جدول المحتويات

تفاصيل المنتج

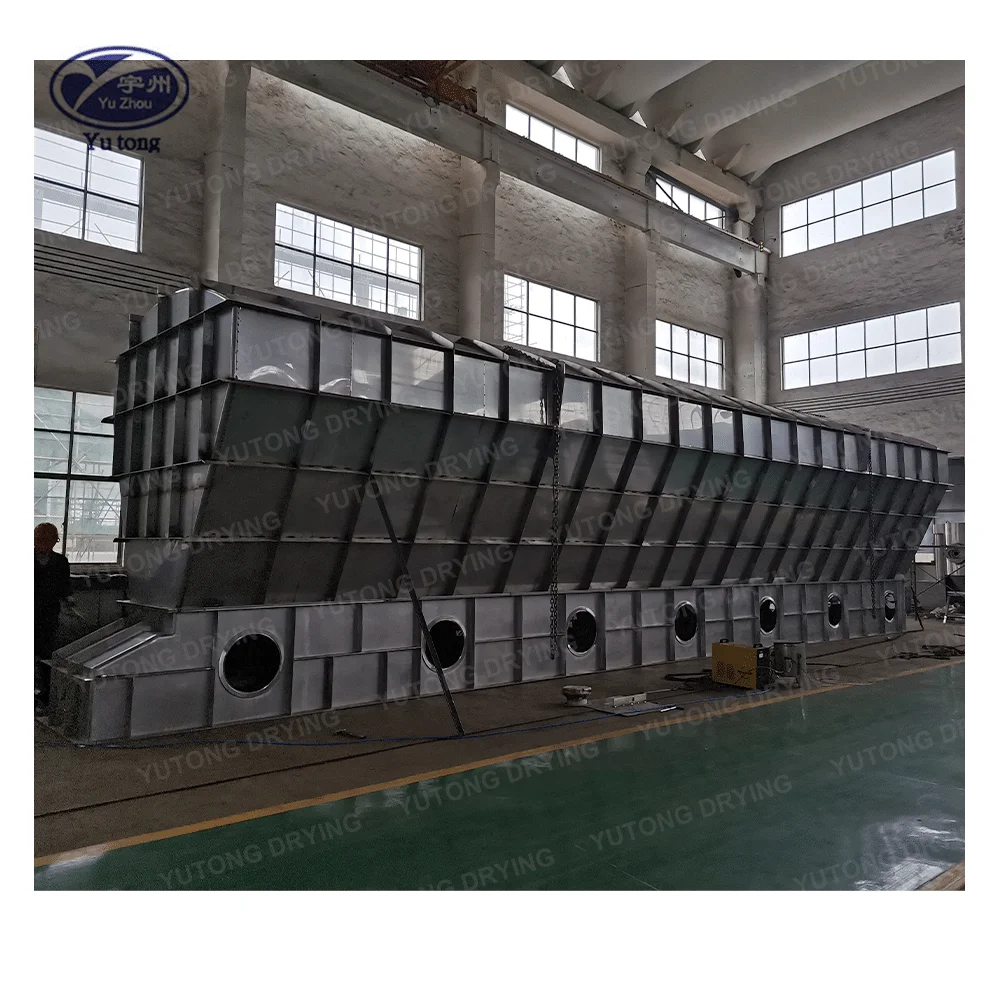

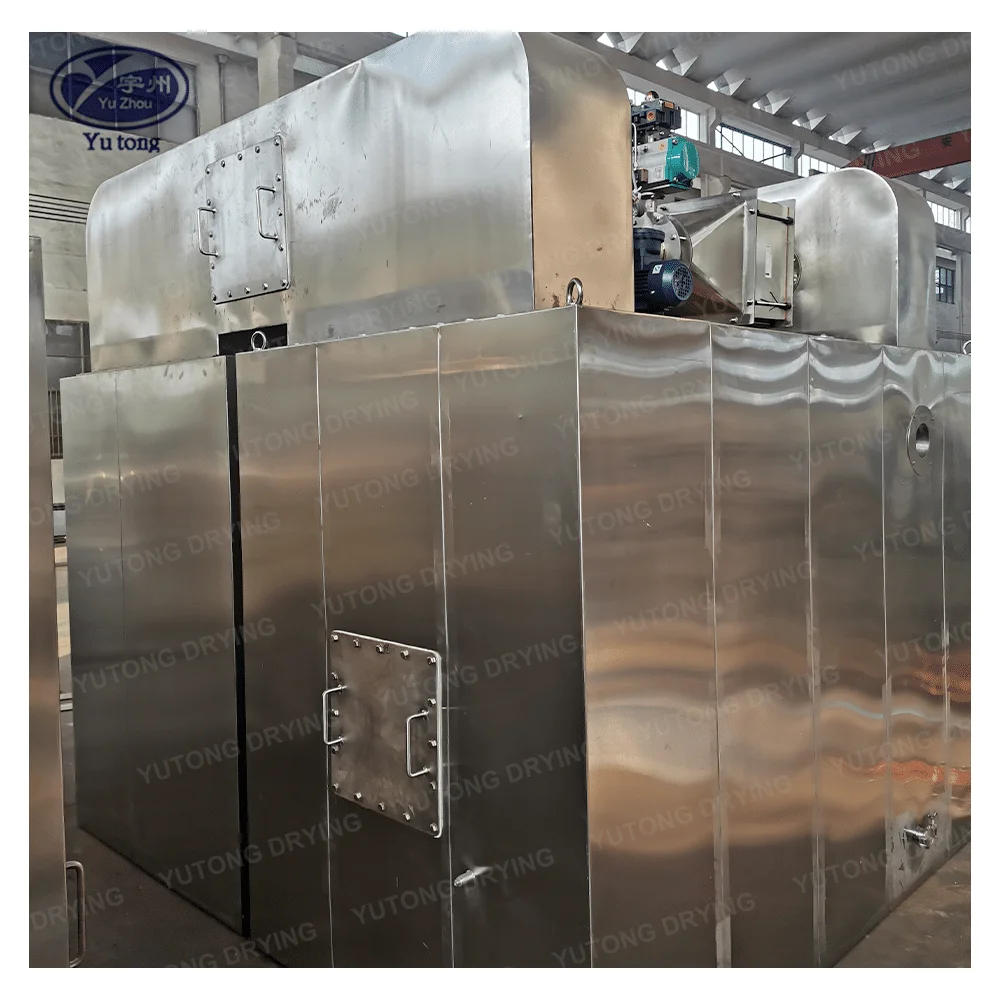

مجفف السرير المميع هو حل تجفيف عالي الكفاءة ومتعدد الاستخدامات، يُستخدم على نطاق واسع في مختلف الصناعات. وهو مناسب بشكل خاص لتجفيف المساحيق والحبيبات والمواد البلورية. تضمن عملية التجفيف توزيعًا متساويًا للحرارة وتحسين الكفاءة الحرارية من خلال تعليق المادة في تيار من الهواء الساخن، مما يعزز نقل الكتلة والحرارة.

الميزات الرئيسية:

- كفاءة عالية: تجفيف سريع مع الحد الأدنى من استهلاك الطاقة بسبب توزيع الهواء الموحد والسوائل.

- جودة المنتج ثابتة: يحافظ على حجم الجسيمات ونسبة الرطوبة موحدة.

- متعدد الوظائف: قادرة على التجفيف، والتبريد، والتحبيب، أو الطلاء في عملية واحدة.

- طرق التدفئة المرنة: متوافق مع أنظمة التدفئة الكهربائية أو البخارية.

- متوافق مع ممارسات التصنيع الجيدة: تصميم صحي مع سهولة التنظيف، ومناسب للتطبيقات الصيدلانية والغذائية.

- التشغيل الآمن: مجهزة بأنظمة تخفيف الانفجار وأقمشة ترشيح مضادة للكهرباء الساكنة لضمان سلامة المشغل.

