Spray drying is a widely used technique in various industries, from food processing to pharmaceuticals. It involves transforming a liquid into a powder by rapidly drying it with a hot gas. While the process might seem straightforward, several factors can significantly influence the efficiency and performance of a spray dryer. Understanding these factors is crucial for optimizing the spray drying process and achieving the desired product quality. In this article, we’ll delve into the key factors affecting spray dryer performance and offer insights into how you can enhance efficiency.

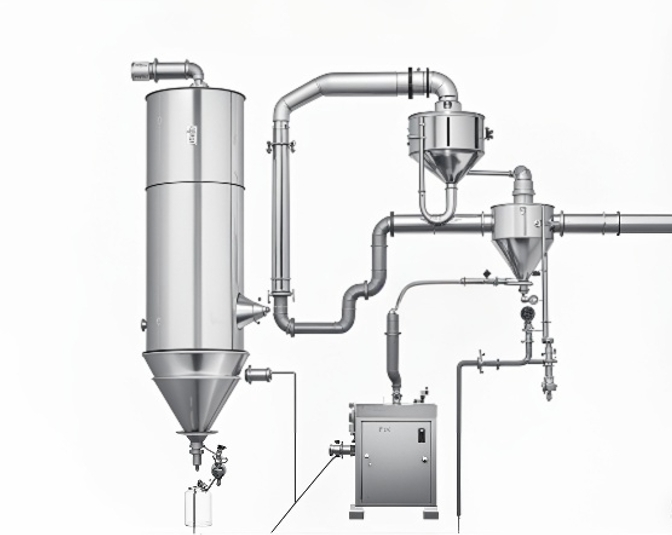

- Atomization: The liquid feed is converted into fine droplets using an atomizer or spray nozzle. The choice of atomizer can impact the droplet size, which in turn affects drying efficiency.

- Drying: The droplets are introduced into a hot air stream inside the drying chamber. As the hot air comes into contact with the droplets, moisture evaporates, leaving behind solid particles.

- Collection: The dry particles are separated from the drying air stream and collected for further processing or packaging.

Factors Affecting Spray Dryer Performance

Several factors influence the efficiency and performance of a spray dryer. Here are some of the most critical ones:

1. Inlet and Outlet Air Temperatures

2. Feed Properties

The properties of the feed material play a crucial role in the spray drying process. Factors such as viscosity, solids concentration, and temperature can affect atomization and drying efficiency. For instance, a highly viscous feed may require more energy for atomization and result in larger droplet sizes, which can affect the drying rate.

3. Atomization Method

The choice of atomization method directly influences the droplet size distribution. Common atomization techniques include rotary atomizers and pressure nozzles. Each method has its advantages and limitations, and selecting the appropriate one depends on the specific requirements of the product being dried.

4. Airflow and Air Distribution

Efficient airflow and even air distribution within the drying chamber are essential for consistent drying. Uneven air distribution can lead to non-uniform drying, affecting product quality and leading to energy inefficiencies.

5. Chamber Design

The design of the drying chamber, including its shape and size, impacts the drying process. A well-designed chamber promotes efficient heat and mass transfer, reducing drying time and energy consumption. Moreover, the chamber design should facilitate easy cleaning and maintenance to avoid contamination and ensure consistent performance.

Spray Dryer Efficiency Calculation

Calculating the efficiency of a spray dryer is vital for identifying areas of improvement and optimizing the drying process. The efficiency can be determined by comparing the actual moisture removal rate with the theoretical maximum possible rate. The formula for calculating spray dryer efficiency is:

[ \text{Efficiency} (%) = \left( \frac{\text{Actual moisture removal}}{\text{Theoretical moisture removal}} \right) \times 100 ]

Optimizing efficiency involves adjusting the factors mentioned earlier, such as air temperature, feed rate, and atomization method, to achieve the desired drying performance while minimizing energy consumption.

Enhancing Spray Dryer Efficiency

To enhance spray dryer efficiency, consider implementing the following strategies:

Regular Maintenance and Cleaning

Regular maintenance and cleaning of the spray dryer can prevent buildup and contamination, ensuring consistent performance. Inspecting and replacing worn-out components, such as nozzles and filters, can also improve efficiency.

Energy Recovery Systems

Implementing energy recovery systems, such as heat exchangers, can recover waste heat from the exhaust air and reuse it to preheat the incoming air. This can significantly reduce energy consumption and enhance overall efficiency.

Process Automation and Control

Automating the spray drying process with advanced control systems can optimize operating conditions in real-time. These systems can adjust parameters like air temperature and feed rate to maintain optimal drying conditions, improving efficiency and product quality.

Real-World Applications and Considerations

Spray drying is used in various industries, each with its specific requirements and challenges. For example, in the food industry, spray drying is used to produce milk powder, coffee, and flavorings. In pharmaceuticals, it helps create fine powders for inhalers and other drug delivery systems.

When designing and optimizing a spray drying process, it’s essential to consider the specific needs of the industry and the product. Factors such as particle size, moisture content, and thermal sensitivity must be taken into account to ensure the final product meets quality standards.

Conclusion

The performance of a spray dryer is influenced by a multitude of factors, from air temperature to feed properties and chamber design. By understanding and optimizing these factors, businesses can enhance spray dryer efficiency, reduce energy consumption, and achieve superior product quality. Regular maintenance, energy recovery systems, and advanced process control are just a few strategies that can lead to significant improvements. Whether you’re in the food, pharmaceutical, or chemical industry, a well-optimized spray drying process can be a game-changer for your operations.