Vacuum drying equipment operates by reducing the pressure inside the drying chamber, which lowers the boiling point of the liquid to be evaporated. This process allows drying to occur at lower temperatures, making it ideal for heat-sensitive materials. Unlike conventional drying methods, vacuum drying ensures minimal thermal degradation and maintains the integrity of the materials being processed.

The Science Behind Vacuum Drying

The fundamental principle of vacuum drying involves reducing the atmospheric pressure within the drying chamber. By doing so, the boiling point of the liquid is significantly lowered, allowing evaporation to occur at much lower temperatures. This is particularly advantageous for materials sensitive to heat, as it prevents their degradation during the drying process.

Historical Context and Evolution

Vacuum drying technology has evolved significantly since its inception. Initially developed to address the limitations of traditional drying methods, it has seen continuous improvements in efficiency and capabilities. Innovations have been driven by the need for better energy utilization and enhanced product quality, making it a staple in modern industrial processes.

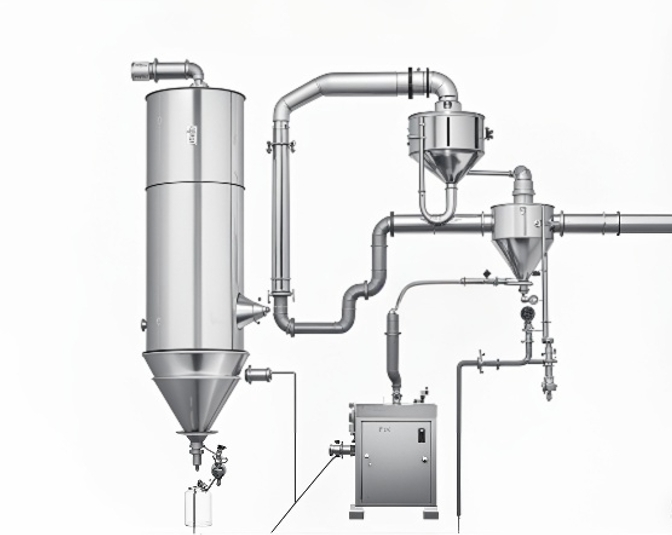

Components of Vacuum Drying Systems

A typical vacuum drying system consists of several critical components, including the drying chamber, vacuum pump, and control systems. Each component plays a vital role in ensuring the efficiency and effectiveness of the drying process. Understanding the function and interplay of these components is essential for optimal performance.

Key Advantages of Vacuum Drying Technology

Vacuum drying technology offers numerous advantages over traditional drying methods, including:

Energy Efficiency

By reducing the boiling point, vacuum drying uses less energy, resulting in lower operational costs. The energy savings are achieved through reduced heat requirements and faster drying times. This efficiency not only benefits the bottom line but also aligns with sustainability goals by reducing the carbon footprint of industrial operations.

Enhanced Product Quality

The gentle drying process prevents thermal damage, preserving the quality and characteristics of the product. This is crucial for industries like pharmaceuticals, where the potency and efficacy of compounds must be maintained. The preservation of flavors, colors, and nutrients in food processing further underscores the importance of this technology.

Faster Drying Times

The reduced pressure environment accelerates the drying process, increasing throughput. This improvement in drying speed allows industries to meet high production demands without compromising on quality. Faster drying times also contribute to energy savings, making the process more cost-effective and environmentally friendly.

Versatility Across Industries

Vacuum drying is suitable for a wide range of materials, including pharmaceuticals, food products, and heat-sensitive chemicals. Its adaptability to various industry needs makes it a versatile solution for multiple applications. The technology can be customized to meet specific drying requirements, enhancing its applicability across different sectors.

Selecting the Right Vacuum Drying Equipment

When selecting vacuum drying equipment, several factors must be considered to ensure optimal performance and cost-effectiveness.

Capacity and Size

The capacity of vacuum drying equipment is a crucial consideration. High-capacity dryers are necessary for large-scale industrial operations. It’s essential to choose equipment that matches your production needs to avoid bottlenecks and inefficiencies. Understanding your operational scale and future growth projections is key to making the right choice.

Material Compatibility

Different industries process a variety of materials, each with unique drying requirements. Ensure that the vacuum drying equipment you select is compatible with the specific materials you work with, whether they are powders, granules, or liquids. Compatibility ensures that the drying process is efficient and that the final product meets quality standards.

Control and Automation

Modern vacuum drying equipment often comes equipped with advanced control systems that allow for precise regulation of temperature, pressure, and drying times. Automation features can significantly enhance operational efficiency and consistency. These systems reduce human error and enable real-time adjustments, ensuring optimal drying conditions at all times.

Price Considerations

The vacuum drying equipment price can vary depending on factors such as capacity, features, and manufacturer. It’s important to balance cost with performance to achieve the best return on investment. Analyzing the total cost of ownership, including maintenance and energy consumption, provides a clearer picture of the long-term value of the equipment.

Leading Vacuum Drying Equipment Manufacturers

Several manufacturers stand out in the vacuum drying equipment industry for their innovation and reliability.

