Fluid bed dryers operate on a simple yet effective principle. They use a process where hot gas is passed through a perforated distributor to fluidize solid particles. This fluidization causes the particles to behave like a fluid, allowing for uniform drying. The hot gas helps to remove moisture from the particles, resulting in a thoroughly dried product.

What is a Fluid Bed Dryer?

A fluid bed dryer is a type of equipment used to efficiently dry particulate materials. It is widely used in industries such as pharmaceuticals, chemicals, food processing, and more. The equipment can handle a variety of materials, including powders, granules, and small particles.

In the pharmaceutical industry, fluid bed dryers are crucial for drying active ingredients and excipients, ensuring they achieve the desired moisture content without degradation. The chemical industry utilizes these dryers to process a wide range of compounds, including heat-sensitive materials that require gentle drying. In the food sector, fluid bed dryers help maintain the nutritional value of food ingredients while effectively removing moisture.

How Does a Fluid Bed Dryer Work?

The working principle of a fluid bed dryer involves passing hot air or gas through a bed of solid particles. This creates a fluidized state where the particles are suspended and move freely. The contact between the hot gas and the particles results in rapid and uniform drying.

The fluidization process is enhanced by the careful design of the dryer, which includes a perforated plate that ensures even distribution of gas flow. As the hot air rises through the bed of particles, it lifts them, creating a fluid-like motion that maximizes surface contact. This movement increases heat transfer efficiency, reducing drying time significantly.

Moreover, the adjustable parameters of a fluid bed dryer, such as air temperature, velocity, and humidity, allow for precise control over the drying process. This control is essential for achieving consistent product quality, especially in industries where moisture content is critical to product performance.

Key Components of Fluid Bed Dryers

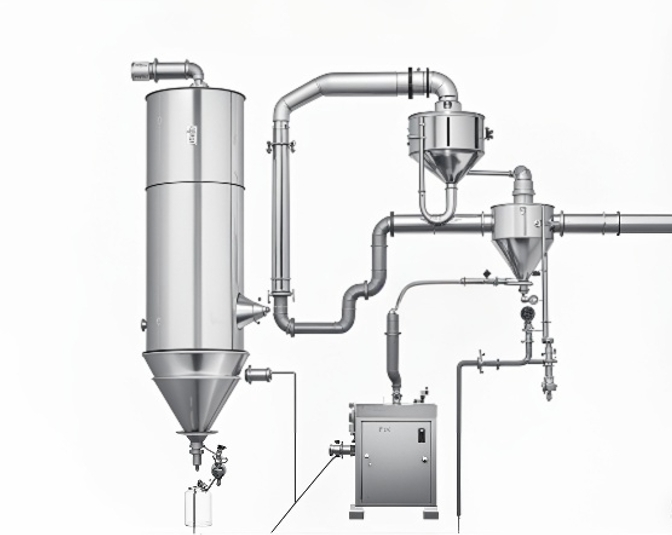

Fluid bed dryers consist of several key components, each playing a vital role in the drying process. The air handling system is responsible for heating and distributing the air or gas that fluidizes the particles. The drying chamber, often equipped with a perforated plate, ensures even fluidization and optimal heat transfer.

Additionally, fluid bed dryers may include a dust collection system to capture fine particles and prevent them from escaping into the environment. The control system is another critical component, enabling operators to monitor and adjust drying parameters in real-time. These components work together to deliver a highly efficient and controlled drying process.

Advantages of Fluid Bed Dryers

Fluid bed dryers offer several advantages over traditional drying methods. These advantages make them a popular choice across industries for various drying applications.

Efficient Drying Process

Fluid bed dryers provide a highly efficient drying process. The fluidization of particles ensures even heat distribution, leading to uniform drying. This efficiency reduces drying time and energy consumption, making it a cost-effective option.

The rapid heat transfer in fluid bed dryers minimizes the time required to achieve the desired moisture content, increasing throughput and productivity. Moreover, the uniform drying prevents the formation of hotspots, which can cause product degradation or uneven drying. This efficiency translates to lower operational costs, as less energy is required to achieve optimal drying conditions.

Furthermore, the fluid bed drying process is scalable, allowing industries to increase production without compromising efficiency. By optimizing drying parameters, manufacturers can achieve significant energy savings, contributing to sustainable production practices.

Versatility

Fluid bed dryers are versatile and can handle a wide range of materials, including heat-sensitive products. They are suitable for drying powders, granules, and small particles, making them adaptable to different industrial needs.

The ability to process various materials is a significant advantage, as it allows industries to use a single dryer for multiple products. This versatility reduces the need for multiple drying systems, saving space and investment costs. Fluid bed dryers can also be equipped with specialized features, such as cooling sections or agglomeration capabilities, to enhance their adaptability further.

In industries where product specifications vary, the flexibility of fluid bed dryers ensures that diverse materials can be processed efficiently and effectively. This adaptability is particularly beneficial for contract manufacturers who handle different products for various clients.

