Tabla de contenido

Detalle del producto

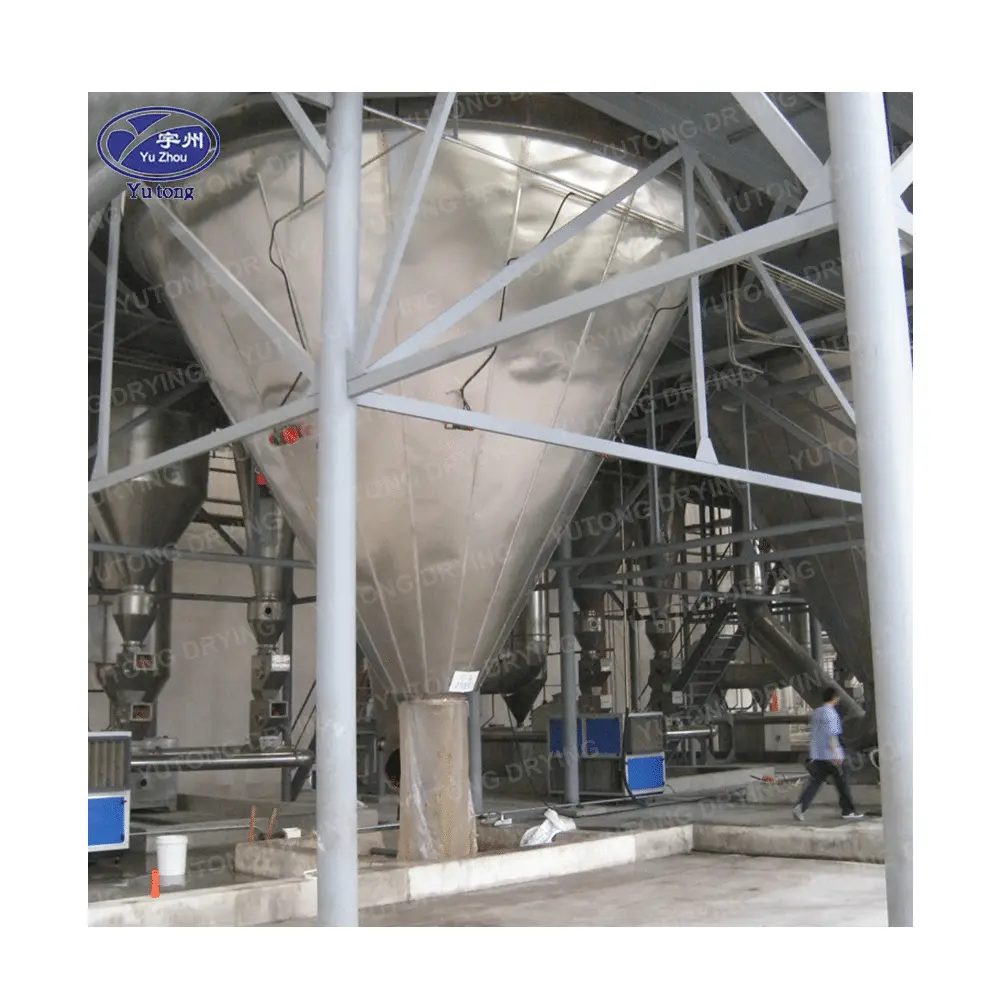

secador por pulverización de huevo en polvo

En el cambiante panorama de la tecnología alimentaria, el huevo en polvo ha cobrado relevancia como ingrediente versátil, ofreciendo importantes ventajas en términos de almacenamiento, vida útil y una amplia gama de aplicaciones. Un elemento clave de esta transformación es el secador por aspersión de huevo en polvo, un equipo esencial que convierte el huevo líquido en polvo. Este artículo profundiza en las complejidades de los secadores por aspersión de huevo en polvo, sus múltiples aplicaciones y dónde encontrarlos, especialmente en Río de Janeiro.

Benefits of Using Egg Powder Spray Dryers

In today’s fast-paced food industry, efficiency and quality are paramount. The rapid evolution of technology has introduced innovative solutions that have revolutionized food processing. One such advancement is the egg powder spray dryer. This sophisticated equipment plays a vital role in converting liquid egg into a stable, easy-to-use powder form. Let’s explore the numerous benefits of using egg powder spray dryers and understand why they are indispensable for food processors worldwide.

What is an Egg Powder Spray Dryer?

An egg powder spray dryer is a specialized piece of equipment designed to transform liquid egg into powdered form through a process known as spray drying. This process involves intricate technology that ensures the preservation of nutritional value and functional properties of the egg.

El proceso de secado por aspersión

Spray drying is an intricate process that involves converting liquid into powder through rapid drying. This is achieved by spraying the liquid egg into a hot chamber, where it dries almost instantly. The result is a fine, consistent powder that retains the original properties of the egg. The precision of this process is what makes it so valuable in the food industry.

