Tabla de contenido

Detalle del producto

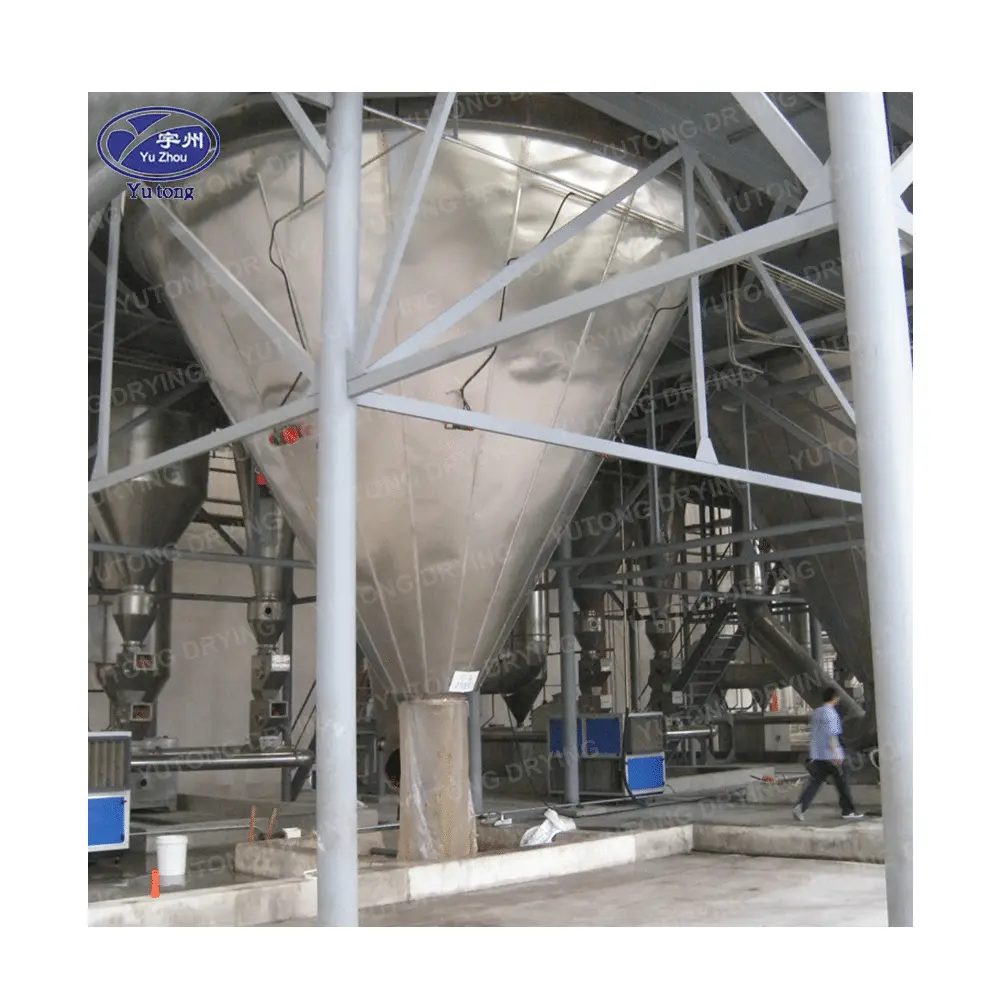

Uno de los pasos más cruciales para preparar café instantáneo es el proceso de secado. Aquí es donde ocurre la magia: el extracto líquido de café se transforma en los gránulos solubles que conocemos como café instantáneo. Un método popular en la industria es el secado por aspersión. Profundicemos en el proceso de secado por aspersión y entendamos cómo transforma tu café matutino.

Entendiendo el secado por aspersión

El secado por aspersión es un método para producir un polvo seco a partir de un líquido mediante su secado rápido con gas caliente. Esta técnica se utiliza comúnmente en la industria alimentaria, especialmente para la elaboración de alimentos y bebidas en polvo, como el café instantáneo.

La ciencia detrás del secado por aspersión

En términos sencillos, el secado por aspersión consiste en rociar el extracto líquido de café en una cámara llena de aire caliente. El calor evapora el líquido, dejando partículas de café secas. Estas partículas se recogen para formar café instantáneo.

Este proceso es eficiente y permite producir grandes cantidades de café en polvo rápidamente. El aire caliente utilizado en el secado por aspersión suele estar entre 150 °C y 300 °C, lo que garantiza que el agua del extracto de café se evapore casi instantáneamente, preservando así su sabor y aroma.

Además, el diseño de la cámara de secado por aspersión es crucial. Garantiza que las gotas tengan suficiente tiempo en el aire para perder completamente su humedad. Este aspecto es vital para conservar la esencia del café y lograr la sequedad deseada.

