Projektübersicht:

Koffein, ein Xanthin-basiertes Alkaloid, wirkt als starkes Stimulans des zentralen Nervensystems und ist bekannt für seine Fähigkeit, die Wachsamkeit zu steigern und Müdigkeit zu reduzieren. Der speziell für Koffein entwickelte Scheibentrockner ist ein hocheffizientes, kontinuierliches Konduktionstrocknungssystem. Sein fortschrittliches Design und seine Funktionsweise sorgen für außergewöhnliche Wärmeleistung, minimalen Energieverbrauch, kompakte Stellfläche, optimierte Konfiguration sowie einfache Bedienung und Wartung – und machen ihn zu einer bevorzugten Wahl in vielen Branchen.

Funktionsübersicht Koffein:

Koffein kommt natürlicherweise in Kaffee, Tee, Energydrinks und Erfrischungsgetränken vor und ist damit eine der weltweit am häufigsten konsumierten psychoaktiven Substanzen. Allein in Nordamerika konsumieren täglich etwa 901 Millionen Erwachsene Koffein. Neben Koffein selbst enthalten natürliche Quellen oft auch andere verwandte Verbindungen wie Theobromin und Theophyllin sowie sekundäre Substanzen wie Tannine. Diese Komponenten tragen gemeinsam zu den physiologischen und stimulierenden Wirkungen koffeinhaltiger Produkte bei.

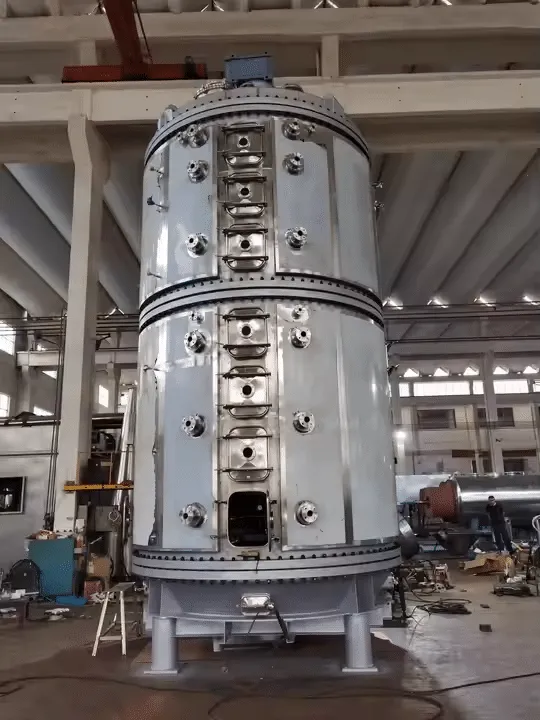

Überblick über den Koffein-Scheibentrockner:

Der speziell für Koffein entwickelte Scheibentrockner ist auf effiziente Wärmeleitung und kontinuierliche Trocknung ausgelegt. Sein konstruktiver Aufbau gewährleistet eine hohe Wärmeübertragungseffizienz, reduzierten Energieverbrauch und minimalen Installationsraum. Das Gerät zeichnet sich durch eine benutzerfreundliche Oberfläche, einen stabilen Betrieb und eine saubere Arbeitsumgebung aus. Dank dieser Vorteile findet das Gerät breite Anwendung in Branchen wie der Pharma-, Chemie- und Agrochemieindustrie, der Lebensmittelverarbeitung, der Futtermittelproduktion und der Trocknung landwirtschaftlicher Produkte.

Dieser Trockner ist in mehreren Konfigurationen erhältlich, um unterschiedlichen Anwendungsanforderungen gerecht zu werden:

-

Arten: Atmosphärische, versiegelte und Vakuummodelle.

-

Größen: Standardmodelle umfassen Platten mit 1200 mm, 1500 mm, 2200 mm und 3000 mm Durchmesser.

-

Materialqualitäten:

-

Typ A: Konstruktion aus Kohlenstoffstahl.

-

Typ B: Kontaktflächen aus Edelstahl.

-

Typ C: Basierend auf Typ B, mit zusätzlichen Dampfleitungen, zentraler Welle, Stützstruktur, innerer Kammerauskleidung und Abdeckplatte aus Edelstahl.

-

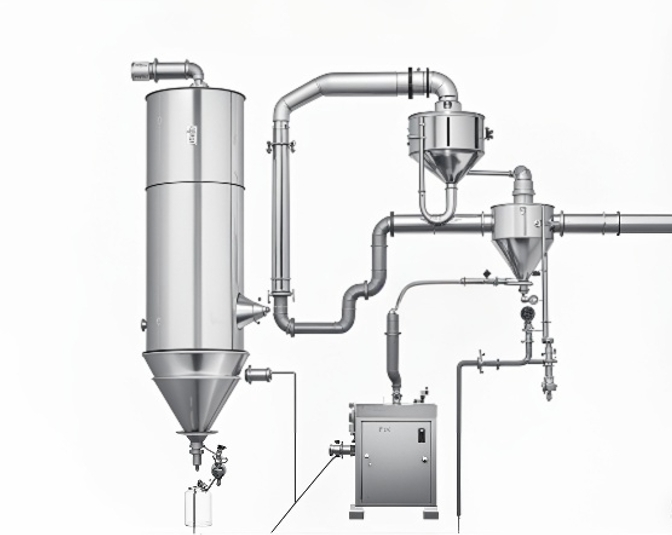

Die Trocknungsflächen reichen von 4 bis 180 m², die eine Vielzahl von Prozesskapazitäten unterstützen. Darüber hinaus steht eine umfassende Palette an Zusatzgeräten für eine nahtlose Systemintegration zur Verfügung, die optimale Leistung für ein breites Materialspektrum gewährleistet.