Spray drying is a method of producing a dry powder from a liquid by rapidly drying it with a hot gas. It’s a preferred technique in the ceramic industry due to its ability to produce powders with uniform particle size distribution, which is crucial for consistent ceramic products.

The Basics of Spray Drying

Spray drying begins with a liquid slurry, which is typically a mixture of water and ceramic material. This slurry is then atomized into fine droplets, which are introduced into a drying chamber. The chamber is filled with hot gas, usually air, which evaporates the moisture from the droplets, leaving behind dry powder particles. This process not only ensures uniformity but also enhances the purity of the final product, reducing the risk of contamination.

Historical Context and Evolution

The use of spray drying in ceramics dates back several decades, evolving in tandem with advancements in technology. Initially developed for food and pharmaceutical industries, spray drying quickly found applications in ceramics due to its ability to produce fine, consistent powders. Over the years, technological innovations have improved the efficiency and scalability of spray dryers, making them indispensable in modern ceramic manufacturing.

Current Trends and Innovations

Today, the ceramic industry is witnessing a shift towards more sustainable and energy-efficient spray drying methods. Innovations include the use of renewable energy sources for heating and the implementation of advanced control systems for precise monitoring. Additionally, the integration of data analytics is helping manufacturers optimize the process, reduce waste, and improve overall product quality.