Pasos para el secado por aspersión del café

- Preparación del extracto de café: El proceso comienza con la infusión de los granos de café para crear un extracto fuerte, generalmente más concentrado que el café convencional. La elección de los granos y el método de preparación influyen considerablemente en el sabor resultante del café instantáneo.

- Atomización: El café líquido se introduce en un secador por aspersión, donde se atomiza en una fina capa de gotitas mediante un atomizador o una boquilla. El tamaño de estas gotitas se puede controlar para influir en la textura y la solubilidad del producto final.

- Secado: Las gotas se introducen en una cámara de secado llena de aire caliente. Al entrar en contacto con el aire caliente, se secan casi instantáneamente, formando finas partículas de café. La velocidad y la temperatura del aire se pueden ajustar para optimizar el proceso de secado y garantizar la calidad.

- Recolección: Las partículas de café seco se recogen del fondo de la cámara de secado. Posteriormente, se enfrían y, en ocasiones, se aglomeran para mejorar su solubilidad en agua. La aglomeración ayuda a crear partículas más grandes que se disuelven más fácilmente en agua, mejorando así la experiencia del consumidor.

- Empaquetado: Finalmente, el café instantáneo se envasa y está listo para su distribución. El empaquetado es fundamental para preservar la frescura y la calidad del café hasta su llegada al consumidor.

Secado por aspersión vs. liofilización

Si bien el secado por aspersión es un método popular, la liofilización es otra técnica utilizada para producir café instantáneo. Cada método tiene ventajas y desventajas que afectan el sabor, la textura y el costo del producto final.

Sabor y aroma

El secado por aspersión suele ser más rentable, pero a veces puede resultar en una ligera pérdida de sabor y aroma en comparación con la liofilización. Las altas temperaturas utilizadas en el secado por aspersión pueden provocar cierta degradación de los delicados compuestos del café. Sin embargo, los avances tecnológicos han ayudado a mitigar estos efectos, garantizando que el café secado por aspersión conserve un sabor agradable.

A pesar de los desafíos, innovaciones como el control de temperatura y los tiempos de procesamiento rápidos ayudan a conservar gran parte del aroma natural del café. La industria continúa explorando nuevas maneras de minimizar la pérdida de sabor durante el proceso de secado por aspersión.

La liofilización, por otro lado, es conocida por preservar mejor el aroma y el sabor del café. Este método consiste en congelar el extracto de café y luego sublimar el hielo a baja presión. Como resultado, el café liofilizado suele tener un sabor y un aroma más intensos.

Las temperaturas más bajas que se utilizan en la liofilización previenen la degradación térmica de los compuestos aromáticos, lo que la convierte en la opción preferida para productos de café premium. Sin embargo, este método tiene un costo mayor, lo cual puede afectar el precio de mercado del producto.

Textura y solubilidad

Gracias a su fino tamaño de partícula, el café atomizado suele ser más soluble en agua, lo que facilita y agiliza su preparación. El proceso también se puede ajustar para producir diferentes texturas, desde polvos finos hasta gránulos más gruesos.

Esta adaptabilidad permite a los fabricantes adaptar sus productos a las preferencias del consumidor, ofreciendo una gama de experiencias de café instantáneo. La solubilidad del café en polvo lo hace ideal para consumidores ocupados que buscan una dosis rápida de cafeína.

Si bien el café liofilizado, un poco menos soluble, tiende a tener una textura visualmente más atractiva, los gránulos más grandes pueden darle al producto una sensación más premium, que algunos consumidores prefieren.

La textura distintiva del café liofilizado a menudo se percibe como una marca de calidad, y atrae a los entusiastas del café que priorizan el sabor y la presentación por sobre la conveniencia.

Costo y eficiencia

El secado por aspersión suele ser más rentable y eficiente que la liofilización. Permite producir grandes volúmenes de café instantáneo en un tiempo relativamente corto, lo que lo convierte en una opción atractiva para los fabricantes.

Esta eficiencia se traduce en menores costos de producción, lo que permite a las empresas ofrecer productos a precios competitivos sin comprometer la calidad. La escalabilidad del secado por aspersión lo hace ideal para satisfacer la alta demanda de los consumidores.

Si bien la liofilización ofrece una calidad superior en algunos aspectos, también es un proceso más largo y costoso. Esto puede resultar en precios más altos para los productos de café liofilizado.

A pesar de su mayor costo, la liofilización sigue siendo una opción popular para las marcas de café especial que buscan ofrecer la mejor experiencia de sabor posible a sus consumidores.

El papel de los secadores por aspersión en la producción de café instantáneo

Los secadores por aspersión son cruciales en la producción de café instantáneo. Su capacidad para transformar rápida y eficientemente el extracto de café líquido en un polvo estable y soluble los hace indispensables en la industria.

Ventajas de los secadores por aspersión

- Eficiencia: Los secadores por aspersión pueden procesar grandes cantidades de extracto de café rápidamente, lo que los hace ideales para la producción de gran volumen.