Mantener la integridad nutricional

One of the primary advantages of using an egg powder spray dryer is its ability to maintain the nutritional integrity of the egg. The process is designed to ensure that essential nutrients like proteins, vitamins, and minerals remain intact. This is particularly important for manufacturers focused on producing high-quality, nutritious food products.

Technological Advancements in Spray Dryers

Over the years, advancements in spray drying technology have enhanced the efficiency and effectiveness of egg powder production. Modern spray dryers are equipped with sophisticated controls and monitoring systems that ensure optimal drying conditions. These technological innovations contribute to producing a superior product with consistent quality.

Advantages of Egg Powder Spray Dryers

Egg powder spray dryers offer a multitude of benefits that make them an attractive option for food manufacturers. From enhanced shelf life to cost savings, these dryers have transformed the way eggs are processed and utilized in various applications.

Enhanced Shelf Life and Storage

One of the most significant advantages of egg powder is its extended shelf life. Unlike liquid eggs that require refrigeration and are prone to spoilage, egg powder can be stored at room temperature for extended periods without losing quality. This stability reduces the need for refrigeration, thereby lowering energy consumption and storage costs.

Convenience for Manufacturers

The convenience of storing egg powder at ambient temperatures allows manufacturers to streamline their operations. With no requirement for specialized storage facilities, businesses can save on infrastructure costs. This flexibility also enables manufacturers to meet fluctuating demand without the pressure of immediate consumption.

Reduction in Food Waste

The extended shelf life of egg powder contributes significantly to reducing food waste. Unlike liquid eggs that have a short shelf life, powdered eggs can be used as needed, minimizing waste due to spoilage. This not only benefits the manufacturer but also aligns with global sustainability goals.

Cost-Effective Inventory Management

With egg powder, inventory management becomes more efficient and cost-effective. Manufacturers can maintain larger stocks without the risk of spoilage, allowing for better planning and reduced frequency of ordering. This leads to cost savings in logistics and supply chain management.

Calidad de producto constante

Egg powder spray dryers are engineered to produce a consistent product with uniform particle size and moisture content. This consistency is vital for food manufacturers who rely on precise measurements for recipes and formulations.

Uniformidad en la producción

Consistency in egg powder production ensures that every batch meets the same quality standards. This uniformity is crucial for maintaining brand reputation and consumer trust. Manufacturers can confidently produce products that meet stringent quality requirements.

Precision in Formulations

The uniform nature of egg powder allows manufacturers to achieve precise formulations in their products. Whether it’s for baking, sauces, or other applications, the consistent quality of egg powder ensures that the final product meets the desired specifications every time.

Seguro de calidad

Egg powder spray dryers are designed with quality assurance in mind. Advanced monitoring systems and controls ensure that every aspect of the drying process is optimized for quality. This attention to detail results in a product that consistently meets high standards.

Solución rentable

Implementing spray dryer equipment is a cost-effective solution for food manufacturers. The efficiency of the process reduces energy consumption and minimizes waste, leading to significant cost savings.

Eficiencia energética

Spray drying technology is designed to be energy-efficient, making it a sustainable choice for manufacturers. The rapid drying process minimizes energy usage, reducing operational costs and contributing to environmental sustainability.

Reduction in Waste

The precision of spray drying minimizes waste during production. By converting liquid egg to powder efficiently, manufacturers can maximize yield and reduce the amount of material that goes to waste. This efficiency translates to cost savings and a more sustainable production process.

Long-Term Financial Benefits

Investing in spray drying technology offers long-term financial benefits. The reduced need for frequent restocking, coupled with savings in energy and waste management, results in a favorable return on investment for manufacturers.

Versatilidad en aplicaciones

Egg powder produced through spray drying technology is incredibly versatile, making it suitable for a wide range of food products.

Extensive Range of Uses

From baked goods to sauces, dressings, and pasta, egg powder can be used in numerous applications. Its versatility makes it a valuable ingredient for food manufacturers seeking to diversify their product offerings.

Ease of Incorporation

The ease of using egg powder simplifies the manufacturing process. Its stable nature allows for easy incorporation into recipes, reducing preparation time and effort. This efficiency is particularly beneficial for large-scale operations.

Adaptability to Market Trends

As consumer preferences evolve, manufacturers can leverage the versatility of egg powder to adapt to new trends. Whether it’s creating gluten-free, organic, or specialty products, the adaptability of egg powder provides manufacturers with the flexibility to innovate.

The Role of Egg Powder Spray Dryers in the Food Industry

Egg powder spray dryers have become a staple in the food industry, serving a variety of applications across different regions and types of food processors.

Global Reach and Applications

The use of egg powder spray dryers is not restricted to a specific region or scale of operation. From large industrial operations to small artisanal producers, spray dryers are integral to maintaining product quality and meeting consumer demand worldwide.