The Role of Spray Dryers

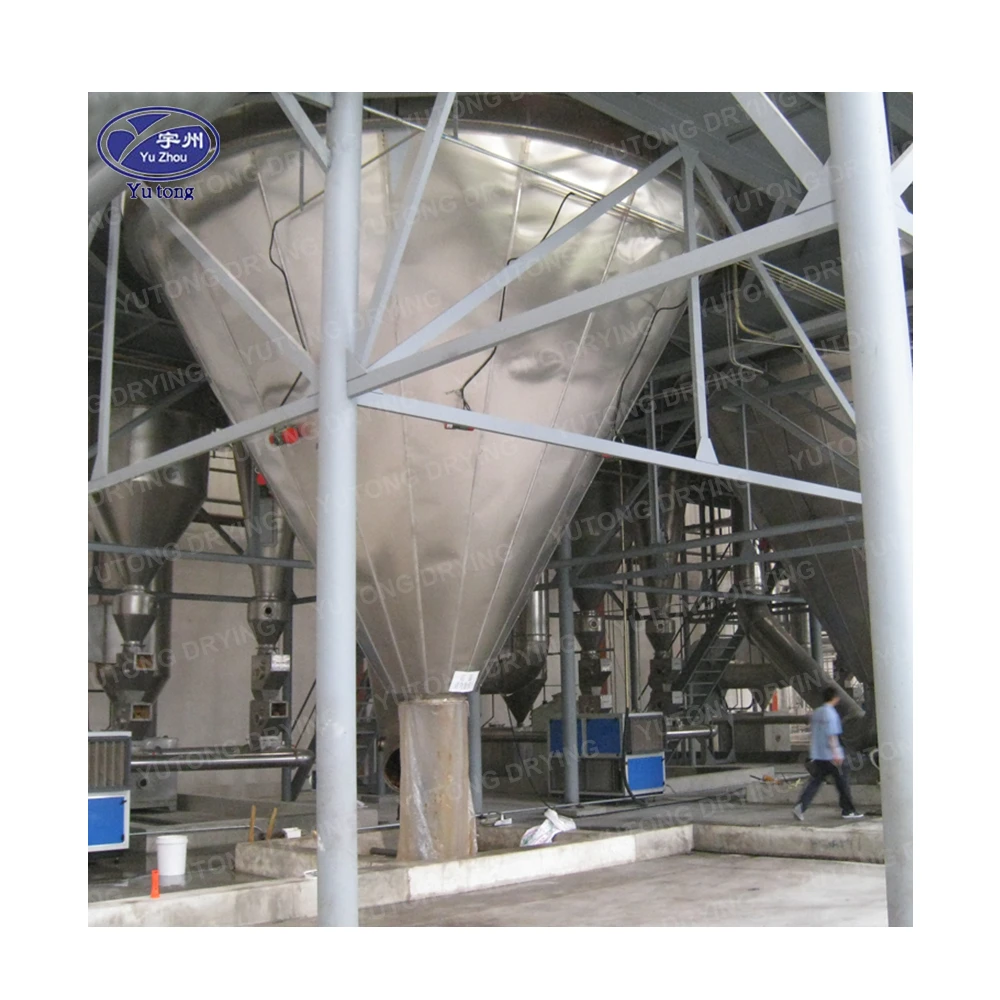

Spray dryers convert liquid ceramic slurry into fine, free-flowing powder. This process involves atomizing the liquid into a hot drying chamber. The moisture evaporates quickly, leaving behind dry particles that are then collected for further processing or packaging.

Atomization: The Core Process

Atomization is the process of transforming the liquid slurry into tiny droplets. This is achieved using different types of atomizers, including rotary, nozzle, and ultrasonic. Each type has its advantages, with the choice depending on the specific requirements of the ceramic product being manufactured. The goal is to produce droplets of uniform size, ensuring consistent drying and powder quality.

Drying Chamber Dynamics

The drying chamber is a critical component of a spray dryer, where the actual evaporation of moisture occurs. The design and size of the chamber can vary, but its function remains the same: to provide an environment where the droplets can be rapidly dried. The temperature, airflow, and residence time within the chamber are precisely controlled to maximize efficiency and minimize energy consumption.

Collection and Post-Processing

Once the drying process is complete, the powder particles are collected using cyclones or bag filters. These systems ensure that the fine particles are effectively captured and separated from the exhaust air. Post-processing may include additional drying, sieving, or blending to achieve the desired powder characteristics before it is packaged or sent for further manufacturing steps.

Importance of High Efficiency

High efficiency in spray drying means reduced energy consumption, lower operational costs, and improved environmental sustainability. A high efficiency ceramic spray dryer ensures optimal heat transfer and minimal energy waste, making it a cost-effective solution for manufacturers.

Energy Conservation and Optimization

Energy efficiency is paramount in spray drying, as the process can be energy-intensive. High efficiency dryers incorporate advanced heat recovery systems that capture and reuse heat from the exhaust air, significantly reducing energy consumption. This not only lowers operational costs but also contributes to a smaller carbon footprint, aligning with environmental sustainability goals.

Cost Reduction and Economic Impact

By minimizing energy consumption and maximizing output, high-efficiency spray dryers offer substantial cost savings. These savings can be reinvested into other areas of production or passed on to consumers through competitive pricing. Additionally, efficient dryers reduce wear and tear on components, resulting in lower maintenance costs and a longer equipment lifespan.

Environmental Sustainability

The ceramic industry is increasingly focusing on sustainability, and high efficiency spray dryers play a crucial role in this transition. By reducing energy consumption and emissions, these dryers help manufacturers meet environmental regulations and standards. Moreover, they support the industry’s efforts to adopt greener practices, such as using biodegradable or recyclable packaging for the final products.

Key Features of a High Efficiency Ceramic Spray Dryer

High efficiency ceramic spray dryers incorporate advanced technologies to enhance performance and reliability. Here are some essential features:

Advanced Atomization Techniques

The atomization process is critical in spray drying. Modern spray dryers employ advanced atomizers that ensure a uniform droplet size, resulting in consistently high-quality powder. This uniformity is crucial for high-quality ceramic products.

Types of Atomizers

There are several types of atomizers used in high-efficiency spray dryers, each suited for different applications. Rotary atomizers are ideal for high-capacity operations, while pressure nozzles offer precise control over droplet size and shape. Ultrasonic atomizers, though less common, provide exceptional uniformity for specialized applications. Selecting the right atomizer is key to achieving optimal drying results.

Enhancing Uniformity and Quality

Uniform droplet size is crucial for maintaining consistent powder quality, as it impacts both drying time and particle characteristics. Advanced atomization techniques ensure that each droplet is identical, leading to uniform evaporation and particle formation. This consistency is particularly important for ceramics, where even minor deviations can impact the final product’s performance and aesthetics.

Role in Innovation and Development

Atomization technology continues to evolve, with ongoing research focused on improving efficiency and reducing energy use. Innovations such as multi-fluid nozzles and hybrid atomizers are being explored to further enhance performance. These developments are paving the way for more versatile and adaptable spray drying solutions in the ceramic industry.

