Tabla de contenido

Detalle del producto

Understanding the Basics of Fluid Bed Granulators

In the world of pharmaceuticals and chemical processing, granulation is a crucial process. It transforms fine powders into free-flowing granules, which are easier to handle, compress, and process. One piece of equipment that plays a pivotal role in this process is the fluid bed granulator. This article will delve into the basics of fluid bed granulators, exploring their functions, benefits, and applications.

A fluid bed granulator is a type of granulation equipment used primarily in the pharmaceutical industry but also finds use in the food and chemical industries. It combines powder granulation and drying in a single process, making it a highly efficient machine.

Fluid bed granulators are designed with specific features that enhance their functionality. These machines incorporate advanced technology to ensure precise control over the granulation process. For example, the integration of sophisticated control systems allows for real-time monitoring and adjustments, optimizing the granulation outcomes. Additionally, fluid bed granulators are built with durable materials to withstand the rigors of industrial processes, ensuring longevity and reliability.

In essence, a fluid bed granulator works by suspending solid particles in an upward-flowing stream of air. This creates a fluidized bed where the particles are mixed and coated with a granulation liquid. The result is a uniform distribution of the binder, leading to the formation of granules. This process not only enhances the flow properties of the powder but also ensures uniformity in the granule size, which is crucial for subsequent processing stages.

Compared to traditional granulation methods, fluid bed granulators offer several advantages. They provide a more efficient heat and mass transfer, resulting in faster drying times and better product quality. Moreover, the ability to conduct granulation and drying in a single unit reduces processing time and labor costs. This efficiency is particularly beneficial in industries where high throughput and product consistency are critical.

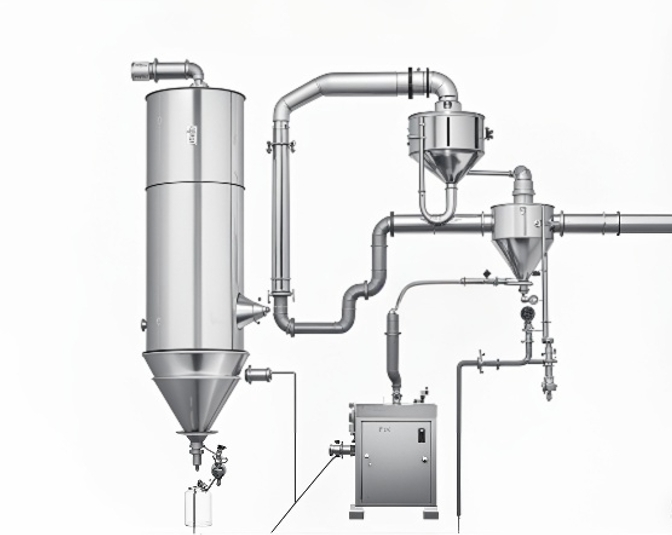

A typical fluid bed granulator consists of several key components:

- Air Handling Unit: This is responsible for supplying the air needed to fluidize the powder bed. The air handling unit includes fans, heaters, and filters that ensure the air is clean and at the right temperature and pressure for fluidization.

- Granulation Chamber: Here, the actual granulation process takes place. The chamber is designed to create optimal conditions for the fluidization of particles and the spraying of the binder solution.

- Filter System: It ensures that particles don’t escape into the environment. The filter system is crucial for maintaining a clean working environment and preventing product loss during the granulation process.

- Spray System: Used for spraying the granulation liquid onto the fluidized powder. The spray nozzles are strategically placed to ensure even distribution of the liquid, which is essential for uniform granule formation.

- Control System: Allows operators to manage and monitor the granulation process. The control system provides real-time data on temperature, air flow, and moisture content, enabling precise control over the granulation parameters.

Fluid bed granulation is a multistep process that efficiently transforms fine powders into uniform granules. Here’s a step-by-step breakdown:

1. Fluidization

The process begins with fluidization, where air is introduced into the granulation chamber. The air flows upward, lifting and suspending the powder particles in the air stream, creating a fluid-like state. This ensures even mixing and preparation for the next stages.

Optimizing Fluidization for Different Materials

Different materials require different fluidization conditions. For instance, powders with high moisture content may require higher air temperatures to achieve effective fluidization. Understanding the properties of the material being processed is essential for optimizing fluidization parameters.

2. Spraying

Once the powder is fluidized, a granulation liquid, often a binder, is sprayed onto the particles. The spray system ensures that the liquid is evenly distributed across the fluidized bed. This liquid binds the powder particles together, forming small granules.

Role of the Binder

The binder plays a crucial role in the granulation process. It acts as an adhesive, holding the powder particles together to form stable granules. The choice of binder and its concentration can significantly impact the properties of the final granules, such as their hardness and dissolution rate.

