Inhaltsverzeichnis

Produktdetail

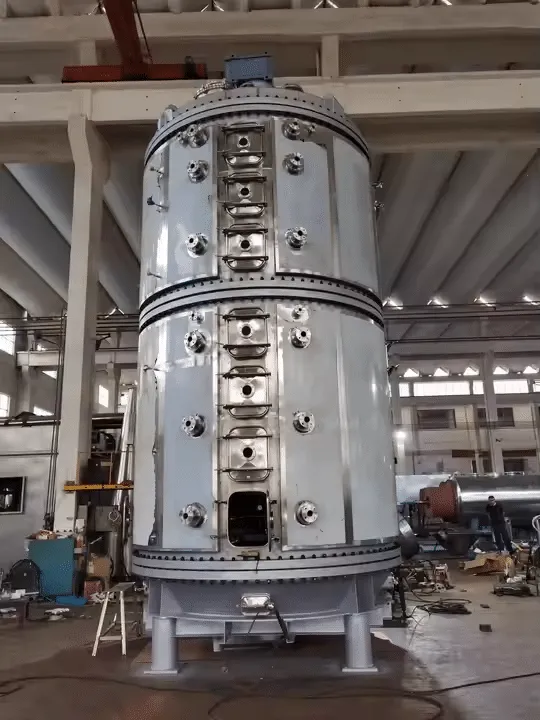

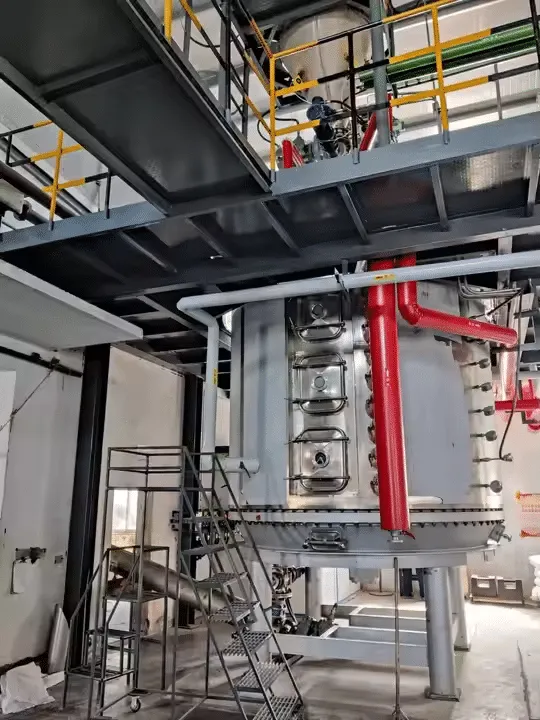

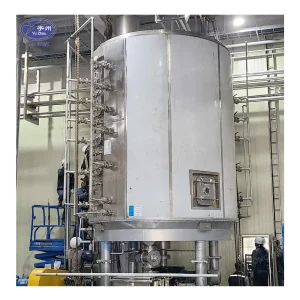

The Chemical Process Vacuum Dryer is a specialized drying solution designed to meet the rigorous demands of chemical production environments. Engineered for safe and efficient moisture removal from sensitive, heat-sensitive, or volatile compounds, this dryer plays a vital role in process optimization.

Hauptmerkmale:

-

Vacuum Drying Technology: Enables low-temperature drying to prevent decomposition or oxidation of reactive or heat-sensitive chemicals.

-

Hohe Effizienz: Accelerates drying cycles with optimized heat and mass transfer under vacuum conditions.

-

Explosion-Proof & Corrosion-Resistant Design: Built with chemical-grade stainless steel and optional explosion-proof components for handling hazardous substances.

-

Precise Control System: Advanced control interface for setting temperature, vacuum level, and drying time with high accuracy.

-

Scalable Design: Available in lab-scale, pilot, and full production capacities to suit different chemical process needs.

-

Closed-System Operation: Minimizes solvent loss, protects operators, and maintains a clean production environment.

Technische Daten

| Technische Daten | Außendurchmesser (mm) | Höhe (mm) | Trocknungsfläche (m2) | Leistung (kw) |

| 1200/4 | 1850 | 2608 | 3.3 | 1.1 |

| 1200/6 | 3028 | 4.9 | ||

| 1200/8 | 3448 | 6.6 | 1.5 | |

| 1200/10 | 3868 | 8.2 | ||

| 1200/12 | 4288 | 9.9 | ||

| 1500/6 | 2100 | 3022 | 8 | 2.2 |

| 1500/8 | 3442 | 10.7 | ||

| 1500/10 | 3862 | 13.4 | ||

| 1500/12 | 4282 | 16.1 | 3 | |

| 1500/14 | 4702 | 18.8 | ||

| 1500/16 | 5122 | 21.5 | ||

| Jun-00 | 2900 | 3262 | 18.5 | 3 |

| Aug-00 | 3682 | 24.6 | ||

| Oct-00 | 4102 | 30.8 | ||

| Dec-00 | 4522 | 36.9 | 4 | |

| 2200/14 | 4942 | 43.1 | 5 | |

| 2200/16 | 5362 | 49.3 | ||

| Aug-00 | 2900 | 5782 | 55.4 | 5.5 |

| 2200/20 | 6202 | 61.6 | ||

| 2200/22 | 6622 | 67.6 | 7.5 | |

| 2200/24 | 7042 | 73.9 | ||

| 2200/26 | 7462 | 80 | ||

| Aug-00 | 3800 | 4050 | 48 | 11 |

| Oct-00 | 4650 | 60 | ||

| Dec-00 | 5250 | 72 | ||

| 3000/14 | 5850 | 84 | ||

| 3000/16 | 6450 | 96 | ||

| 3000/18 | 7050 | 108 | 13 | |

| 3000/20 | 7650 | 120 | ||

| 3000/22 | 8250 | 132 | ||

| 3000/24 | 8850 | 144 | ||

| 3000/26 | 9450 | 156 | 15 | |

| 3000/28 | 10050 | 168 | ||

| 3000/30 | 10650 | 180 |

Anwendungen

Der kontinuierliche Plattentrockner PLG eignet sich zum Trocknen, Kalzinieren, Pyrolysieren, Kühlen, Reagieren und Sublimieren in der Chemie-, Pestizid-, Lebensmittel- und Agrarindustrie. Diese Trocknungsmaschine wird hauptsächlich in folgenden Bereichen eingesetzt:

1. Organische chemische Produkte: Harz, Melamin, Anilin, Stearat, Calciumformiat und andere organische chemische Stoffe und

dazwischenliegend

2. Anorganische chemische Produkte: Calciumcarbonat, Magnesiumcarbonat, Weißruß, Natriumchlorid, Kryolith, verschiedene

Sulfat und Hydroxid

3. Lebensmittel: Cephalosporin, Vitamin, Salz, Aluminiumhydroxid, Tee, Ginkgoblätter und Stärke

4. Futtermittel und Düngemittel: biologischer Kalidünger, Eiweißfuttermittel, Getreide, Saatgut, Herbizid und Zellulose