Enhanced Heat Exchange Mechanisms

Efficient heat exchange systems in spray dryers improve the drying rate while minimizing energy usage. These systems ensure that the maximum amount of heat is transferred to the ceramic slurry, enhancing the overall efficiency of the drying process.

Types of Heat Exchangers

Heat exchangers come in various forms, including tubular, plate, and shell-and-tube designs. Each type has its advantages, with plate heat exchangers being particularly effective for spray drying due to their compact size and high efficiency. The choice of heat exchanger depends on the specific requirements of the drying process and the characteristics of the slurry being dried.

Maximizing Heat Transfer Efficiency

Maximizing heat transfer is crucial for efficient spray drying. Advanced heat exchangers use materials with high thermal conductivity and incorporate design features that enhance heat transfer rates. This ensures that the slurry receives the maximum amount of heat, reducing drying time and energy consumption.

Innovations in Heat Exchange Technology

Recent innovations in heat exchange technology focus on improving durability and efficiency. Coatings that resist fouling and corrosion extend the lifespan of heat exchangers, while advanced designs enhance performance. These developments contribute to the overall efficiency of spray dryers, making them more reliable and cost-effective.

Robust Material and Construction

Durability is key in industrial equipment. High efficiency spray dryers are constructed from robust materials that withstand high temperatures and corrosive environments, ensuring longevity and minimal maintenance.

Material Selection and Durability

The materials used in constructing spray dryers must withstand harsh conditions, such as high temperatures and corrosive slurries. Stainless steel is commonly used due to its corrosion resistance and strength. Other materials, such as ceramics and specialized alloys, are also used for specific components to enhance durability and performance.

Design for Longevity

Design considerations play a significant role in the longevity of spray dryers. Features such as reinforced frames, protective coatings, and modular components enhance durability and ease of maintenance. These design elements ensure that the equipment can withstand the rigors of industrial use, providing reliable performance over extended periods of time.

Maintenance and Reliability

High-efficiency spray dryers are designed for minimal maintenance, featuring components that facilitate easy access. Automation and control systems help monitor equipment health, enabling proactive maintenance and minimizing downtime. This reliability is essential for maintaining production schedules and minimizing operational disruptions.

Automation and Control Systems

State-of-the-art spray dryers are equipped with automation and control systems that allow precise monitoring and adjustment of the drying parameters. This precision ensures consistent product quality and optimizes energy use.

Role of Automation in Spray Drying

Automation plays a crucial role in modern spray drying, enabling precise control over the entire process. Advanced control systems continuously monitor variables such as temperature, pressure, and humidity in real time, enabling immediate adjustments. This level of control ensures consistent product quality and maximizes energy efficiency.

Benefits of Advanced Control Systems

Advanced control systems offer numerous benefits, including reduced human error, improved safety, and enhanced process optimization. By continuously monitoring process parameters, these systems can detect anomalies and initiate corrective actions, minimizing waste and ensuring consistent product quality. Additionally, automation reduces the need for manual intervention, lowering labor costs and increasing operational efficiency.

Future Trends in Automation

The future of automation in spray drying is promising, with advancements in IoT and AI set to revolutionize the industry. Predictive maintenance, enabled by real-time data analytics, will further enhance equipment reliability and efficiency. These technologies will enable manufacturers to continuously optimize their processes, thereby reducing downtime and enhancing overall productivity.

Applications of Spray Drying Technology in Ceramics

Spray drying technology finds applications in various sectors within the ceramic industry:

Kaolin Spray Drying

Kaolin, a key raw material in ceramics, benefits from spray drying. The process ensures that kaolin particles are uniformly sized, enhancing their integration into ceramic products.

Importance of Kaolin in Ceramics

Kaolin is a crucial component in ceramic production, valued for its plasticity, whiteness, and chemical inertness. Spray drying enables the achievement of fine particle sizes and uniform distribution, which are essential for producing high-quality ceramic products. This consistency is vital for applications such as porcelain, where aesthetics and performance are paramount.