Spray Techniques

Different spray techniques can be employed depending on the desired granule characteristics. Top-spray, bottom-spray, and tangential-spray methods are commonly used, each offering distinct advantages in terms of liquid distribution and granule formation.

Ensuring Even Distribution

Achieving an even distribution of the granulation liquid is essential for uniform granule size and quality. Operators must ensure that the spray nozzles are properly aligned and functioning to prevent issues such as spray shadowing or over-wetting.

3. Drying

After the granules form, the drying phase begins. The continuous flow of air helps evaporate the liquid, drying the granules into a stable form. This step ensures that the granules have the desired moisture content and physical properties.

Techniques for Effective Drying

Various techniques can enhance the drying process, such as using heated air or incorporating microwave drying. These methods can improve drying efficiency and reduce the overall processing time.

Post-Drying Considerations

After drying, it’s essential to monitor the granules for any changes in physical properties. Quality control tests, such as moisture content analysis and hardness testing, ensure that the granules meet the required specifications.

4. Cooling

The final step involves cooling the dried granules to ambient temperature. This prevents any post-drying changes in the granules and stabilizes them for further processing.

Cooling Techniques

Different cooling techniques can be employed, such as using ambient air or chilled air. The choice of technique depends on factors like the granule composition and the desired cooling rate.

Ensuring Uniform Cooling

Uniform cooling is crucial to prevent issues like granule cracking or uneven moisture distribution. Proper airflow and equipment design play a significant role in achieving consistent cooling results.

Benefits of Using Fluid Bed Granulators

Fluid bed granulators offer several advantages over other granulation methods, making them a popular choice in various industries.

Efficient Granulation

Fluid bed processing allows for the simultaneous granulation and drying of materials. This dual functionality reduces processing time and increases overall efficiency.

Time and Cost Savings

By combining granulation and drying into a single step, fluid bed granulators reduce the need for additional equipment and labor. This results in significant time and cost savings, particularly in large-scale production environments.

Eficiencia energética

Fluid bed granulators are designed to optimize energy use. The efficient heat and mass transfer in the fluidized bed minimizes energy consumption, making these machines an environmentally friendly choice for granulation.

Escalabilidad

Fluid bed granulators offer scalability, making it easy to transition from pilot to full-scale production. The ability to adjust parameters like air flow and spray rate ensures consistent results across different batch sizes.

Consistent Product Performance

Uniform granule size and composition are crucial for consistent product performance. Whether in pharmaceuticals or food products, uniformity ensures that each batch meets the same high standards.

Enhanced Flow Properties

Uniform granules exhibit better flow properties, reducing issues such as segregation and caking during storage and handling. This improves the efficiency of downstream processes like tableting or encapsulation.

Control de calidad

The uniformity achieved with fluid bed granulators facilitates quality control, making it easier to detect and rectify any deviations from desired specifications.

Wide Range of Applications

From pharmaceuticals to chemicals and food products, fluid bed granulators can be used to process a variety of materials. This versatility makes them a valuable asset in diverse industries.

Adaptable to Formulation Changes

Fluid bed granulators can easily adapt to changes in formulations or product specifications. This flexibility is particularly beneficial in dynamic industries where product innovation is a key driver of success.

Customizable Features

Manufacturers can customize fluid bed granulators with features such as different spray systems or control options to meet specific processing requirements. This customization ensures optimal performance for each unique application.

Calidad del producto mejorada

The controlled environment within the granulator machine ensures that the final product meets stringent quality standards. The end granules are free-flowing, have the right moisture content, and are suitable for further processing.

Enhanced Stability

The controlled processing environment ensures that the granules are stable and retain their desired properties throughout their shelf life. This is particularly important for products that require a long storage period.

Consistent Batch Quality

Fluid bed granulators provide consistent batch quality, reducing the risk of batch-to-batch variations. This consistency is crucial for maintaining customer satisfaction and meeting regulatory requirements.

Cumplimiento de los estándares de la industria

Fluid bed granulators are designed to comply with industry standards and regulations, ensuring that the final products meet the necessary safety and quality benchmarks.

Applications of Fluid Bed Granulators

Industria farmacéutica

In the pharmaceutical sector, fluid bed granulators are instrumental in producing tablets and capsules. They ensure that active pharmaceutical ingredients (APIs) are evenly distributed within the granules, resulting in consistent dosage forms.

Consistent Dosage Forms

The even distribution of APIs in the granules ensures that each tablet or capsule contains the correct dosage. This consistency is vital for the efficacy and safety of pharmaceutical products.

Enhanced Bioavailability

Fluid bed granulation can improve the bioavailability of certain drugs by enhancing their dissolution rate. This is particularly important for poorly soluble drugs that require rapid absorption.

