Table of Contents

Product Detail

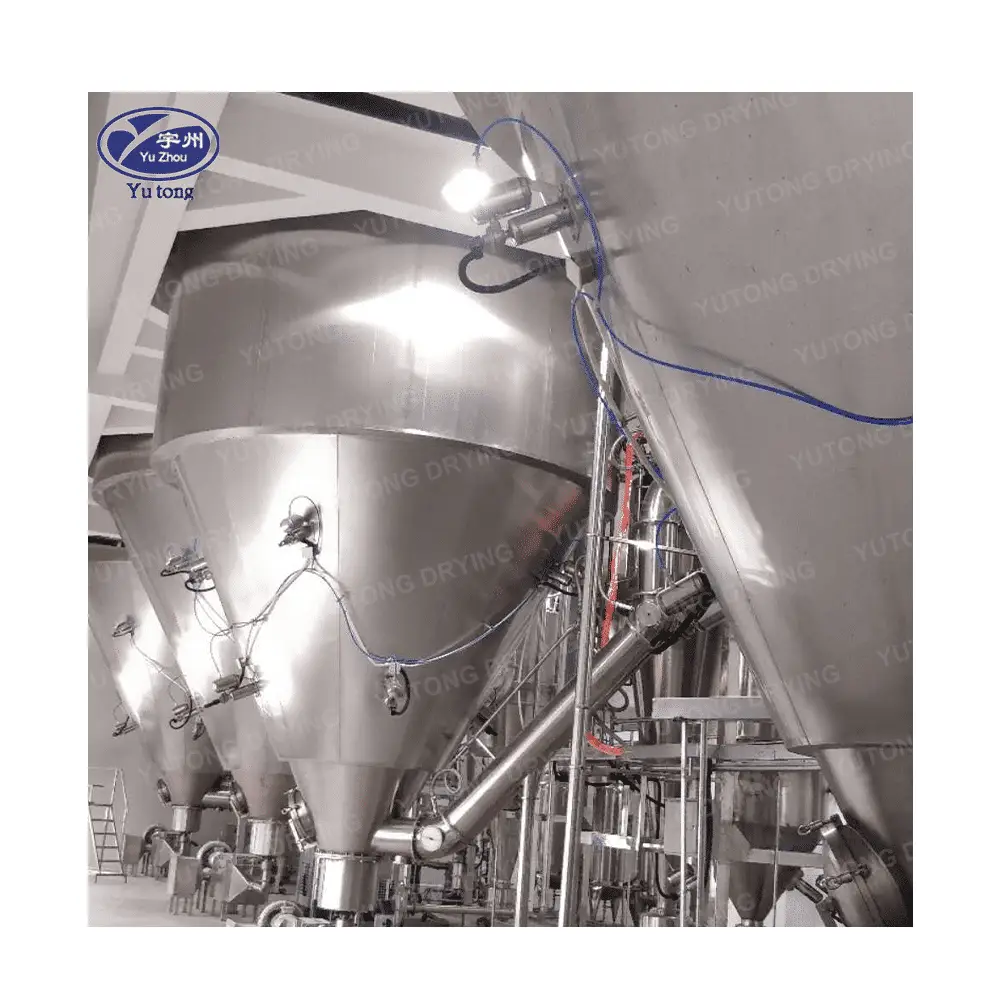

Basic Principle: High-speed centrifuge atomizing for the extraction of traditional Chinese medicine is an application of the centrifuge atomizing technique. It also uses high-speed atomization to make liquid material into foggy droplets, fully contact hot air to finish instant drying, and get the final powder product.

Main Features 1) The tower body is equipped with a cool air jacket to reduce the inside tower temperature and eliminate the product preheating and softening phenomenon

2) The atomizer on top of the tower is equipped with a cooling device to reduce the atomizer temperature, effectively eliminate material return to the top in eddy current, and avoid the preheat coking phenomenon. The owner’s body and pipeline are equipped with a manual quick-open cleaning hole and a drainage hole. The ClP automatic cleaning device can also be equipped if needed.

4) An automatic control constant temperature feeding tank can be equipped

5) Manual high-pressure washing tools can be offered as accessories together with the spray dryer.6) All product contact parts are made with Stainless Steel (or whole parts with stainless steel). 7) The product collection method adopts two grade cyclones and a water film duster.

8) Air inlet temperature is automatically and continuously controlled, led by which is interlocked with feeding. An air sweeping device can be optional for some products

Specifications

|

spec

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

evaporation capacity(kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

Solid content of material liquid( %)

|

18-30

|

|||||||

|

Moisture content of finished product( %)

|

3-5

|

|||||||

|

electric power(kw)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

heat source

|

Steam plus electricity

|

|||||||

|

The collecting method of the product and its efficiency

|

Grade one or two, or three stage cyclone wet dust remover is greater than or equal to 95%

|

|||||||

|

automatic control meters and instruments

|

indicator of non-air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

160-220

|

|||||||

|

temperature of air outlet(℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Applications

Applicable Industries: Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Retail, Food & Beverage Shops