Spray Drying Process for Kaolin

The spray drying process for kaolin involves preparing a slurry, which is then atomized and dried to produce fine powder. This powder is characterized by its uniform particle size and low moisture content, making it ideal for ceramic manufacturing. The process also enhances kaolin’s flow properties, facilitating its integration into various ceramic formulations.

Advancements in Kaolin Spray Drying

Recent advancements in kaolin spray drying focus on improving energy efficiency and reducing environmental impact. Techniques such as heat recovery and advanced atomization are being employed to enhance process efficiency. These innovations ensure that the spray drying process remains cost-effective and sustainable, supporting the growing demand for high-quality ceramic products.

DORST and DOST Spray Dryers

DORST and DOST are renowned brands in the spray drying industry, known for their innovative designs and high efficiency. Their equipment is widely used in the ceramic industry for producing high-quality ceramic powders.

Overview of DORST and DOST Technologies

DORST and DOST are leaders in spray drying technology, offering equipment that combines efficiency, reliability, and innovation. Their dryers are specifically designed to meet the needs of the ceramic industry, featuring enhancements that improve performance and lower operational costs. These brands have built a reputation for delivering high-quality, durable equipment that consistently produces superior ceramic powders.

Key Features and Innovations

DORST and DOST spray dryers incorporate state-of-the-art technologies, such as advanced atomization systems and efficient heat exchangers. Their equipment is designed for ease of use, with automation and control systems that ensure precise monitoring and adjustment of drying parameters. These features contribute to consistent product quality and optimized energy use, making their dryers a preferred choice for ceramic manufacturers.

Customer Support and Service

Both DORST and DOST are known for their exceptional customer support, providing comprehensive maintenance and technical assistance. They offer training programs and after-sales service to ensure that their equipment operates at peak performance. This commitment to customer satisfaction has solidified their position as trusted partners in the ceramic industry.

Ceramic Powder Production

Spray drying plays a crucial role in producing ceramic powders used in the manufacture of tiles, tableware, and advanced ceramics. The process ensures that the powders have the desired properties for shaping and sintering.

Role of Spray Drying in Powder Production

Spray drying plays a vital role in producing ceramic powders with the specific properties required for various applications. The process enables precise control over particle size distribution, moisture content, and powder flow properties. These attributes are crucial for shaping and sintering, ensuring that the final ceramic products meet strict quality standards.

Applications in Tile and Tableware Manufacturing

In tile and tableware manufacturing, spray drying ensures that the ceramic powders have the consistency and purity needed for high-quality products. Uniform particle size distribution enhances the mechanical properties of the final product, while low moisture content prevents defects during firing. This precision is essential for meeting the aesthetic and functional requirements of modern ceramic designs.

Advanced Ceramics and Emerging Applications

Spray drying is also critical in the production of advanced ceramics used in applications ranging from electronics to aerospace. The process enables the production of powders with specific chemical compositions and microstructures tailored to meet the demands of cutting-edge technologies. As demand for advanced ceramics grows, spray drying will remain a cornerstone of innovation and development in this field.

Benefits of Using a High Efficiency Ceramic Spray Dryer

Employing a high efficiency ceramic spray dryer offers numerous benefits to manufacturers:

Consistent Product Quality

A high-efficiency dryer ensures a uniform particle size distribution, leading to consistent quality in the final ceramic product. This consistency is crucial for maintaining product quality and ensuring customer satisfaction.

Importance of Uniformity in Ceramics

Uniformity in ceramic powders is crucial for achieving consistent product quality. Variations in particle size or distribution can lead to defects during shaping or firing, which in turn affect the final product’s appearance and performance. High-efficiency spray dryers ensure that every batch meets stringent quality standards, thereby enhancing reliability and customer confidence.

Impact on Product Performance

Consistent product quality has a direct impact on the performance and durability of ceramic products. Uniform powders result in even sintering and optimal mechanical properties, ensuring that the final product meets or exceeds expectations. This reliability is essential for manufacturers looking to maintain their competitive edge and reputation in the market.

Role in Customer Satisfaction

Customer satisfaction is closely tied to product quality, and high efficiency spray dryers help manufacturers deliver consistent results. By ensuring uniformity and reliability, these dryers contribute to positive customer experiences and brand loyalty. This is particularly important in competitive markets, where quality is a key differentiator.