التطبيقات:

- صناعة الأدوية: تجفيف الحبيبات الرطبة والمسحوق للأقراص أو الكبسولات.

- صناعة الأغذية: معالجة المنتجات مثل القهوة والكاكاو ومسحوق الحليب والنكهات والتوابل.

- الصناعة الكيميائية: تستخدم في صناعة الأسمدة والمبيدات الحشرية والأصباغ والراتنجات.

- صناعة الأعلاف: تجفيف الأعلاف الحيوانية والمواد المضافة.

- صناعة البلاستيك: تجفيف الحبيبات البلاستيكية والراتنجات البلاستيكية الحرارية.

| يكتب | مساحة السرير (م³) | تجفيف | الطاقة (كيلوواط) | ضغط الهواء (باسكال) | حجم الهواء (م³/ساعة) | مدخل الهواء | مادة | استهلاك طاقة التدفئة | استهلاك طاقة التدفئة الطاقة الكهربائية (كيلوواط) |

| سعة | درجة الحرارة (درجة مئوية) | تسريح | البخار (كجم/ساعة) | ||||||

| (ماء كجم/ساعة) | درجة الحرارة (درجة مئوية) | ||||||||

| XF-10A | 0.25 | 5.5 | 4900 | 2300 | 60~140 | 40~80 | |||

| 10~15 | |||||||||

| 50 | 30 | ||||||||

| XF-10B | 0.25 | 4 | 3800 | 2300 | |||||

| XF-20A | 0.5 | 7.5 | 5000 | 3100 | |||||

| 20~25 | 100 | 60 | |||||||

| XF-20B | 0.5 | 5.5 | 3500 | 3100 | |||||

| XF-30A | 1 | 15 | 6000 | 4200 | |||||

| 30~45 | 150 | 90 | |||||||

| XF-30B | 1 | 11 | 4700 | 4200 | |||||

| XF-50A | 2 | 22 | 7400 | 6000 | |||||

| 50~80 | 250 | 150 | |||||||

| XF-50B | 2 | 18.5 | 5900 | 6000 |

تحديد

| يكتب | مساحة السرير (م³) | تجفيف | الطاقة (كيلوواط) | ضغط الهواء (باسكال) | حجم الهواء (م³/ساعة) | مدخل الهواء | مادة | استهلاك طاقة التدفئة | استهلاك طاقة التدفئة الطاقة الكهربائية (كيلوواط) |

| سعة | درجة الحرارة (درجة مئوية) | تسريح | البخار (كجم/ساعة) | ||||||

| (ماء كجم/ساعة) | درجة الحرارة (درجة مئوية) | ||||||||

| XF-10A | 0.25 | 5.5 | 4900 | 2300 | 60~140 | 40~80 | |||

| 10~15 | |||||||||

| 50 | 30 | ||||||||

| XF-10B | 0.25 | 4 | 3800 | 2300 | |||||

| XF-20A | 0.5 | 7.5 | 5000 | 3100 | |||||

| 20~25 | 100 | 60 | |||||||

| XF-20B | 0.5 | 5.5 | 3500 | 3100 | |||||

| XF-30A | 1 | 15 | 6000 | 4200 | |||||

| 30~45 | 150 | 90 | |||||||

| XF-30B | 1 | 11 | 4700 | 4200 | |||||

| XF-50A | 2 | 22 | 7400 | 6000 | |||||

| 50~80 | 250 | 150 | |||||||

| XF-50B | 2 | 18.5 | 5900 | 6000 |

التطبيقات

المستحضرات الصيدلانية: تجفيف الحبيبات الرطبة والمسحوق قبل ضغط الأقراص.

صناعة الأغذية: مثالية لمسحوق الحليب، وحبيبات القهوة، والنكهات، ومستخلصات الفاكهة.

الصناعة الكيميائية: فعالة لتجفيف الأصباغ والراتنجات والأسمدة.

الزراعة: تجفيف الحبوب والبذور ومكونات الأعلاف الحيوانية.