Spray drying is a fascinating and essential process in various industries, from pharmaceuticals to food production. At the heart of this process lies the spray dryer, a piece of equipment that transforms liquid solutions into dry powders. In this article, we delve into the world of laboratory spray dryers, explore their benefits, and understand why they are indispensable in both research and production settings.

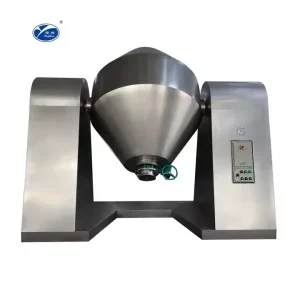

A laboratory spray dryer is a scaled-down version of an industrial spray dryer, designed for research and development purposes. It operates on the same principles but is compact enough to fit in a laboratory setting. The primary function of a laboratory Sprühtrockner is to convert a liquid feed into a dry powder quickly and efficiently.

How Does the Spray Drying Process Work?

Der Sprühtrocknungsverfahren involves three main stages: atomization, drying, and collection. Here’s a brief overview of each stage:

- Atomization: The liquid feed is transformed into fine droplets through a nozzle or atomizer. This increases the surface area, allowing for rapid drying.

- Drying: The atomized droplets are introduced into a chamber with hot air. As the droplets travel through the chamber, the moisture evaporates, leaving behind dry particles.

- Collection: The dried particles are collected in a cyclone separator or a collection vessel, ready for further use.

Advantages of Using Laboratory Spray Dryers

Laboratory spray dryers offer several advantages that make them a popular choice in research and development. Let’s explore some of these benefits.

Präzision und Kontrolle

One of the standout features of laboratory spray dryers is the precision and control they offer. Researchers can fine-tune various parameters such as temperature, air flow, and feed rate to achieve specific particle sizes and moisture content. This level of control is crucial when developing new products or optimizing existing ones.

Versatility in Application

Laboratory spray dryers are incredibly versatile and can handle a wide range of materials, from heat-sensitive pharmaceuticals to robust chemicals. This adaptability makes them suitable for various industries, including food, pharmaceuticals, ceramics, and more.

Rapid Drying Times

Der Sprühtrocknungsverfahren is known for its rapid drying times, which is a significant advantage in a laboratory setting. Quick drying not only speeds up research and development but also helps maintain the integrity of heat-sensitive materials.

Scalability for Industrial Application

While laboratory spray dryers are designed for small-scale production, they provide valuable insights for scaling up to industrial spray dryers. Researchers can test formulations and processes on a smaller scale before committing to large-scale production, reducing risks and costs.

Consistent and Homogeneous Products

Spray drying produces consistent and homogeneous powders, which is essential for product quality and performance. This consistency is achieved through the controlled drying environment and precise parameter adjustments.

Real-World Applications of Laboratory Spray Dryers

Laboratory spray dryers find applications across various industries, each with its unique requirements and challenges. Let’s look at some real-world examples.

Pharmaindustrie

In the pharmaceutical industry, spray drying is used to create stable and bioavailable drug formulations. Laboratory spray dryers allow researchers to test different formulations and optimize drug delivery systems.

Lebensmittelindustrie

In the food industry, spray drying is employed to produce powdered ingredients like milk powder, coffee, and flavorings. Laboratory spray dryers enable food scientists to experiment with new recipes and enhance product stability.

Chemical and Material Science

In chemical and material science, Sprühtrocknung is used to synthesize fine powders for various applications, from catalysts to ceramics. Laboratory spray dryers provide the precision needed to develop new materials with specific properties.

Choosing the Right Laboratory Spray Dryer

Selecting the right laboratory Sprühtrockner depends on several factors, including the type of material, desired particle size, and budget. Here are some key considerations:

- Capacity: Ensure the dryer can handle the volume of material you need to process.

- Temperature Control: Look for a dryer with precise temperature control to protect heat-sensitive materials.

- Ease of Use: Consider a user-friendly design with easy setup and operation.

- Maintenance: Check for easy maintenance and cleaning to ensure longevity.

Future Trends in Spray Drying Technology

As technology advances, so does the field of Sprühtrocknung. Here are some future trends to watch for:

Energieeffizienz

Improving energy efficiency is a priority, with innovations aimed at reducing energy consumption and environmental impact.

Verbesserte Steuerungssysteme

Advanced control systems are being developed to provide even greater precision and automation in the Sprühtrocknungsverfahren.

Novel Materials and Applications

Researchers are exploring new materials and applications, pushing the boundaries of what can be achieved with spray drying technology.

Abschluss

Laboratory spray dryers are indispensable tools in research and development across various industries. Their precision, versatility, and scalability make them an essential piece of equipment for anyone looking to develop new products or optimize existing ones. As technology continues to evolve, the potential for spray drying technology only grows, promising exciting developments in the years to come.