Improved Product Quality

The gentle drying process in fluid bed dryers helps maintain the integrity of the product. It minimizes the risk of degradation or damage, ensuring high-quality output. This is especially important in industries such as pharmaceuticals and food processing.

The even heat distribution and controlled drying environment prevent thermal degradation, preserving the chemical and physical properties of sensitive materials. In the pharmaceutical industry, this is crucial for maintaining the efficacy of active ingredients. For food products, fluid bed drying helps retain essential nutrients, flavors, and textures, ensuring consumer satisfaction.

Additionally, fluid bed dryers offer options for controlling particle size distribution, which can enhance product quality and performance. By adjusting fluidization parameters, manufacturers can achieve the desired granule size and uniformity, meeting specific product requirements.

Scalability

Fluid bed dryers are available in various sizes and configurations, allowing for easy scalability. Whether you need a lab-scale fluid bed dryer for research or a large-scale industrial system, there is a suitable option available.

The scalability of fluid bed dryers is advantageous for companies planning to expand production capacity. By selecting the appropriate size and configuration, businesses can seamlessly transition from pilot-scale operations to full-scale production. This flexibility ensures that fluid bed dryers can accommodate growing demand without the need for significant equipment modifications.

Moreover, the modular design of some fluid bed dryers allows for easy integration with existing systems, reducing installation time and costs. This scalability ensures that companies can adapt to market changes and production needs efficiently.

Types of Fluid Bed Dryer

Fluid bed dryers come in different types, each designed to meet specific drying requirements. Let’s explore some common types of fluid bed dryers.

Vibrating Fluid Bed Dryer

A vibrating fluid bed dryer uses vibration to enhance the fluidization process. This type of dryer is suitable for materials that are difficult to fluidize or require additional agitation for efficient drying.

The addition of vibration aids in breaking up agglomerates and improving particle movement, resulting in more uniform drying. This feature is particularly beneficial for sticky or cohesive materials that might clump together during the drying process. By preventing clumping, vibrating fluid bed dryers ensure a consistent drying environment, enhancing product quality.

Moreover, the adjustable vibration intensity allows operators to customize the drying process for different materials, optimizing efficiency and product output. The combination of vibration and fluidization makes this type of dryer a versatile option for challenging drying applications.

Continuous Fluid Bed Dryer

Continuous fluid bed dryers are designed for continuous operation, making them ideal for high-volume production. They offer a continuous flow of material through the drying chamber, ensuring a consistent drying process.

The continuous design eliminates downtime between batches, increasing throughput and production efficiency. This design is particularly beneficial for industries with high production demands, such as food processing and chemicals. Continuous fluid bed dryers also feature automated controls that maintain consistent drying conditions, ensuring product uniformity.

In addition, the continuous operation allows for integration with upstream and downstream processes, streamlining production lines and reducing handling time. This seamless integration enhances overall operational efficiency and reduces labor costs.

Customized Fluid Bed Dryer

Customized fluid bed dryers are tailored to meet specific industry requirements. Manufacturers can design these dryers with specific features, such as programmable controls or under isolator designs, to suit unique processing needs.

Customization allows industries to address specific challenges or requirements, such as handling hazardous materials or meeting stringent regulatory standards. By incorporating specialized features, such as inert gas environments or precise temperature control, customized fluid bed dryers can optimize drying conditions for sensitive materials.

Furthermore, customization options extend to the physical design of the dryer, allowing it to fit into existing production layouts or meet space constraints. This flexibility ensures that fluid bed dryers can be adapted to a wide range of industrial settings, enhancing their applicability.

Applications of Fluid Bed Dryer

Fluid bed dryers find applications in a wide range of industries due to their versatility and efficiency. Here are some common applications:

Pharmaceutical Industry

In the pharmaceutical industry, fluid bed dryers are used for drying powders and granules. They ensure precise control over drying parameters, resulting in high-quality pharmaceutical products.

The precise control over temperature and humidity levels helps maintain the stability and efficacy of active pharmaceutical ingredients (APIs). Additionally, fluid bed dryers can be used for granulation processes, where they not only dry but also help form uniform granules. This dual functionality streamlines production and enhances product consistency.

Moreover, the gentle drying process minimizes the risk of contamination, maintaining the purity of pharmaceutical products. This is essential in an industry where quality and safety standards are paramount.

Food Processing

Fluid bed dryers are widely used in the food processing industry for drying food ingredients and products. They help maintain the nutritional value and quality of food while ensuring efficient moisture removal.

In food processing, fluid bed dryers are used to dry a variety of products, from cereals and grains to fruits and vegetables. The even heat distribution prevents scorching and preserves flavors and nutrients, enhancing the quality of the final product. Additionally, the ability to control drying parameters allows manufacturers to tailor the process to specific product requirements.

The energy efficiency of fluid bed dryers also contributes to cost savings, making them an attractive option for food producers. By reducing drying time and energy consumption, fluid bed dryers support sustainable production practices in the food industry.

