Table des matières

Détails du produit

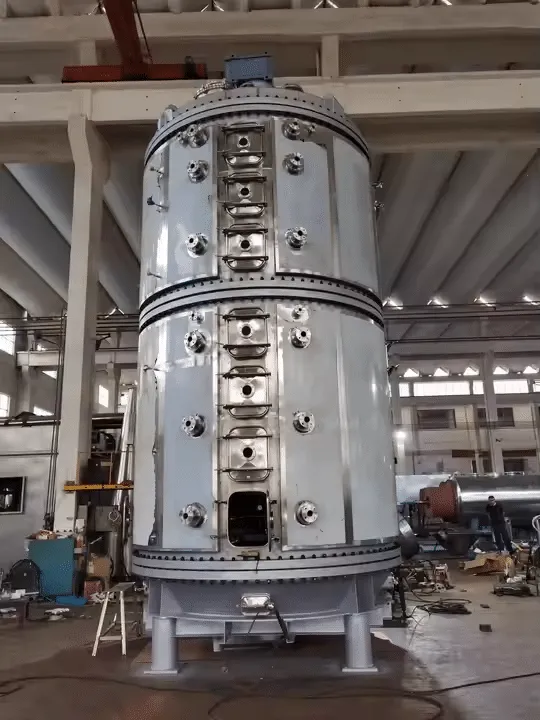

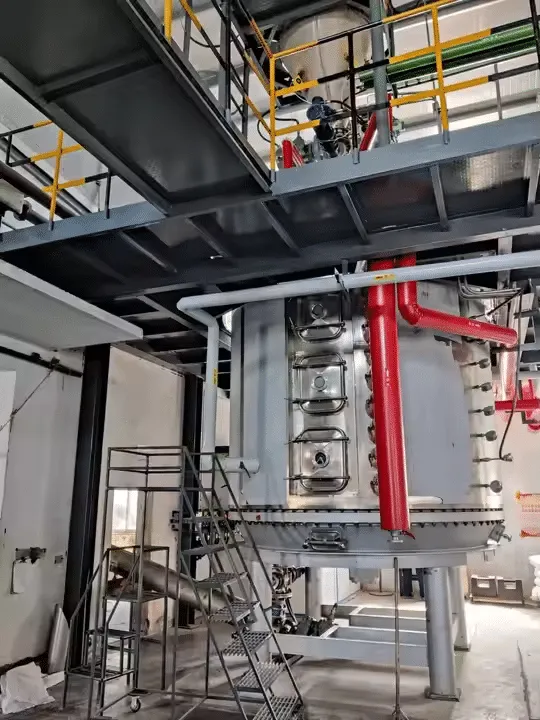

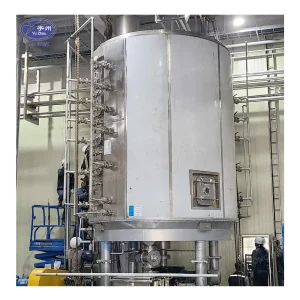

Le sécheur sous vide pour procédés chimiques est une solution de séchage spécialisée conçue pour répondre aux exigences rigoureuses des environnements de production chimique. Conçu pour éliminer l'humidité des composés sensibles, thermosensibles ou volatils de manière sûre et efficace, ce sécheur joue un rôle essentiel dans l'optimisation des procédés.

Caractéristiques principales :

-

Technologie de séchage sous vide : Permet un séchage à basse température pour éviter la décomposition ou l'oxydation de produits chimiques réactifs ou sensibles à la chaleur.

-

Haute efficacité : Accélère les cycles de séchage grâce à un transfert de chaleur et de masse optimisé dans des conditions de vide.

-

Conception antidéflagrante et résistante à la corrosion : Fabriqué en acier inoxydable de qualité chimique et avec des composants antidéflagrants en option pour la manipulation de substances dangereuses.

-

Système de contrôle précis : Interface de contrôle avancée pour régler la température, le niveau de vide et le temps de séchage avec une grande précision.

-

Conception évolutive : Disponible en capacités de laboratoire, pilotes et de production complète pour répondre aux différents besoins des processus chimiques.

-

Fonctionnement en système fermé : Minimise les pertes de solvant, protège les opérateurs et maintient un environnement de production propre.

Caractéristiques

| Caractéristiques | Diamètre extérieur (mm) | Hauteur (mm) | Surface de séchage (m2) | Puissance (kW) |

| 1200/4 | 1850 | 2608 | 3.3 | 1.1 |

| 1200/6 | 3028 | 4.9 | ||

| 1200/8 | 3448 | 6.6 | 1.5 | |

| 1200/10 | 3868 | 8.2 | ||

| 1200/12 | 4288 | 9.9 | ||

| 1500/6 | 2100 | 3022 | 8 | 2.2 |

| 1500/8 | 3442 | 10.7 | ||

| 1500/10 | 3862 | 13.4 | ||

| 1500/12 | 4282 | 16.1 | 3 | |

| 1500/14 | 4702 | 18.8 | ||

| 1500/16 | 5122 | 21.5 | ||

| Juin-00 | 2900 | 3262 | 18.5 | 3 |

| Août-00 | 3682 | 24.6 | ||

| Oct-00 | 4102 | 30.8 | ||

| Déc-00 | 4522 | 36.9 | 4 | |

| 2200/14 | 4942 | 43.1 | 5 | |

| 2200/16 | 5362 | 49.3 | ||

| Août-00 | 2900 | 5782 | 55.4 | 5.5 |

| 2200/20 | 6202 | 61.6 | ||

| 2200/22 | 6622 | 67.6 | 7.5 | |

| 2200/24 | 7042 | 73.9 | ||

| 2200/26 | 7462 | 80 | ||

| Août-00 | 3800 | 4050 | 48 | 11 |

| Oct-00 | 4650 | 60 | ||

| Déc-00 | 5250 | 72 | ||

| 3000/14 | 5850 | 84 | ||

| 3000/16 | 6450 | 96 | ||

| 3000/18 | 7050 | 108 | 13 | |

| 3000/20 | 7650 | 120 | ||

| 3000/22 | 8250 | 132 | ||

| 3000/24 | 8850 | 144 | ||

| 3000/26 | 9450 | 156 | 15 | |

| 3000/28 | 10050 | 168 | ||

| 3000/30 | 10650 | 180 |

Applications

Le sécheur à plaques continu PLG est adapté au séchage, à la calcination, à la pyrolyse, au refroidissement, à la réaction et à la sublimation dans les industries chimiques, des pesticides, agroalimentaires et agricoles. Ce sécheur est principalement utilisé dans les domaines suivants :

1. Produits chimiques organiques : résine, mélamine, aniline, stéarate, formiate de calcium et autres matières chimiques organiques et

intermédiaire

2. Produits chimiques inorganiques : carbonate de calcium, carbonate de magnésium, noir de carbone blanc, chlorure de sodium, cryolite, divers

sulfate et hydroxyde

3. Alimentation : céphalosporine, vitamine, sel, hydroxyde d'aluminium, thé, feuille de ginkgo et amidon

4. Fourrage et engrais : engrais potassique biologique, aliments protéiques, céréales, semences, herbicide et cellulose