Energy Savings

With optimized heat transfer and reduced energy consumption, high-efficiency spray dryers result in significant cost savings. This efficiency also contributes to a reduced carbon footprint, aligning with sustainable manufacturing practices.

Reduction in Energy Costs

Energy costs are a significant component of manufacturing expenses, and high efficiency spray dryers help mitigate these costs. By optimizing heat transfer and minimizing waste, these dryers reduce energy consumption, leading to substantial savings over time. This efficiency allows manufacturers to allocate resources to other areas, such as research and development or market expansion.

Environmental Benefits

In addition to cost savings, energy-efficient spray dryers offer environmental benefits by reducing greenhouse gas emissions and conserving resources. These dryers align with industry efforts to adopt sustainable practices and meet regulatory requirements. By minimizing their carbon footprint, manufacturers can enhance their corporate social responsibility and improve their public image.

Alignment with Industry Standards

The push towards sustainability is driving the adoption of energy-efficient technologies across industries, and ceramics is no exception. High efficiency spray dryers help manufacturers comply with environmental standards and certifications, positioning them as leaders in sustainable manufacturing. This alignment with industry standards not only benefits the environment but also enhances the manufacturer’s reputation and competitiveness.

Enhanced Production Capacity

The advanced feature enables high efficiency for increased production capacity without compromising on quality. This capability enables manufacturers to meet growing demand efficiently.

Meeting Market Demand

As demand for ceramic products continues to grow, manufacturers must increase their production capacity to remain competitive. High-efficiency spray dryers enable manufacturers to scale up production without sacrificing quality, ensuring they can meet market demands effectively. This scalability is crucial for capturing new opportunities and expanding market share.

Flexibility and Adaptability

High efficiency spray dryers offer flexibility and adaptability, allowing manufacturers to adjust production parameters to meet changing market conditions. This versatility is essential for responding to fluctuations in demand or introducing new products. By maintaining consistent quality across different production scales, manufacturers can confidently explore new markets and applications.

Supporting Innovation and Growth

Increased production capacity supports innovation and growth by enabling manufacturers to experiment with new formulations and processes, thereby enhancing their ability to drive growth. High efficiency spray dryers provide the reliability and precision needed for research and development, allowing manufacturers to push the boundaries of ceramic technology. This capability is essential for staying ahead of industry trends and maintaining a competitive edge.

Reduced Operational Costs

Automation and advanced control systems minimize the need for manual intervention, reducing labor costs. Additionally, the durability and reliability of high efficiency spray dryers lower maintenance expenses.

Labor Savings through Automation

Automation plays a significant role in reducing labor costs by minimizing the need for manual intervention in the spray drying process. Advanced control systems handle routine monitoring and adjustments, freeing up personnel to focus on other tasks. This efficiency not only reduces labor expenses but also enhances overall productivity and operational efficiency.

Maintenance and Longevity

High-efficiency spray dryers are designed for minimal maintenance, featuring durable materials and robust construction that withstand the rigors of industrial use. This reliability reduces the frequency and cost of repairs, extending the equipment’s lifespan and lowering maintenance expenses. By minimizing downtime and maximizing uptime, manufacturers can optimize their operations and maintain consistent production schedules.

Economic Impact of Cost Reduction

Reducing operational costs has a significant economic impact, enabling manufacturers to reinvest their savings in other areas of their business. These savings can be used to fund research and development, expand production capacity, or enhance marketing efforts. By improving their bottom line, manufacturers can strengthen their competitive position and achieve long-term success in the ceramic industry.

How to Choose the Right Spray Dryer for Your Needs

Selecting the appropriate spray dryer requires careful consideration of several factors:

Assess Your Production Requirements

Evaluate your production scale, the type of ceramic products you manufacture, and your specific powder characteristics. This assessment will help you select a dryer with the right capacity and features.

Analyzing Production Volume

Consider the volume of production when selecting a spray dryer. A small-scale operation may require a compact unit, while larger manufacturers might need high-capacity equipment. Understanding your production needs ensures that the chosen dryer can handle current demands and accommodate future growth.

