Table of Contents

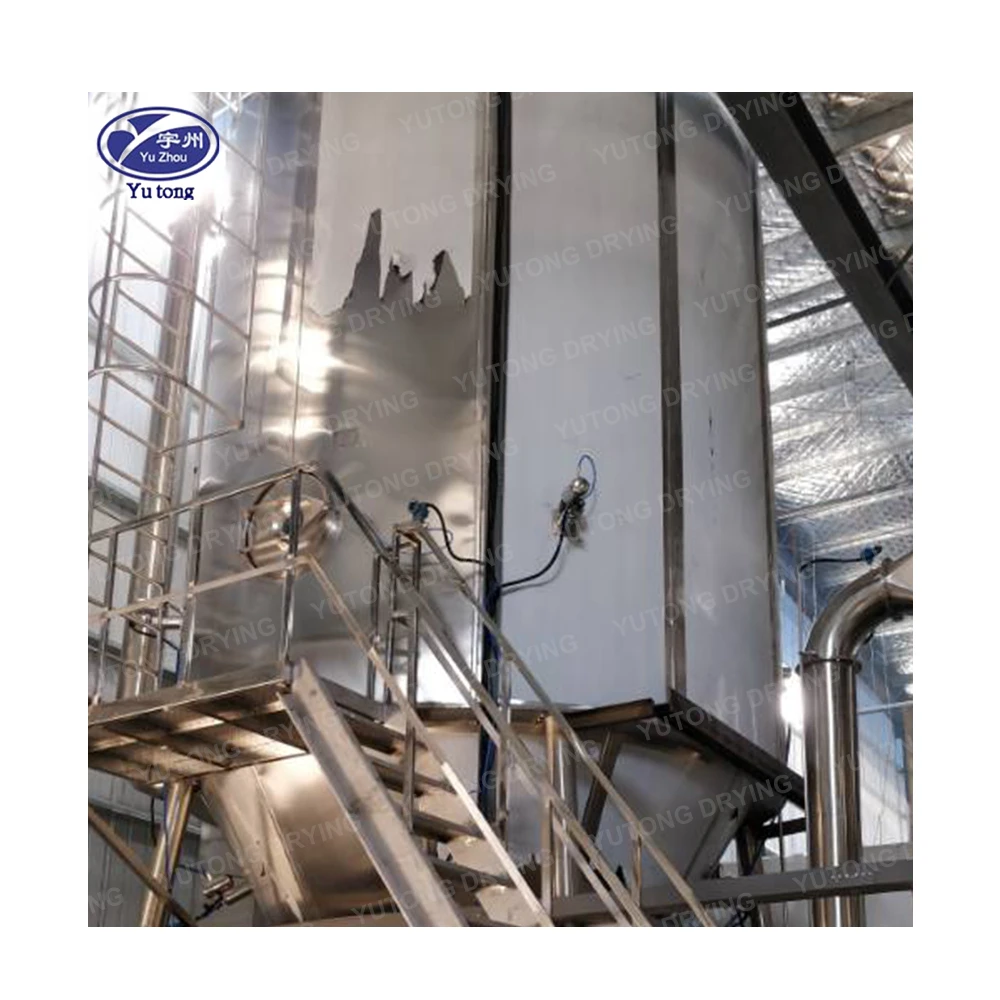

Product Detail

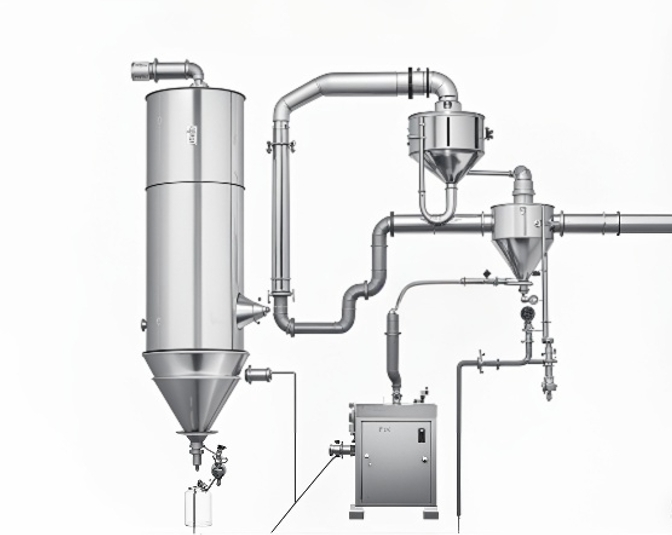

1. Industry-Leading Spray Drying Technology

Our Damrow spray dryers (and compatible DeLaval/Filtermat systems) deliver:

✔ High-yield powder production – Minimal thermal degradation

✔ Precise particle size control – Adjustable nozzle/atomizer settings

✔ Energy-saving designs – Heat recovery reduces operating costs

2. Key Applications

- Dairy Industry: Milk powder, whey protein, casein

- Food Processing: Egg powder, coffee, starch, plant proteins

- Pharmaceuticals: Probiotics, enzyme stabilization

3. Technology Comparison

| Model | Damrow | DeLaval | Filtermat |

|---|---|---|---|

| Best For | Large-scale dairy | Medium-capacity foods | Agglomerated powders |

| Atomization | Nozzle-based | Centrifugal | Belt drying + spray |

| Unique Feature | High thermal efficiency | Compact footprint | Low-temperature drying |

4. Customizable Options

- Sanitary Designs: 304/316L stainless steel, CIP cleaning

- Explosion Protection: ATEX compliance for flammable powders

- Automation: PLC control with moisture feedback loops

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

solid content of material liquid( %)

|

18-30

|

|||||||

|

moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam pius electricity

|

|||||||

|

Collecting method of product and its efficiency

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food & Beverage Shops