What is a Spray Dryer?

A spray dryer is a sophisticated device used to convert liquid substances into dry powders by rapidly drying them with a hot gas. The process kicks off with the atomization of the liquid feed into tiny droplets. These droplets are then introduced into a drying chamber, where they come into contact with hot air. This interaction causes the moisture in the droplets to evaporate quickly, leaving behind dry particles that are subsequently collected and stored. The rapidity of this process is crucial, as it ensures that the core qualities of the original liquid, such as its flavor, nutritional value, or chemical properties, are retained.

The Working Principle

The working principle of a spray dryer revolves around three main stages: atomization, drying, and collection. During atomization, the liquid feed is transformed into a fine mist using an atomizer, which can be a rotary disk, nozzle, or pressure nozzle. The choice of atomizer depends on the desired particle size and the properties of the liquid being dried. Once atomized, the fine droplets are introduced into the drying chamber, where they are met with a stream of hot air. This hot air rapidly evaporates the liquid, leaving behind solid particles. Finally, these dry particles are collected using cyclone separators or bag filters, ensuring that the final product is free from any residual moisture or impurities.

Types of Spray Dryers

There are several types of spray dryers, each designed to cater to specific applications and material characteristics. These variations allow for greater versatility in the spray drying process, accommodating different production scales and material sensitivities.

Conventional Spray Dryer

The conventional spray dryer is the most widely used type, employed in drying a diverse range of products, from food items to chemicals. It comprises a drying chamber, atomizer, and air heater. The conventional design is known for its efficiency and its capacity to produce particles with consistent sizes. It is particularly favored in situations where uniform particle size is critical, such as in the production of certain food additives or chemical compounds.

Pulse Jet Spray Dryer

Pulse-jet spray dryers are specifically designed to handle heat-sensitive materials. They utilize short bursts of hot air to dry the droplets, thereby minimizing the time the material is exposed to high temperatures. This feature makes them ideal for drying pharmaceuticals and biochemicals, where maintaining the integrity of the active ingredients is paramount. The ability to control the exposure time to heat allows for the preservation of delicate compounds that might otherwise degrade under prolonged heat exposure.

Vacuum Spray Dryer

Vacuum spray dryers operate under reduced pressure, which allows for lower drying temperatures. This makes them particularly suitable for drying materials that are sensitive to heat and oxygen. By reducing the boiling point of water, vacuum spray dryers can gently dry products without compromising their quality. This approach is beneficial for substances like probiotics or certain vitamins that are prone to degradation when exposed to high temperatures or oxygen.