Cumplimiento de las normas regulatorias

Pharmaceutical manufacturers must comply with strict regulatory standards. Fluid bed granulators provide the precision and control needed to meet these standards and produce high-quality pharmaceutical products.

Industria alimentaria

In food processing, these granulators are used to create granular food products, such as instant soups or beverage powders. The process ensures that the granules dissolve quickly and evenly when reconstituted.

Quick and Even Dissolution

Granules produced by fluid bed granulation dissolve quickly and evenly, enhancing the convenience and quality of instant food products. This is a key selling point for consumers seeking quick meal solutions.

Preservando el valor nutricional

The gentle processing conditions in fluid bed granulators help preserve the nutritional value of food ingredients. This is important for maintaining the health benefits of processed food products.

Versatility in Food Applications

Fluid bed granulators can be used to process a wide range of food ingredients, from flavorings to nutritional supplements. This versatility makes them a valuable tool in the food industry.

Industria química

For the chemical industry, fluid bed granulators help in producing stable granules from fine powders. This is essential for products that require precise ingredient ratios and stability.

Stability and Homogeneity

Chemical products often require stable and homogeneous granules to ensure consistent performance. Fluid bed granulators provide the precision needed to achieve these characteristics.

Key Considerations When Choosing a Fluid Bed Granulator

When selecting a fluid bed granulator, several factors should be taken into account to ensure optimal performance and efficiency.

Tamaño y capacidad

The size of the granulator should match the production needs of your operation. Consider the batch size and frequency of production when determining the appropriate capacity.

Evaluación de las necesidades de producción

Before selecting a granulator, assess your production needs, including the type of products you manufacture and the required throughput. This assessment will help determine the appropriate size and capacity for your operation.

Balancing Flexibility and Efficiency

Choose a granulator that offers the right balance between flexibility and efficiency. A machine with adjustable parameters can adapt to varying production demands while maintaining optimal performance.

Cómo asegurar el futuro de su inversión

Consider future production growth when selecting a granulator. Investing in a machine with scalable capacity ensures that your equipment can accommodate increased production volumes as your business expands.

Compatibilidad de materiales

Ensure that the granulator is compatible with the materials you intend to process. Some materials may require specific types of binders or processing conditions.

Comprensión de las propiedades de los materiales

Different materials have unique properties that can affect the granulation process. Understanding these properties, such as particle size distribution and moisture content, is crucial for selecting the right granulator.

Binder and Additive Considerations

Some materials may require specific binders or additives to achieve the desired granule characteristics. Ensure that the granulator can accommodate these requirements to optimize the granulation process.

Pruebas y validación

Conducting tests and validation studies can help determine the compatibility of the granulator with your materials. This step ensures that the machine can consistently produce high-quality granules.

Control Systems

Advanced control systems allow for precise monitoring and adjustment of the granulation process. This is crucial for maintaining product quality and consistency.

Importance of Real-Time Monitoring

Real-time monitoring of process parameters such as temperature, air flow, and moisture content is essential for maintaining consistent product quality. Advanced control systems provide the data needed to make informed adjustments during production.

Automatización y eficiencia

Automation features in control systems can enhance efficiency by reducing the need for manual intervention. This allows operators to focus on other critical tasks, improving overall productivity.

Customizable Control Options

Look for granulators with customizable control options that can be tailored to your specific process requirements. This flexibility ensures optimal performance and quality control.

Maintenance and Cleaning

Consider the ease of maintenance and cleaning when selecting a granulator. A machine that is easy to clean and maintain will reduce downtime and improve overall efficiency.

Designing for Easy Maintenance

Choose a granulator with a design that facilitates easy access to components for maintenance and cleaning. This reduces downtime and minimizes the risk of contamination.

Implementing a Maintenance Schedule

Establish a regular maintenance schedule to keep the granulator in optimal working condition. Routine inspections and preventive maintenance can help identify and address potential issues before they impact production.

Ensuring Hygienic Design

For industries with strict hygiene requirements, such as pharmaceuticals and food processing, select a granulator with a hygienic design. This ensures that the equipment meets the necessary sanitation standards.

Conclusión

Fluid bed granulators are essential tools in the granulation process, offering efficiency, versatility, and consistent product quality. Whether in pharmaceuticals, food processing, or chemical manufacturing, these machines streamline operations and enhance the quality of the final product. By understanding the basics of fluid bed granulators, you can make informed decisions about integrating this technology into your production process, ensuring optimal results and efficiency. Investing in a fluid bed granulator not only improves productivity but also ensures compliance with industry standards, making it a valuable addition to any production facility.

Presupuesto

No se encontró ningún contenido que coincida con su selección.

Aplicaciones

No se encontró ningún contenido que coincida con su selección.