Table of Contents

Product Detail

Understanding Fluidized Bed Drying Techniques

Understanding fluidized bed drying techniques can greatly enhance the efficiency and quality of industrial drying processes. This article aims to explore the principles, benefits, and applications of fluidized bed technology in various industries. By understanding how fluidized bed drying works, you can make informed decisions about whether it’s the right drying system for your needs.

Fluidized bed drying is a process used to dry materials like powders and granules. It involves suspending solid particles in an upward-flowing stream of hot air or gas. This creates a fluid-like state, allowing for efficient heat and mass transfer between the drying medium and the materials being dried.

How Does Fluidized Bed Drying Work?

In fluidized bed drying, the material to be dried is placed in a perforated or slotted bed. Hot air is blown through the bed at a high velocity, causing the particles to become suspended and behave like a fluid. This process increases the contact area between the hot air and the particles, leading to faster and more uniform drying.

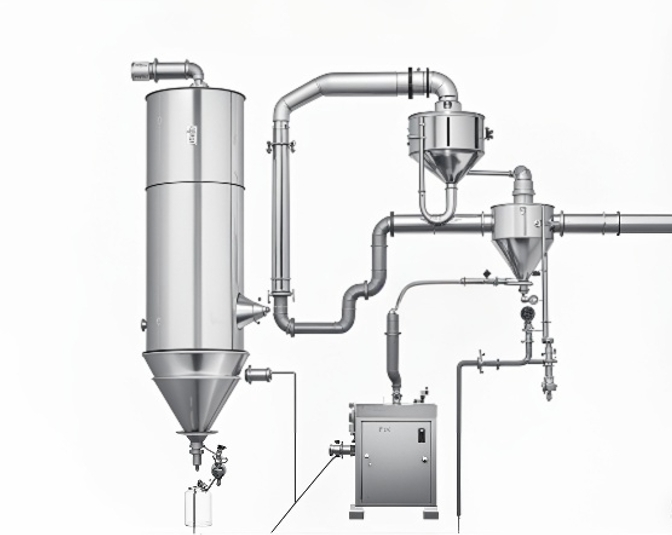

Key Components of a Fluidized Bed Dryer

A typical fluidized bed dryer consists of several key components:

- Air Distributor: Ensures uniform distribution of air across the material bed.

- Heater: Heats the air before it enters the bed.

- Exhaust System: Removes moisture-laden air from the dryer.

- Control Systems: Regulate airflow, temperature, and other parameters to optimize the drying process.

Benefits of Fluidized Bed Drying

Enhanced Drying Efficiency

The fluidized state allows for excellent heat and mass transfer, significantly reducing drying time. This efficiency results in lower energy consumption and operational costs.

Uniform Drying

The movement of particles within the fluidized bed ensures that each particle is evenly exposed to the hot air, resulting in uniform drying. This is especially beneficial for materials that are sensitive to temperature variations.

Scalability

Fluidized bed dryers can be easily scaled to meet the production demands of different industries. Whether you need a small batch dryer or a large industrial system, fluidized bed technology can be adapted to fit your needs.

Versatility

This drying technique can handle a wide range of materials, from fine powders to coarse granules. It is widely used in industries such as pharmaceuticals, food processing, and chemicals.

Applications of Fluidized Bed Drying

Fluidized bed drying is used across various industries for different applications:

Pharmaceutical Industry

In the pharmaceutical industry, fluidized bed dryers are used to dry powders, granules, and even wet mass. The uniform drying ensures consistent product quality, which is crucial for pharmaceutical products.

Food Processing

In food processing, fluidized bed drying is used to dry cereals, vegetables, and other food products. The gentle drying process helps maintain the nutritional and sensory qualities of the food.

Chemical Industry

For the chemical industry, fluidized bed drying is used to dry a variety of chemicals, ensuring they meet the desired specifications. The process can handle heat-sensitive materials without degrading their properties.

Choosing the Right Fluidized Bed Dryer

When selecting a fluidized bed dryer, consider the following factors:

Material Characteristics

Understand the properties of the material you need to dry. Factors such as particle size, moisture content, and thermal sensitivity can affect the choice of dryer.

Production Requirements

Consider your production scale and capacity needs. Choose a dryer that can handle your volume requirements without compromising on efficiency or quality.

Energy Efficiency

Look for dryers with energy-saving features. Efficient dryers can significantly reduce operational costs and environmental impact.

Control Systems

Advanced control systems can enhance the precision and reliability of the drying process. Ensure the dryer you choose has the necessary controls to meet your quality standards.

Maintenance and Safety Considerations

Proper maintenance and safety protocols are essential for the efficient operation of fluidized bed dryers:

Regular Maintenance

Schedule regular maintenance checks to ensure the dryer is functioning optimally. This includes inspecting components, cleaning air filters, and checking for wear and tear.

Safety Measures

Implement safety measures to prevent accidents. This includes ensuring proper ventilation, monitoring temperature and pressure levels, and training staff on safe operating procedures.

Conclusion

Fluidized bed drying is a versatile and efficient technique for drying various materials. By understanding its principles and applications, you can determine if it’s the right solution for your industrial drying needs. Whether you’re in pharmaceuticals, food processing, or chemicals, fluidized bed technology can enhance your drying process, leading to improved product quality and reduced costs.

Specifications

|

Model

|

Area of fluidized-bed

(㎡) |

Temperature of inlet air (P)

|

Temperature of outlet (°C)

|

Capacity to vapor moisture(kg/h)

|

Vibration motor

|

|

|

Model

|

Power kw

|

|||||

|

ZDG3x0.30

|

0.9

|

70 to 140 |

40 to 70 |

20 ~ 35

|

YZS8-6

|

0.75×2

|

|

ZDG4.5×0.30

|

1.35

|

35 ~ 50

|

YZS10-6

|

0.75×2

|

||

|

ZDG4.5×0.45

|

2.025

|

50 ~ 70

|

YZS15-6

|

1.1×2

|

||

|

ZDG4.5×0.60

|

2.7

|

70 ~ 90

|

YZS15-6

|

1.1×2

|

||

|

ZDG6x0.45

|

2.7

|

80 ~ 100

|

YZS15-6

|

1.5×2

|

||

|

ZDG6x0.60

|

3.6

|

100 ~ 130

|

YZS20-6

|

1.5×2

|

||

|

ZDG6x0.75

|

4.5

|

120 ~ 170

|

YZS20-6

|

2.2×2

|

||

|

ZDG6x0.9

|

5.4

|

140 ~ 170

|

YZS30-6

|

2.2×2

|

||

|

ZDG7.5×0.6

|

4.5

|

130 ~ 150

|

YZS30-6

|

2.2×2

|

||

|

ZDG7.5×0.75

|

5.625

|

150 ~ 180

|

YZS40-6

|

3.0×2

|

||

|

ZDG7.5×0.9

|

6.75

|

160 ~ 210

|

YZS40-6

|

3.0×2

|

||

|

ZDG7.5x 1.2

|

9.0

|

200 ~ 280

|

YZS50-6

|

3.7×2

|

||

|

ZDG7.5x 1.5

|

11.25

|

230 ~ 330

|

YZS50-6

|

3.7×2

|

||

|

ZDG8x 1.8

|

14.4

|

290 ~ 420

|

YZS75-6

|

5.5×2

|

||

Applications

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Retail, Energy & Mining, Food & Beverage Shops