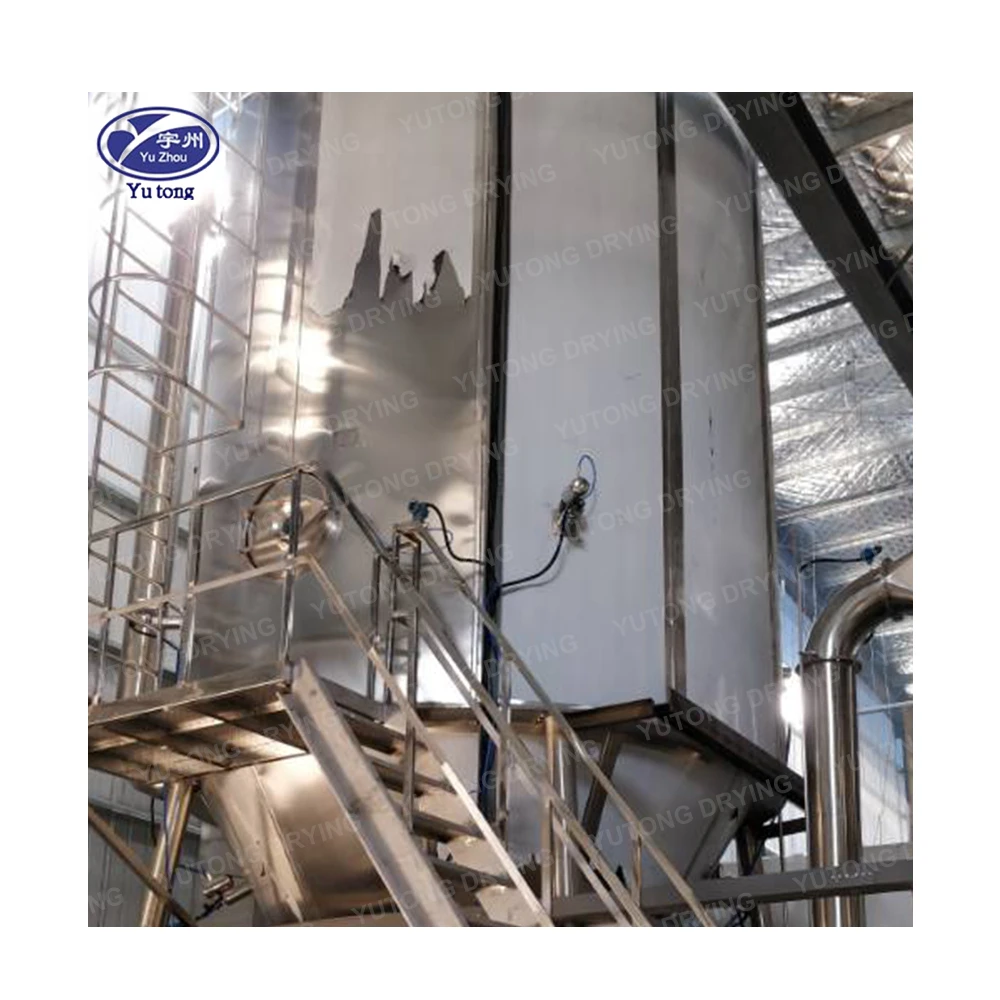

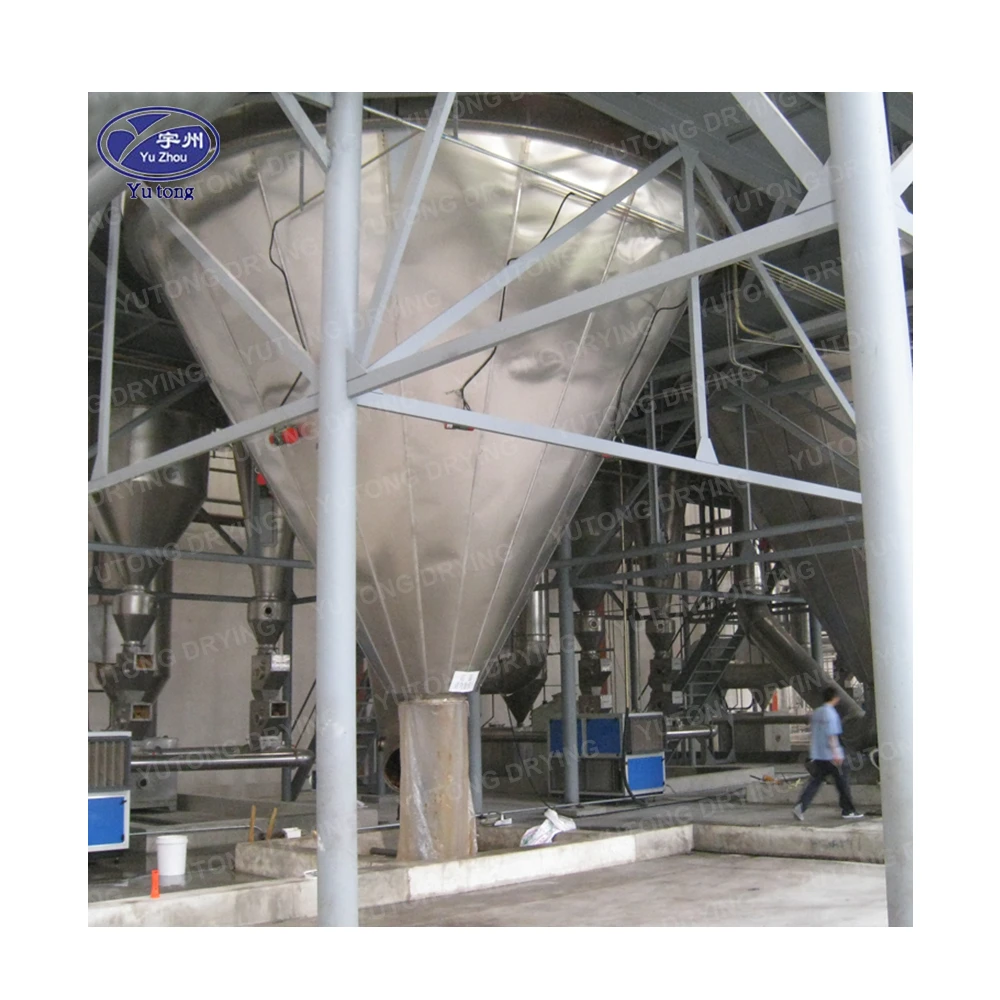

Tall Form Spray Dryer

Tall-form spray dryers, such as those by Dedert, are engineered for large-scale production. They feature a tall cylindrical design that allows for a longer residence time, ensuring thorough drying of the material. This design is particularly advantageous for processes that require extended drying times to achieve the desired moisture content. The tall form design also facilitates better particle separation and collection, improving the overall efficiency of the drying process.

Benefits of Using Spray Dryers

Spray dryers offer several advantages, making them a preferred choice in a variety of industries. Their ability to handle different materials and produce consistent results is just the tip of the iceberg.

Consistent Particle Size

One of the primary benefits of spray drying is its ability to produce particles with a consistent size and shape. This uniformity is crucial in industries like pharmaceuticals, where the size of the particles can significantly impact the efficacy and safety of drugs. Consistent particle size also plays a vital role in ensuring that the final product dissolves or disperses uniformly, which is essential for applications such as instant beverages or powdered detergents.

Preservation of Chemical Properties

Spray dryers are meticulously designed to minimize exposure to high temperatures, thereby preserving the chemical and physical properties of the original material. This is particularly important for heat-sensitive substances like enzymes and vitamins, which can lose their effectiveness if exposed to excessive heat. By maintaining the integrity of these compounds, spray drying ensures that the final product retains its intended functionality and benefits.

High Efficiency and Speed

