Tabla de contenido

Detalle del producto

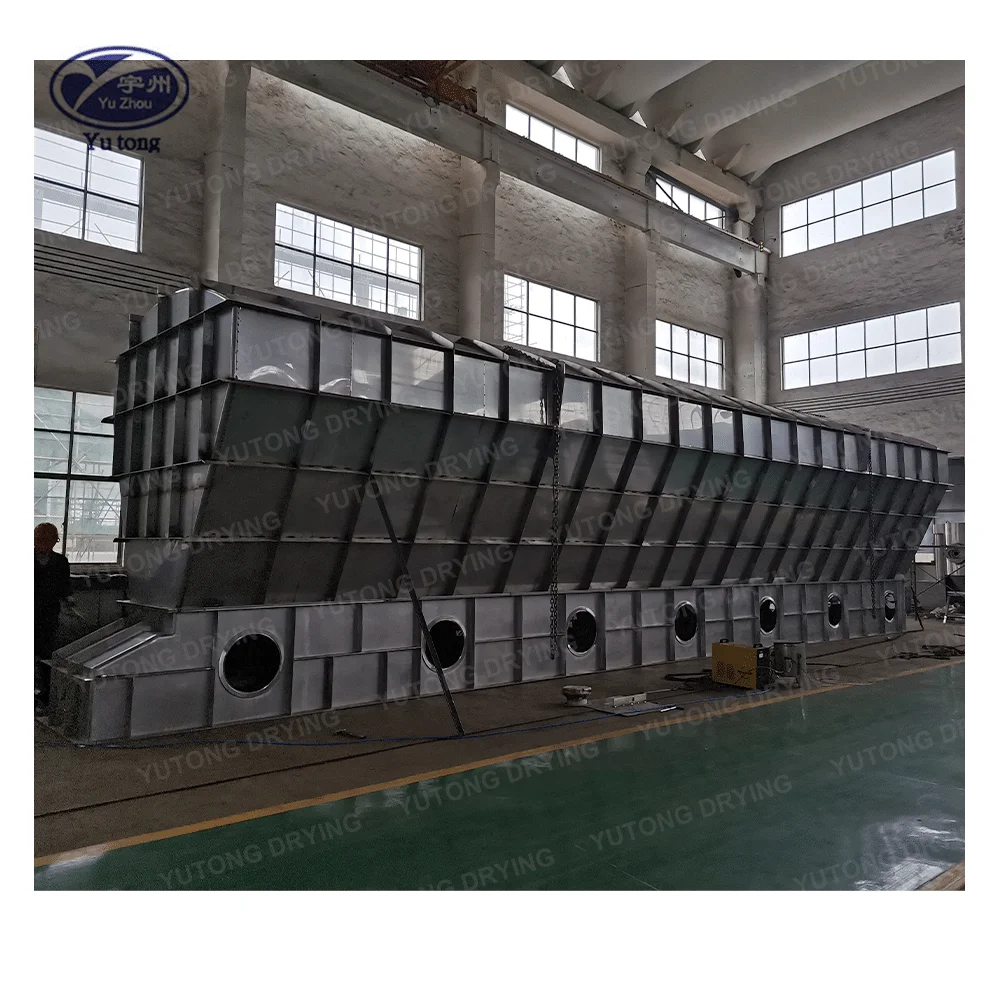

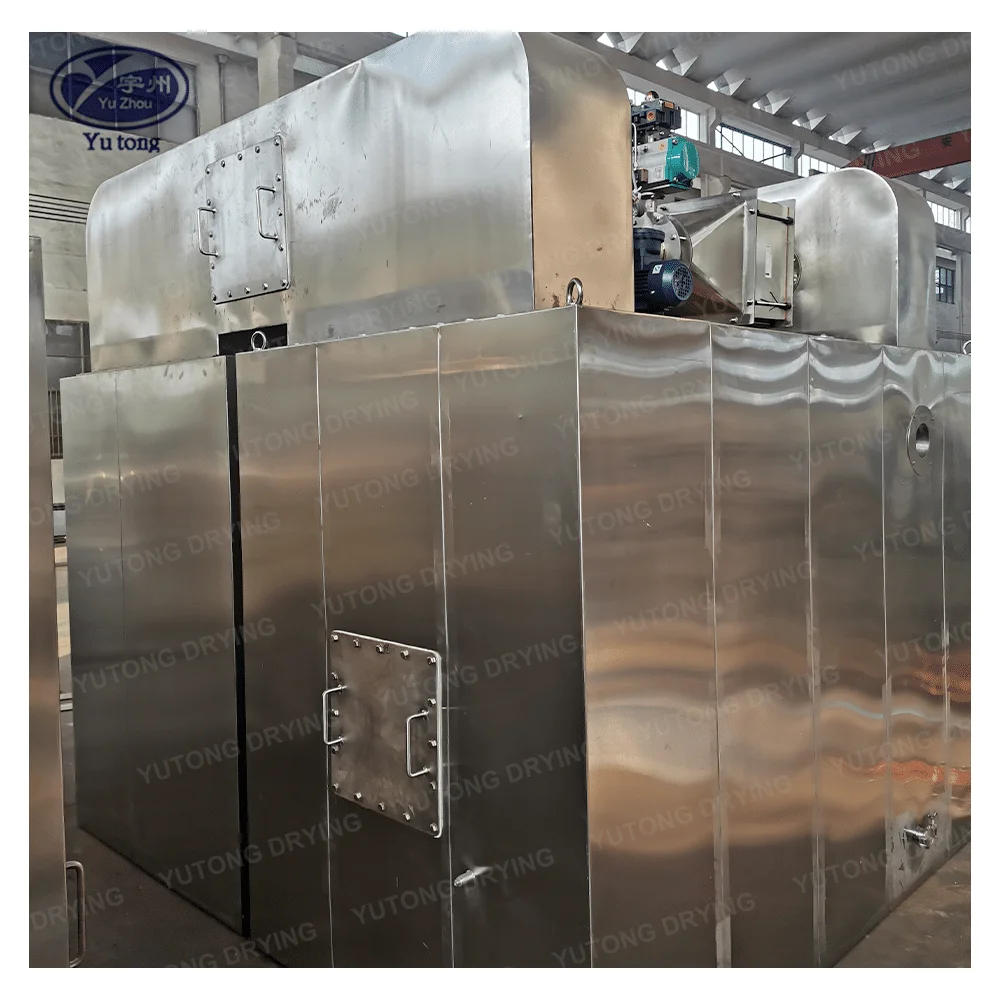

El secador de lecho fluidizado es una solución de secado altamente eficiente y versátil, ampliamente utilizada en diversas industrias. Es especialmente adecuado para el secado de polvos, gránulos y materiales cristalinos. El proceso de secado garantiza una distribución uniforme del calor y una mayor eficiencia térmica al suspender el material en una corriente de aire caliente, lo que mejora la transferencia de masa y calor.

Características principales:

- Alta eficiencia: Secado rápido con un consumo mínimo de energía debido a la distribución uniforme del aire y la fluidización.

- Calidad de producto constante: Mantiene el tamaño de partícula y el contenido de humedad uniformes.

- Multifuncional: Capaz de secar, enfriar, granular o recubrir en un solo proceso.

- Métodos de calentamiento flexibles: Compatible con sistemas de calefacción eléctricos o a vapor.

- Cumple con GMP: Diseño higiénico de fácil limpieza, adecuado para aplicaciones farmacéuticas y alimentarias.

- Operación segura: Equipado con sistemas de alivio de explosiones y telas filtrantes antiestáticas para garantizar la seguridad del operador.

Aplicaciones:

- Industria farmacéutica: Secado de gránulos húmedos y polvo para tabletas o cápsulas.

- Industria alimentaria: Procesamiento de productos como café, cacao, leche en polvo, saborizantes y especias.

- Industria química: Se utiliza para fertilizantes, pesticidas, pigmentos y resinas.

- Industria de piensos: Secado de alimentos y aditivos animales.

- Industria del plástico: Secado de gránulos plásticos y resinas termoplásticas.

| Tipo | Superficie de la cama (m³) | El secado | Potencia (Kw) | Presión del aire (Pa) | Volumen de aire (m³/H) | Toma de aire | Material | Consumo de energía de calefacción | Consumo de energía de calefacción Potencia eléctrica (kw) |