Industrial Scale Operations

In large-scale food manufacturing, spray dryers play a crucial role in ensuring efficient production. The ability to produce large quantities of consistent product is essential for meeting the demands of a global market.

Artisanal and Local Producers

Even smaller producers benefit from spray drying technology. The ability to produce high-quality egg powder allows artisanal manufacturers to offer premium products without compromising on quality or shelf life.

Regional Variations and Customization

Spray drying technology allows for regional customization, enabling manufacturers to cater to local tastes and preferences. This adaptability ensures that products resonate with consumers in diverse markets.

Environmental Impact and Sustainability

Spray drying technology is more environmentally friendly compared to other drying methods, contributing to sustainable food production practices.

Conservación de energía

The energy-efficient nature of spray drying reduces the environmental impact of production. By using less energy, manufacturers can lower their carbon footprint and contribute to global sustainability efforts.

Reduction in Carbon Footprint

Spray dryers are designed to minimize emissions and waste, resulting in a smaller carbon footprint. This aligns with the growing demand for environmentally responsible manufacturing practices.

Contribution to Sustainable Practices

By extending the shelf life of eggs and reducing food waste, spray drying technology supports sustainable food production. Manufacturers can produce high-quality products while minimizing their impact on the environment.

Choosing the Right Egg Powder Spray Dryer

Selecting the appropriate spray dryer is crucial for ensuring optimal performance and longevity in food processing operations.

Key Features to Look For

When choosing a spray dryer, several key features should be considered to ensure it meets production needs effectively.

- Efficiency: Opt for a spray dryer that offers efficient energy use, which will reduce operational costs and enhance sustainability.

- Capacity: Select a model that aligns with production volume requirements, ensuring it can handle the desired throughput.

- Ease of Maintenance: Choose equipment that is easy to clean and maintain, reducing downtime and extending the lifespan of the machinery.

Opciones de personalización

Many manufacturers offer customization options to tailor the equipment to specific production needs. Consider options that enhance the efficiency and effectiveness of the spray dryer in your operations.

Integration with Existing Systems

Ensure that the selected spray dryer can integrate seamlessly with existing production systems. This compatibility will streamline operations and maximize productivity.

Importance of Technological Support

Having access to technical support and training from the manufacturer can be invaluable. It ensures that operators are well-equipped to manage and maintain the equipment effectively.

Fabricantes y proveedores

There are numerous manufacturers and suppliers of egg powder spray dryers, each offering a range of models with unique features.

Evaluating Supplier Reputation

When selecting a supplier, evaluate their reputation in the industry. Consider factors such as product quality, customer service, and the reliability of their equipment.

Importance of Customer Service

Good customer service is crucial for ensuring a smooth purchasing process and ongoing support. Choose a supplier who provides comprehensive after-sales support and training.

After-Sales Support and Training

After-sales support and training are vital for maintaining the equipment’s performance. Ensure that the supplier offers robust support services to address any operational challenges.

Conclusión

Egg powder spray dryers are an essential tool in the food industry, offering numerous benefits such as enhanced shelf life, consistent product quality, and cost savings. Whether you are a large-scale manufacturer or a small producer, investing in spray drying technology can significantly improve production processes and contribute to sustainable practices.

Adopción de avances tecnológicos

By understanding the benefits and capabilities of egg powder spray dryers, food manufacturers can make informed decisions that enhance their operations and product offerings. Embracing this technology not only boosts efficiency and quality but also supports a more sustainable food production system.

Meeting the Growing Demand

As the demand for powdered egg products continues to grow, the role of spray dryers will become increasingly critical in meeting the needs of the modern food industry. Manufacturers who invest in this technology are well-positioned to capitalize on market opportunities.

Tendencias e innovaciones futuras

Looking ahead, continued advancements in spray drying technology will further enhance its benefits. Manufacturers can expect improvements in energy efficiency, product quality, and versatility, ensuring that spray drying remains a cornerstone of food processing innovation.

Presupuesto

|

especulación

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

capacidad de evaporación (kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

Cantidad de proceso de material líquido (kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

Producción de producto terminado (kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

contenido sólido del material líquido (%)

|

18-30

|

|||||||

|

contenido de humedad del producto terminado (%)

|

3-5

|

|||||||

|

potencia eléctrica (kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

fuente de calor

|

Vapor más electricidad

|

|||||||

|

Método de recolección del producto y su eficiencia

|

El removedor de polvo húmedo ciclónico de grado uno, dos o tres etapas es mayor o igual a 95%

|

|||||||

|

medidores e instrumentos de control automático

|

Indicador de temperatura del aire no aspirado y del aire de escape

|

|||||||

|

temperatura de entrada de aire (℃)

|

160-220

|

|||||||

|

temperatura de salida de aire (℃)

|

80-100

|

|||||||

|

Yo

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

dimensiones totales (mm)

|

O

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Aplicaciones

No se encontró ningún contenido que coincida con su selección.