Understanding Product Specifications

Different ceramic products have unique specifications, such as particle size, moisture content, and purity requirements. Selecting a spray dryer that meets these specifications is crucial for maintaining product quality and consistency. This involves evaluating the dryer’s capabilities, such as its atomization techniques and heat exchange efficiency, to ensure it can deliver the desired results.

Matching Technology with Goals

Aligning the spray dryer technology with your production goals is essential for achieving optimal results. Consider whether you need a dryer that focuses on energy efficiency, automation, or flexibility. By matching the dryer’s features with your operational goals, you can ensure that it supports your strategic objectives and enhances overall efficiency.

Consider Energy Efficiency

Opt for dryers with advanced heat exchange systems and automation features that enhance energy efficiency. This choice will lead to long-term cost savings and environmental benefits.

Evaluating Heat Recovery Systems

Heat recovery systems are a key component of energy-efficient spray dryers, capturing and reusing heat from the exhaust air. When choosing a dryer, evaluate the effectiveness of its heat recovery system and its impact on energy consumption. A well-designed system can significantly reduce operational costs and improve environmental performance.

Assessing Automation and Control Features

Automation and control features play a critical role in enhancing energy efficiency. Advanced control systems enable precise monitoring and adjustment of drying parameters, optimizing energy use. Evaluate the level of automation in potential dryers and consider how it will impact your operations, both in terms of energy savings and process optimization.

Long-Term Environmental Impact

Consider the long-term environmental impact of the spray dryer, including its energy consumption and emissions. Choose a dryer that aligns with your sustainability goals and helps you meet regulatory requirements. By prioritizing energy efficiency, you can reduce your carbon footprint and contribute to more sustainable manufacturing practices.

Evaluate the Manufacturer’s Reputation

Select a reputable manufacturer recognized for its high-quality equipment and reliable customer support. Brands like DORST and DOST have a proven track record in the ceramic industry.

Researching Manufacturer History

Research the history and reputation of potential spray dryer manufacturers to ensure a reliable and trustworthy supplier. Look for companies with a strong track record of delivering high-quality, reliable equipment. Customer reviews, case studies, and industry awards can provide valuable insights into a manufacturer’s capabilities and reputation.

Assessing Customer Support Services

Customer support is a critical factor when choosing a spray dryer manufacturer. Ensure that the manufacturer offers comprehensive support services, including installation, training, and maintenance. A strong support network can help you maximize the performance of your equipment and minimize downtime, ensuring smooth and efficient operations.

Evaluating Product Portfolio

Consider the manufacturer’s product portfolio and whether it aligns with your needs. A diverse range of products indicates a manufacturer’s ability to meet various production requirements and adapt to changing market conditions. Evaluate the features and capabilities of different models to determine which best suits your operational goals and production demands.

Factor in Maintenance and Support

Ensure that the manufacturer provides comprehensive maintenance support and ensures the availability of spare parts. This support is crucial for minimizing downtime and extending the equipment’s lifespan.

Importance of Maintenance Services

Maintenance services are crucial for maintaining your spray dryer’s optimal performance. Select a manufacturer that provides regular maintenance checks and offers prompt response times for repairs. This proactive approach helps prevent unexpected breakdowns and extends the equipment’s lifespan, maximizing your investment.

Availability of Spare Parts

The availability of spare parts is crucial for minimizing downtime and maintaining efficient operations. Ensure that the manufacturer has a robust supply chain for spare parts, allowing for quick replacements when needed. This availability ensures that your spray dryer can continue operating smoothly without prolonged interruptions.

Support and Training Programs

Comprehensive support and training programs are valuable resources for optimizing the use of your spray dryer. Look for manufacturers that offer training for your staff on the operation, maintenance, and troubleshooting of their equipment. This education helps improve efficiency, reduce errors, and enhance overall productivity.

Future Trends in Spray Drying Technology

The future of spray drying in the ceramic industry is promising, with ongoing innovations aimed at further enhancing efficiency and sustainability:

Integration of IoT and AI

The integration of IoT and AI technologies in spray dryers will enable real-time monitoring and predictive maintenance, further improving efficiency and reducing downtime.

Real-Time Monitoring Capabilities

IoT technology allows for real-time monitoring of spray dryer operations, providing valuable data on process parameters and equipment health. This capability enables manufacturers to make informed decisions, optimize operations, and reduce waste. By leveraging IoT, manufacturers can enhance the efficiency and reliability of their spray drying processes.

