Table des matières

Détails du produit

|

spécifications

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

capacité d'évaporation (kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

quantité de liquide traitée (kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

rendement du produit fini (kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

teneur en solides du liquide matériel (%)

|

18-30

|

|||||||

|

teneur en humidité du produit fini (%)

|

3-5

|

|||||||

|

puissance électrique (kW)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

source de chaleur

|

Vapeur et électricité

|

|||||||

|

Méthode de collecte du produit et son efficacité

|

Le dépoussiéreur humide à cyclone de classe un, deux ou trois étages est supérieur ou égal à 95%

|

|||||||

|

compteurs et instruments de contrôle automatique

|

indicateur de température de l'air non vicié et de l'air évacué

|

|||||||

|

température d'entrée d'air (℃)

|

160-220

|

|||||||

|

température de sortie d'air (℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

dimensions hors tout (mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

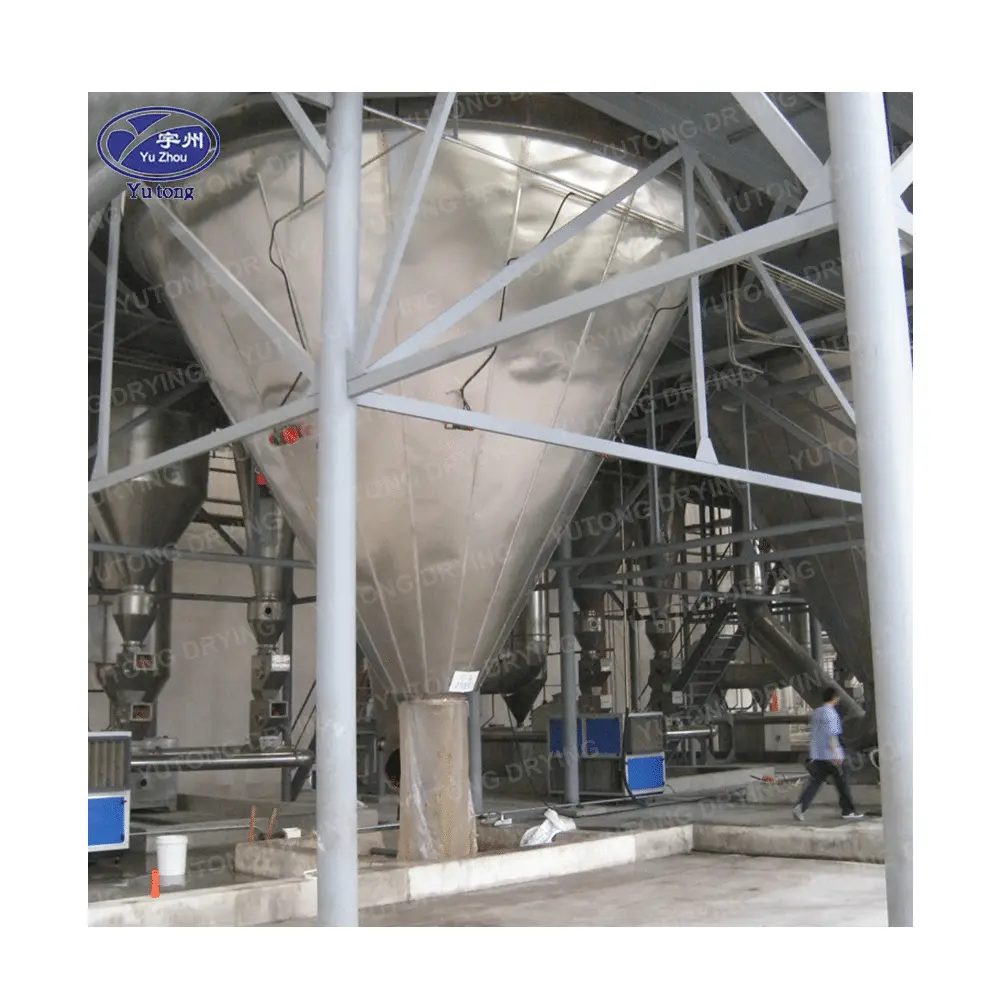

Milk Powder-Making Machine Product Profile

The Milk Powder Making Machine is a specialized and high-performance industrial device engineered to transform liquid milk into a powdered form. It combines advanced technology with robust construction, ensuring reliable and efficient production for the dairy and food industries.

Applications

Usine de produits alimentaires et de boissons :

As the core equipment in dairy product manufacturing, it is specifically designed for drying milk into powder. This process allows for easier storage, transportation, and a longer shelf-life of milk products. Additionally, its hygienic construction and precise drying control make it suitable for drying other food ingredients like fruit and vegetable powders, as well as flavourings.

It can be integrated into large-scale production lines, enabling high-volume production to meet market demands.

Commerce de détail et d'alimentation :

Small-scale versions of the milk powder-making machine can be used for in-shop drying operations. This could involve creating custom-blended milk powders with added flavours or nutrients. It can also serve as a demonstration tool to attract customers by showing the process of making fresh milk powder.

Food & Beverage Shops:

Similar to retail food shops, it can be used to produce milk powder or other dried food items on-site. This provides an opportunity for creating unique products and enhancing the store’s offerings.

Avantages

High-Quality Output:

The machine’s precise drying control ensures that the milk powder retains its nutritional value, flavour, and texture. It can achieve the ideal moisture content, which is crucial for the quality and shelf-life of the milk powder.