Chemical Industry

In the chemical industry, fluid bed dryers are used for drying chemicals and intermediates. They provide a controlled drying environment, ensuring consistent product quality.

The ability to handle a wide range of chemical compounds, including heat-sensitive and volatile substances, makes fluid bed dryers a versatile choice for chemical manufacturers. The controlled drying environment minimizes the risk of degradation, preserving the properties of chemical products. Additionally, fluid bed dryers can be used for coating and agglomeration processes, enhancing product functionality.

Furthermore, the scalability and customization options of fluid bed dryers allow chemical manufacturers to adapt to changing production needs and regulatory requirements. This flexibility ensures that fluid bed dryers can meet the diverse demands of the chemical industry.

Other Industries

Fluid bed dryers are also used in industries such as agriculture, minerals, and more. Their adaptability and efficiency make them suitable for diverse drying applications.

In the agricultural sector, fluid bed dryers are used to process seeds and grains, enhancing their shelf life and quality. For mineral processing, fluid bed dryers efficiently remove moisture from ores and concentrates, improving handling and storage. The versatility of fluid bed dryers ensures they can be applied to a wide range of materials and industries, making them a valuable asset in various production environments.

Additionally, the ability to integrate fluid bed dryers with other processing equipment enhances their applicability in complex production lines. This integration supports efficient and streamlined operations across industries.

Considerations When Choosing a Fluid Bed Dryer

When selecting a fluid bed dryer for your industrial drying needs, there are several important considerations to keep in mind.

Material Compatibility

Ensure that the fluid bed dryer is compatible with the materials you need to dry. Consider factors such as particle size, moisture content, and sensitivity to heat.

Material compatibility is crucial for achieving optimal drying results. Assessing the properties of the materials, such as their thermal stability and hygroscopic nature, helps determine the most suitable drying parameters. Additionally, considering the physical characteristics of the materials, such as shape and density, ensures that the fluid bed dryer can effectively handle them without causing damage or inefficiencies.

Furthermore, understanding the chemical composition of the materials is essential for preventing adverse reactions during the drying process. This knowledge helps in selecting the appropriate materials for constructing the dryer, ensuring durability and safety.

System Design

Evaluate the design and features of the fluid bed dryer system. Consider aspects such as control systems, energy efficiency, and ease of maintenance.

The design of the fluid bed dryer system influences its performance and operational efficiency. Modern control systems offer advanced features, such as real-time monitoring and automated adjustments, enhancing precision and consistency. Energy-efficient designs reduce operational costs and support sustainable practices, making them a preferred choice for environmentally conscious industries.

Ease of maintenance is another critical factor, as it impacts downtime and overall productivity. Choosing a fluid bed dryer with accessible components and straightforward maintenance procedures ensures long-term reliability and cost savings.

Cost and Budget

Consider the cost of the fluid bed dryer and your budget constraints. While fluid bed dryers offer long-term cost savings, it’s important to evaluate the initial investment and operational costs.

Assessing the total cost of ownership, including installation, operation, and maintenance expenses, helps determine the financial feasibility of investing in a fluid bed dryer. Although the initial investment may be higher compared to traditional drying methods, the efficiency and versatility of fluid bed dryers often result in lower operational costs over time.

Moreover, considering potential energy savings and increased productivity can justify the investment, as these benefits contribute to improved profitability. Evaluating the return on investment helps make an informed decision that aligns with your budget and production goals.

Manufacturer Reputation

Choose a reputable manufacturer with a proven track record in producing high-quality fluid bed dryers. Research customer reviews and testimonials to ensure reliability and performance.

A manufacturer’s reputation reflects their commitment to quality and customer satisfaction. By selecting a reputable manufacturer, you can trust that the fluid bed dryer will meet industry standards and deliver consistent performance. Customer reviews and testimonials provide valuable insights into the manufacturer’s reliability, after-sales service, and overall product quality.

Additionally, working with an experienced manufacturer ensures access to expert guidance and support, from equipment selection to installation and maintenance. This partnership enhances the success of your drying operations and contributes to a positive overall experience.

Conclusion

Fluid bed dryers offer numerous advantages, making them a preferred choice for industrial drying applications. Their efficient drying process, versatility, and improved product quality set them apart from traditional methods. By understanding the various types and applications of fluid bed dryers, you can make an informed decision when choosing the right equipment for your industrial drying needs.

Investing in a fluid bed dryer can enhance your production efficiency, reduce energy consumption, and improve product quality. Whether you’re in the pharmaceutical, food processing, or chemical industry, fluid bed dryers provide a reliable and effective solution for your drying requirements.

The decision to invest in a fluid bed dryer represents a commitment to innovation and efficiency. As industries continue to evolve, embracing advanced drying technologies like fluid bed dryers positions businesses for success in an increasingly competitive market. By prioritizing quality and efficiency, fluid bed dryers contribute to sustainable and profitable operations across diverse industries.