The spray drying process is exceptionally fast, allowing for high throughput and efficiency. This speed is a significant advantage in large-scale production scenarios where time is of the essence. The rapid drying process not only boosts productivity but also reduces the risk of microbial contamination, which can occur in slower drying methods. The efficiency of spray drying makes it an ideal choice for industries that demand quick turnaround times without compromising quality.

Versatility

Spray dryers are incredibly versatile and capable of handling a wide range of materials, from slurries to solutions. They find applications in the food industry for products like milk powder and coffee, in the chemical industry for catalysts and pigments, and in the pharmaceutical industry for active ingredients. This versatility is one of the key reasons why spray drying is a favored technique across different sectors. Whether dealing with a simple aqueous solution or a complex slurry, spray dryers can be adapted to meet specific processing needs.

Applications of Spray Dryers

Due to their versatility and efficiency, spray dryers are employed in numerous industries. Their ability to produce high-quality powders makes them indispensable in various applications.

Food Industry

In the food industry, spray dryers are used to produce powdered products like milk, coffee, and spices. The process ensures that the nutritional value and flavor of the original product are retained. By controlling the drying conditions, manufacturers can produce powders with specific moisture contents and particle sizes, which are crucial for maintaining the quality and shelf life of food products. Additionally, spray drying allows for the production of instant food products that dissolve quickly in water, catering to the demands of modern consumers for convenience and speed.

