Spray drying is a powerful technique used across various industries to transform liquid substances into dry powders. This process is crucial for producing a wide range of products, from food and pharmaceuticals to chemicals and ceramics. To ensure optimal performance and efficiency, it’s vital to size your spray dryer correctly. This comprehensive guide will walk you through the essential aspects of spray dryer sizing, design factors, and performance considerations.

What is Spray Dryer Performance?

Spray dryer performance refers to how effectively the dryer converts liquid feed into dry powder. Several factors influence this performance, including the feed rate, temperature, and the design of the dryer itself. A well-performing spray dryer will produce a consistent, high-quality product while minimizing energy consumption and waste.

Factors Affecting Spray Dryer Efficiency

Efficiency in a spray drying process is about maximizing output while minimizing energy use and material waste. Key factors affecting efficiency include:

- Inlet and Outlet Temperatures: The temperature difference between the inlet and outlet affects drying efficiency. Higher inlet temperatures can increase drying rates but may risk damaging heat-sensitive materials.

- Airflow Patterns: The design of the airflow within the dryer impacts how effectively the heat is transferred to the particles.

- Atomization: The method of converting the liquid into a fine spray (atomization) plays a critical role in determining the size and moisture content of the final product.

Spray Dryer Capacity: Ensuring Adequate Throughput

Determining Spray Dryer Capacity

The volume of liquid feed determines the capacity of a spray dryer it can process over a given time. This depends on the dryer’s size, the feed properties, and the drying conditions.

Factors Influencing Capacity

- Feed Rate: The rate at which the liquid is fed into the dryer significantly impacts its capacity. Higher feed rates require larger or more efficient dryers.

- Moisture Content: The initial moisture content of the feed determines the amount of water that needs to be evaporated.

- Powder Properties: The desired properties of the final product, such as particle size and moisture content, will influence the required capacity.

Key Spray Dryer Design Factors

Critical Design Considerations

When designing a spray dryer, several factors must be considered to ensure it meets the specific needs of your process:

- Chamber Size and Shape: The size and shape of the drying chamber affect the residence time of the particles and the overall efficiency of the drying process.

- Atomizer Type: Different atomizers, such as rotary or nozzle, are suitable for various applications and affect the droplet size and distribution.

- Heat Source and Control: The heat source must be appropriately sized to provide the necessary energy for evaporation without overheating the product.

Matching Design to Application

Selecting the right design involves balancing the specific requirements of your process with the capabilities of the spray dryer. Considerations include the product’s thermal sensitivity, the desired particle size, and the need for specific powder characteristics.

Specifications for Optimal Spray Dryer Sizing

Essential Specifications

To size a spray dryer correctly, you must consider several critical specifications:

- Evaporation Rate: The amount of water or solvent that needs to be evaporated per hour.

- Particle Size Distribution: The range of particle sizes required for your final product.

- Temperature Profiles: The necessary inlet and outlet temperatures for effective drying.

- Residence Time: The time the particles remain in the dryer, affecting the moisture content and final particle characteristics.

Customizing Specifications for Different Industries

Different industries have unique requirements for spray drying. For example, the food industry often demands stringent hygiene and safety standards, while the pharmaceutical industry may focus on precise particle size and moisture content. Customizing specifications to meet these demands ensures optimal dryer performance.

The Spray Drying Process: Sizing for Success

خطوات عملية التجفيف بالرش

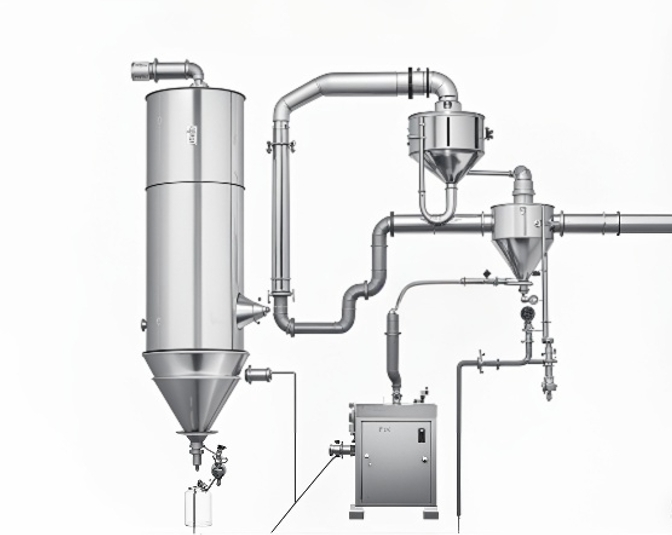

- Atomization: Liquid feed is broken down into fine droplets.

- Drying: The droplets are exposed to hot air, rapidly evaporating the moisture.

- Separation: The dry particles are separated from the air stream and collected.

Importance of Proper Sizing

Proper sizing of the spray dryer is crucial for ensuring each step of the process operates efficiently. Undersized dryers may struggle to process the required volume, while oversized dryers can lead to unnecessary energy consumption and costs.

Conclusion: Optimizing Your Spray Dryer for Performance and Efficiency

Spray dryer sizing is a complex but vital aspect of optimizing the spray drying process. By understanding the factors that influence performance, capacity, and efficiency, you can design and specify a dryer that meets your needs and maximizes productivity.

Whether you’re in food production, pharmaceuticals, or any other industry reliant on spray drying, investing in the right size and design of your spray dryer can lead to significant improvements in product quality and operational efficiency.