El rápido tiempo de procesamiento permite a los fabricantes mantenerse al día con la alta demanda de los consumidores de café instantáneo, especialmente en mercados donde la conveniencia es muy valorada.

- Rentabilidad: El proceso generalmente es menos costoso que la liofilización, lo que lo convierte en una opción popular para muchos fabricantes.

Esta ventaja de costos permite a las empresas invertir en otras áreas, como marketing y desarrollo de productos, para mejorar la ventaja competitiva de su marca.

- Versatilidad: El secado por aspersión puede producir una variedad de productos de café con diferentes texturas y niveles de solubilidad.

Esta versatilidad permite a los fabricantes satisfacer diversas preferencias de los consumidores, ofreciendo una amplia gama de opciones de café instantáneo en el mercado.

Desafíos de los secadores por aspersión

- Sensibilidad al calor: Las altas temperaturas utilizadas en el secado por aspersión a veces pueden provocar que el producto final pierda sabor y aroma.

Para abordar este desafío es necesario un control cuidadoso de las condiciones de secado y una investigación continua para perfeccionar el proceso y minimizar la pérdida de sabor.

- Control del tamaño de partículas: garantizar un tamaño de partículas constante puede ser un desafío, ya que requiere un control preciso de las condiciones de secado.

Mantener la uniformidad en el tamaño de las partículas es crucial para lograr una solubilidad constante y la satisfacción del consumidor en diferentes lotes de café instantáneo.

Innovaciones en la tecnología de secado por aspersión

Los avances en la tecnología de secado por aspersión siguen mejorando la calidad y la eficiencia de la producción de café instantáneo. Se están desarrollando nuevas técnicas y equipos para preservar mejor el sabor y el aroma del café, a la vez que mejoran su solubilidad y textura.

Técnicas de atomización mejoradas

Los secadores por aspersión modernos utilizan técnicas de atomización avanzadas para crear tamaños de gotas más uniformes, lo que produce un secado más consistente y productos de mejor calidad.

Estas técnicas ayudan a lograr un tamaño de partícula más uniforme, lo que mejora la solubilidad y la consistencia del producto final y cumple con las expectativas de calidad del consumidor.

Sistemas de control mejorados

Los sistemas de control de última generación permiten una gestión precisa de las condiciones de secado, reduciendo el riesgo de pérdida de sabor y garantizando un producto final de alta calidad.

Los sensores avanzados y las tecnologías de automatización permiten el monitoreo y los ajustes en tiempo real durante el proceso de secado, garantizando que se mantengan condiciones óptimas en todo momento.

Eficiencia energética

Los secadores por aspersión más nuevos están diseñados para ser más eficientes energéticamente, reduciendo el impacto ambiental de la producción de café instantáneo y bajando los costos operativos.

La atención a la eficiencia energética beneficia al medio ambiente y ayuda a los fabricantes a reducir costes, que pueden trasladarse a los consumidores en forma de productos más asequibles.

Conclusión

El proceso de secado por aspersión de café es un componente crucial en la producción de café instantáneo, ofreciendo una forma rentable y eficiente de producir café en polvo de alta calidad. Si bien este método presenta desafíos, las innovaciones tecnológicas constantes siguen mejorando la calidad y la sostenibilidad del café secado por aspersión.

Tanto si eres un entusiasta del café como si eres fabricante, comprender las complejidades del proceso de secado por aspersión puede ayudarte a apreciar la artesanía detrás de cada taza de café instantáneo. A medida que la tecnología avanza, podemos esperar productos de café instantáneo con un sabor aún mejor y más sostenibles en el futuro.

La continua evolución de la tecnología de secado por aspersión promete posibilidades interesantes para la industria del café instantáneo, allanando el camino para nuevos sabores, mejor calidad y mayor sostenibilidad en los próximos años.

Presupuesto

|

especulación

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

capacidad de evaporación (kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

Cantidad de proceso de material líquido (kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

Producción de producto terminado (kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

contenido sólido del material líquido (%)

|

18-30

|

|||||||

|

contenido de humedad del producto terminado (%)

|

3-5

|

|||||||

|

potencia eléctrica (kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

fuente de calor

|

Vapor más electricidad

|

|||||||

|

Método de recolección del producto y su eficiencia

|

El removedor de polvo húmedo ciclónico de grado uno, dos o tres etapas es mayor o igual a 95%

|

|||||||

|

medidores e instrumentos de control automático

|

Indicador de temperatura del aire no aspirado y del aire de escape

|

|||||||

|

temperatura de entrada de aire (℃)

|

160-220

|

|||||||

|

temperatura de salida de aire (℃)

|

80-100

|

|||||||

|

Yo

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

dimensiones totales (mm)

|

O

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Aplicaciones

No se encontró ningún contenido que coincida con su selección.