Pharmaceutical Industry

Pharmaceutical companies rely on spray dryers to produce drugs in powder form. The ability to control particle size and moisture content is crucial for ensuring the efficacy and stability of the final product. Spray drying allows for the production of powders that are easily processed into tablets or capsules, facilitating precise dosage and administration. Furthermore, the process can be used to enhance the solubility and bioavailability of certain drugs, improving their absorption and effectiveness in the body.

Chemical Industry

In the chemical industry, spray dryers are used to produce catalysts, pigments, and other chemical powders. The process allows for precise control over the final product’s properties, such as particle size, shape, and moisture content. This control is essential for ensuring that the chemical powders meet the specific requirements of their intended applications. Whether used as catalysts in chemical reactions or as pigments in paints and coatings, the quality and consistency of the powders produced by spray drying are critical to their performance.

Challenges and Disadvantages

Despite their numerous benefits, spray dryers do present some challenges and disadvantages that need to be considered.

High Energy Consumption

Spray drying is an energy-intensive process, requiring significant amounts of heat to evaporate the liquid. This can result in high operational costs, particularly in large-scale production settings. Energy consumption is a critical factor in the overall cost-effectiveness of the spray drying process, and it necessitates careful consideration of energy sources and efficiency measures to minimize costs.

Equipment Cost

The initial cost of purchasing and setting up a spray dryer can be high. However, this is often offset by the efficiency and productivity gains achieved through the process. Investing in a high-quality spray dryer can lead to long-term savings in operational costs and improved product quality, making it a worthwhile investment for many industries.

Maintenance Requirements

Spray dryers require regular maintenance to ensure optimal performance. This includes cleaning the atomizer and drying chamber to prevent blockages and ensure consistent operation. Regular maintenance is essential for preventing equipment malfunctions and ensuring that the spray dryer operates at peak efficiency. While maintenance can be time-consuming, it is a necessary aspect of ensuring the longevity and reliability of the equipment.

Innovations in Spray Drying

Recent advancements in spray drying technology have addressed some of the challenges associated with the process, making it more efficient and environmentally friendly.

Energy Recovery Systems

Modern spray dryers are equipped with energy recovery systems that capture and reuse heat from the drying process, reducing overall energy consumption. These systems enhance the energy efficiency of spray drying, lowering operational costs and minimizing the environmental impact. By recapturing and reusing heat, manufacturers can significantly reduce their energy usage, contributing to sustainability efforts.

Improved Atomization Techniques

Advancements in atomization technology have led to more efficient and precise droplet formation, resulting in better control over particle size and distribution. These improvements enhance the quality and consistency of the final product, allowing for more tailored applications. By optimizing atomization, manufacturers can achieve greater uniformity in particle size, which is essential for maintaining product quality and performance.

Automation and Control

New spray dryers feature advanced automation and control systems that monitor and adjust the drying process in real time, ensuring consistent product quality. These systems allow for greater precision in controlling drying parameters, such as temperature and airflow, enhancing the efficiency and reliability of the process. Automation also reduces the need for manual intervention, minimizing the risk of human error and improving overall operational efficiency.

Conclusion

Spray dryers are a vital tool in many industries, offering a fast and efficient way to transform liquids into dry powders. Their ability to produce uniform particles while preserving the chemical properties of the original material makes them indispensable in sectors like food, pharmaceuticals, and chemicals. As technology continues to advance, spray dryers will become even more efficient and versatile, opening up new possibilities for their use.

For anyone considering investing in a spray dryer, understanding the specific requirements and benefits of different types is crucial. Whether you’re a small-scale lab or a large-scale manufacturer, there’s a spray dryer solution to meet your needs. By staying informed about the latest advancements and innovations in spray drying technology, businesses can optimize their processes and remain competitive in an ever-evolving market.

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food & Beverage Shops