Predictive Maintenance Strategies

AI-driven predictive maintenance uses data analytics to identify patterns and predict equipment failures before they occur. This proactive approach minimizes downtime and extends the lifespan of spray dryers. By implementing predictive maintenance, manufacturers can enhance operational efficiency and lower maintenance costs, thereby ensuring consistent production.

Enhanced Process Optimization

AI technology can optimize spray drying processes by analyzing data and identifying opportunities for improvement. Machine learning algorithms can adjust parameters in real time, maximizing energy efficiency and product quality. This level of optimization enables manufacturers to achieve their production goals and maintain a competitive edge in the market.

Development of Eco-Friendly Solutions

Research is focused on developing eco-friendly spray drying technologies that minimize environmental impact while maintaining high performance.

Sustainable Materials and Designs

The development of eco-friendly spray drying technologies involves using sustainable materials and designs that reduce environmental impact. Innovations include biodegradable components, energy-efficient designs, and recyclable packaging. These advancements support the ceramic industry’s shift towards more sustainable manufacturing practices.

Reducing Emissions and Waste

Eco-friendly spray dryers aim to minimize emissions and waste by improving energy efficiency and utilizing advanced filtration systems. By reducing the environmental footprint of the spray drying process, manufacturers can align with regulatory requirements and enhance their sustainability credentials. This focus on reducing emissions and waste is essential for meeting the demands of environmentally conscious consumers.

Aligning with Global Sustainability Goals

As global sustainability goals continue to influence industry practices, the development of eco-friendly spray drying solutions is becoming increasingly important. Manufacturers are investing in research and development to create technologies that support a more sustainable future. By aligning with these global goals, the ceramic industry can contribute to a cleaner, more sustainable world.

Customization and Flexibility

Future spray dryers will offer greater customization options to meet the specific needs of various ceramic products, thereby enhancing versatility and expanding their application range.

Tailoring Dryers to Specific Applications

Customization allows manufacturers to tailor spray dryers to specific applications, optimizing performance and efficiency. This flexibility is particularly important for specialized ceramic products that require unique powder characteristics. By offering customizable options, manufacturers can ensure that their equipment meets the precise needs of their production processes.

Enhancing Versatility and Adaptability

Versatility and adaptability are key advantages of customizable spray dryers. These features enable manufacturers to switch between different products or processes with minimal adjustments, enhancing operational flexibility. This adaptability is crucial for responding to changing market demands and exploring new opportunities in the ceramic industry.

Supporting Innovation and Development

Customization supports innovation and development by allowing manufacturers to experiment with new formulations and processes. Customizable spray dryers provide the precision and control needed for research and development, enabling manufacturers to push the boundaries of ceramic technology. This capability is essential for maintaining a competitive edge and driving industry advancements.

Conclusion

A high efficiency ceramic spray dryer is an invaluable asset for manufacturers in the ceramic industry. Its ability to deliver consistent product quality, energy savings, and operational efficiency makes it a cornerstone of modern ceramic powder processing. As technology continues to evolve, the future of spray drying promises even greater advancements, paving the way for a more sustainable and efficient ceramic industry.

Embracing Technological Advancements

The ceramic industry is embracing technological advancements to enhance efficiency and sustainability. High efficiency spray dryers are at the forefront of this transformation, offering innovative solutions that support manufacturers’ goals. By adopting these technologies, manufacturers can improve their processes, reduce costs, and contribute to a more sustainable future.

The Role of Innovation in Future Success

Innovation is a key driver of success in the ceramic industry, and spray drying technology is no exception. Ongoing research and development are yielding breakthroughs that enhance performance and expand the applications of these technologies. By investing in innovation, manufacturers can stay ahead of industry trends and maintain their competitive edge in a rapidly evolving market.

A Sustainable Path Forward

The future of the ceramic industry lies in sustainable practices and technologies. High efficiency spray dryers play a critical role in this journey, offering solutions that reduce environmental impact while maintaining high performance. As manufacturers continue to prioritize sustainability, the adoption of these technologies will pave the way for a cleaner, more efficient, and prosperous ceramic industry.