Project Overview:

Sucralose (TGS) is a high-intensity sweetener originally developed in 1976 through a collaboration between Tate & Lyle and the University of London. Patented as a novel non-caloric sweetener, it is derived directly from sugar and marketed under the trade name Splenda. With a sweetness level approximately 600 times that of sucrose, sucralose is notable for its clean, sugar-like taste and excellent safety profile. It is widely recognized as one of the most advanced and functional sweeteners available today.

Material Description:

Sucralose, also known as TGS, is a high-purity sweetener synthesized from sucrose. Approved for food applications across various countries, including China, it retains a clean and natural sweetness similar to sucrose, without any caloric contribution. Sucralose is highly soluble in water and exhibits exceptional thermal and chemical stability, making it suitable for diverse processing conditions. It is commonly used in beverages, sauces, fermented foods, bakery products, ice creams, and more.

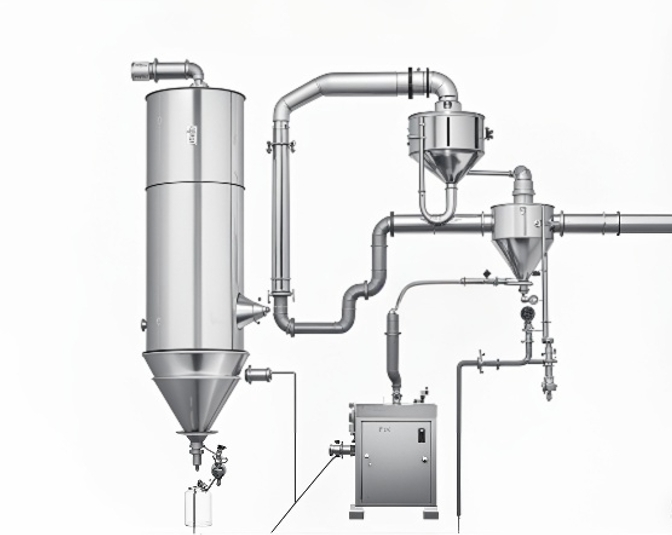

Working Principle:

Clean, heated air is introduced into the drying chamber from the bottom via an induced draft fan. This air passes through a perforated plate, fluidizing the material inside the chamber. Under negative pressure conditions, moisture is quickly evaporated and carried away by the airflow, enabling rapid and uniform drying.

Key Features:

-

Circular fluidized bed structure prevents material dead zones.

-

Hopper equipped with stirring mechanism to eliminate clumping and ensure even drying.

-

Optional tilting discharge system for easy and complete material removal.

-

Negative pressure operation with filtered airflow ensures cleanliness and containment.

-

Efficient drying with uniform temperature distribution; typical drying cycle lasts 20–30 minutes depending on material properties.

Suitable Materials:

-

Granules formed by screw extrusion, rolling, or high-speed mixing.

-

Moist granules and powders from pharmaceutical, food, chemical, and feed industries.

-

Larger or cohesive granules with slight stickiness.

-

Materials that undergo significant volume change during drying, such as konjac.