| capacidad | temperatura (℃) | descargar | Vapor (kg/h) | ||||||

| (agua Kg/h) | temperatura (℃) | ||||||||

| XF-10A | 0.25 | 5.5 | 4900 | 2300 | 60~140 | 40~80 | |||

| 10~15 | |||||||||

| 50 | 30 | ||||||||

| XF-10B | 0.25 | 4 | 3800 | 2300 | |||||

| XF-20A | 0.5 | 7.5 | 5000 | 3100 | |||||

| 20~25 | 100 | 60 | |||||||

| XF-20B | 0.5 | 5.5 | 3500 | 3100 | |||||

| XF-30A | 1 | 15 | 6000 | 4200 | |||||

| 30~45 | 150 | 90 | |||||||

| XF-30B | 1 | 11 | 4700 | 4200 | |||||

| XF-50A | 2 | 22 | 7400 | 6000 | |||||

| 50~80 | 250 | 150 | |||||||

| XF-50B | 2 | 18.5 | 5900 | 6000 |

Presupuesto

| Tipo | Superficie de la cama (m³) | El secado | Potencia (Kw) | Presión del aire (Pa) | Volumen de aire (m³/H) | Toma de aire | Material | Consumo de energía de calefacción | Consumo de energía de calefacción Potencia eléctrica (kw) |

| capacidad | temperatura (℃) | descargar | Vapor (kg/h) | ||||||

| (agua Kg/h) | temperatura (℃) | ||||||||

| XF-10A | 0.25 | 5.5 | 4900 | 2300 | 60~140 | 40~80 | |||

| 10~15 | |||||||||

| 50 | 30 | ||||||||

| XF-10B | 0.25 | 4 | 3800 | 2300 | |||||

| XF-20A | 0.5 | 7.5 | 5000 | 3100 | |||||

| 20~25 | 100 | 60 | |||||||

| XF-20B | 0.5 | 5.5 | 3500 | 3100 | |||||

| XF-30A | 1 | 15 | 6000 | 4200 | |||||

| 30~45 | 150 | 90 | |||||||

| XF-30B | 1 | 11 | 4700 | 4200 | |||||

| XF-50A | 2 | 22 | 7400 | 6000 | |||||

| 50~80 | 250 | 150 | |||||||

| XF-50B | 2 | 18.5 | 5900 | 6000 |

Aplicaciones

Productos farmacéuticos: secado de gránulos húmedos y polvo antes de la compresión de tabletas.

Industria alimentaria: Ideal para leche en polvo, gránulos de café, saborizantes y extractos de frutas.

Industria química: Eficaz para secar pigmentos, resinas y fertilizantes.

Agricultura: Secado de granos, semillas e ingredientes de alimentos para animales.