Manufacturer Spotlight: InnovateDry

InnovateDry is a leader in vacuum drying technology, offering a range of high-efficiency vacuum drying equipment tailored to various industrial applications. Their equipment is known for its durability, precision, and energy efficiency. InnovateDry continually invests in research and development, ensuring its products remain at the forefront of technological advancements.

Manufacturer Spotlight: DryTech Solutions

DryTech Solutions has earned a reputation for providing cutting-edge vacuum drying solutions that cater to the needs of the pharmaceutical and food processing industries. Their equipment boasts advanced control systems and robust construction. By focusing on customer feedback and industry needs, DryTech Solutions consistently delivers equipment that meets the highest standards.

Other Notable Manufacturers

Beyond InnovateDry and DryTech Solutions, other companies contribute significantly to the field of vacuum drying technology. These manufacturers offer a range of products that vary in features and price points, providing options for businesses of all sizes. Evaluating the offerings of these companies can help in finding the perfect fit for specific industrial requirements.

Vacuum Drying Equipment Suppliers

Selecting the right supplier is as crucial as choosing the right equipment. Reputable vacuum drying equipment suppliers provide not only the machinery but also after-sales support, maintenance, and training to ensure seamless integration into your production line.

Supplier Considerations

- Reputation: Research the supplier’s reputation in the industry. Look for customer reviews and case studies to gauge their reliability and customer satisfaction. A trusted supplier will have a proven track record of delivering high-quality equipment and support.

- Technical Support: Ensure the supplier offers comprehensive technical support and maintenance services to minimize downtime. Prompt and efficient support can significantly impact the smooth operation of your drying processes.

- Customization Options: Some suppliers offer customization options to tailor the equipment to your specific needs, enhancing its suitability for your processes. Customization can lead to improved efficiency and product quality, providing a competitive edge.

Long-term Partnerships

Building long-term relationships with suppliers can lead to benefits such as priority service, better pricing, and the ability to influence future product development. A strong partnership can provide stability and assurance, allowing businesses to focus on their core operations without worrying about equipment issues.

Training and Support Services

Suppliers that offer comprehensive training and support services help ensure that your team can effectively operate and maintain the equipment. This not only enhances efficiency but also extends the lifespan of the machinery, maximizing the return on your investment.

Innovations in Vacuum Drying Technology

The field of vacuum drying technology is constantly evolving, with manufacturers and researchers striving to improve efficiency and sustainability.

Energy-Saving Features

Newer models of vacuum drying equipment incorporate energy-saving features such as heat recovery systems, which capture and reuse heat from the drying process, further reducing energy consumption. These innovations not only cut costs but also support sustainability initiatives, making them attractive to environmentally conscious companies.

Advanced Control Systems

The integration of IoT and smart technologies into vacuum drying equipment allows for real-time monitoring and control, optimizing the drying process and enabling predictive maintenance. This level of control helps prevent potential issues before they occur, ensuring consistent product quality and reducing downtime.

Sustainable Materials and Practices

Manufacturers are increasingly focusing on using sustainable materials and practices in the production of vacuum drying equipment. This shift not only reduces the environmental impact but also aligns with the values of eco-conscious consumers and businesses. Sustainable practices in manufacturing further enhance the appeal of vacuum drying technology.

Applications of Vacuum Drying Equipment

Vacuum drying equipment finds applications across various industries due to its versatility and effectiveness.

Pharmaceutical Industry

In the pharmaceutical industry, vacuum drying is crucial for drying active pharmaceutical ingredients (APIs) and ensuring the stability of sensitive compounds. The low-temperature drying process helps maintain the efficacy of the drugs. This precision is vital in ensuring that medicines meet safety and effectiveness standards.

Food Processing

For the food industry, vacuum drying offers the advantage of preserving flavors, colors, and nutrients in dehydrated products. It is commonly used for drying fruits, vegetables, and herbs. The gentle process ensures that the nutritional value of the food remains intact, providing consumers with healthier options.

Chemical Manufacturing

In chemical manufacturing, vacuum drying is employed to dry heat-sensitive chemicals, ensuring that their properties remain intact throughout the process. This application is critical in maintaining the quality and functionality of chemical products, which can be sensitive to temperature changes.

Emerging Applications

Beyond traditional industries, vacuum drying is finding new applications in emerging fields such as biotechnology and nanotechnology. As these sectors grow, the demand for precise and efficient drying methods will likely increase, further expanding the role of vacuum drying equipment.

Conclusion

High-efficiency vacuum drying equipment is indispensable for industries that demand precision, energy efficiency, and product quality. By understanding the key factors in selecting the right equipment and staying informed about the latest innovations, businesses can optimize their drying processes and achieve superior results.

Investing in cutting-edge vacuum drying technology not only enhances operational efficiency but also contributes to sustainability by reducing energy consumption and minimizing waste. As the industry continues to evolve, embracing these advancements will position companies at the forefront of industrial drying applications.

In conclusion, the adoption of high-efficiency vacuum drying equipment is a strategic decision that offers significant benefits. Companies that leverage this technology can expect improved product quality, lower operational costs, and a competitive edge in their respective markets. As advancements continue to unfold, staying ahead of the curve will be essential for maintaining industry leadership.