The hygienic construction prevents any contamination during the production process, resulting in safe and pure milk powder.

Efficient Production:

It is designed to handle large volumes of liquid milk, reducing the time and labour required for milk powder production. This high-efficiency production can significantly increase productivity in food & beverage factories.

The drying process is optimized to be energy-efficient, helping businesses save on operational costs.

Versatilité:

While primarily designed for milk powder production, its capabilities extend to drying other food ingredients, such as fruit and vegetable powders, as well as flavourings. This versatility allows food manufacturers to diversify their product lines using a single piece of equipment.

Reliability:

Built with high-quality materials and components, the milk powder-making machine is designed to withstand continuous use in industrial settings. It requires minimal maintenance, reducing downtime and ensuring consistent production.

Détails du produit

Mécanisme de séchage :

Spray Drying: This is a common method used in milk powder-making machines. Liquid milk is atomized into fine droplets and sprayed into a hot air chamber. The hot air quickly evaporates the moisture from the droplets, turning them into powder. This method ensures rapid and uniform drying, resulting in high-quality milk powder with good solubility.

Fluid-Bed Drying: In some models, a fluid-bed drying system may be incorporated. The milk powder is suspended in a stream of hot air, which allows for efficient heat transfer and drying. This method can be used for further drying or for agglomerating the powder particles to improve their flow properties.

Capacité:

Small-Scale Models: These are suitable for retail and food shops, with a production capacity ranging from a few kilograms to tens of kilograms of milk powder per hour. They are compact and easy to operate, requiring less space.

Industrial-Scale Models: For food & beverage factories, these models can produce hundreds or even thousands of kilograms of milk powder per hour. They are designed to be integrated into large-scale production lines and can handle high-volume milk processing.

Matériau de construction :

Exterior: The body of the machine is typically made of stainless steel. Stainless steel offers excellent corrosion resistance, especially when dealing with moisture-rich environments like milk processing. It is also easy to clean and maintain, meeting the strict hygiene standards of the food industry.

Interior Components: All parts that come into contact with the milk or the powder are made of food-grade materials. This includes the spray nozzles, drying chambers, and conveyor belts (if applicable). These materials are non-reactive with milk and ensure that the final product is safe for consumption.

Système de contrôle :

Manual Control: Basic models may have a manual control panel, allowing operators to adjust parameters such as temperature, air flow rate, and feed rate. This gives operators direct control over the drying process.

Automated Control: Advanced models are equipped with automated control systems. These systems can monitor and adjust multiple parameters in real-time, ensuring consistent product quality. They may also have features like self-calibration, data logging, and remote monitoring, which enhance the overall efficiency and management of the production process.

Caractéristiques de sécurité :

Over-Temperature Protection: To prevent overheating, the machine is equipped with sensors that detect the temperature of the drying chamber. If the temperature exceeds a safe limit, the heating system is automatically shut off.

Emergency Stop Buttons: Located at easily accessible positions on the machine, emergency stop buttons can quickly halt all operations in case of an emergency, protecting operators and the equipment.

Insulation: The drying chamber and other hot parts of the machine are well-insulated to prevent heat loss and to protect operators from accidental burns.

Caractéristiques

|

spécifications

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

capacité d'évaporation (kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

quantité de liquide traitée (kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

rendement du produit fini (kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

teneur en solides du liquide matériel (%)

|

18-30

|

|||||||

|

teneur en humidité du produit fini (%)

|

3-5

|

|||||||

|

puissance électrique (kW)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

source de chaleur

|

Vapeur et électricité

|

|||||||

|

Méthode de collecte du produit et son efficacité

|

Le dépoussiéreur humide à cyclone de classe un, deux ou trois étages est supérieur ou égal à 95%

|

|||||||

|

compteurs et instruments de contrôle automatique

|

indicateur de température de l'air non vicié et de l'air évacué

|

|||||||

|

température d'entrée d'air (℃)

|

160-220

|

|||||||

|

température de sortie d'air (℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

dimensions hors tout (mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

Ateliers de réparation de machines : peuvent être utilisés pour sécher des lubrifiants, des agents de nettoyage ou d'autres substances liquides liées à l'entretien et à la réparation des machines.

Usine de produits alimentaires et de boissons : Idéal pour sécher des ingrédients alimentaires tels que du lait en poudre, des poudres de fruits et de légumes, des arômes, etc., grâce à sa construction hygiénique et à son contrôle précis du séchage.

Fermes : Utile pour sécher les produits agricoles ou les sous-produits dans certains scénarios de transformation.

Commerce de détail et d'alimentation : Peut être utilisé pour des opérations de séchage à petite échelle ou des démonstrations liées aux produits alimentaires.

Travaux de construction : Peut prendre en charge le séchage de certains matériaux de construction ou adjuvants chimiques.

Énergie et mines : Applicable au séchage de réactifs chimiques ou d'échantillons dans des processus connexes.

Magasins d'alimentation et de boissons : Similaire aux usines alimentaires, il peut être utilisé pour le séchage en magasin d'aliments ou de mélanges personnalisés.

Notre sécheur-atomiseur industriel est un outil polyvalent et fiable pour de nombreux secteurs d'activité, offrant un séchage efficace, une longue durée de vie et une utilisation conviviale. Conçu pour répondre aux normes de qualité et de performance les plus strictes, il constitue un choix idéal pour toute application de séchage industriel.