Spray drying equipment involves a complex process where a liquid solution is sprayed into a hot chamber, causing the liquid to evaporate and leaving behind a fine powder. This technique is highly effective for preserving the quality and flavor of food products, like coffee, making it a staple in the food industry.

The Spray Drying Process

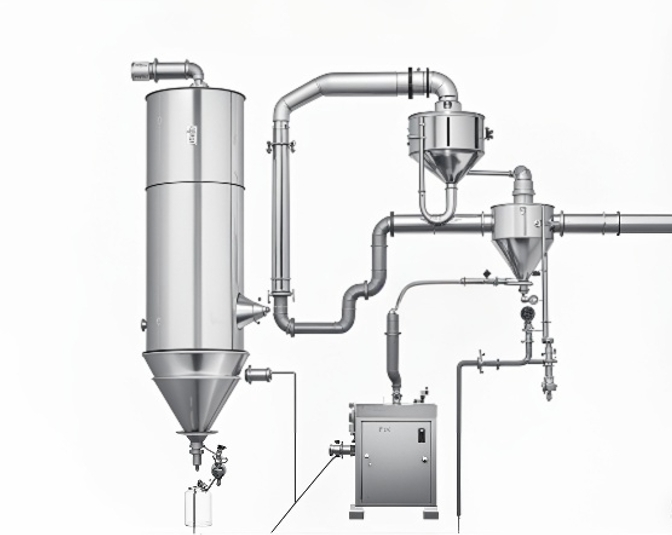

The spray drying process begins with the preparation of a liquid feedstock, which is often a solution, emulsion, or slurry. This feedstock is then atomized into a fine mist using various atomization techniques such as rotary, pressure, or two-fluid nozzles. Once atomized, the droplets are introduced into a drying chamber where they come into contact with hot air. This rapid contact causes the moisture within the droplets to evaporate almost instantly, leaving behind a dry powder. The speed and efficiency of this process are what make spray drying so valuable in industries that require quick drying times and precise control over particle size and moisture content.

Benefits of Spray Drying

One of the key advantages of spray drying is the ability to produce powders with a consistent and uniform particle size, which is essential in industries like pharmaceuticals where dosage and solubility are critical. Additionally, spray drying is capable of producing powders with a low moisture content, which extends the shelf life of products such as milk powder and coffee. This method also allows for the preservation of volatile compounds, maintaining the flavor and nutritional content of food products. Finally, the scalability of spray drying—from small laboratory setups to large industrial plants—makes it a versatile choice for businesses of all sizes.

Industries That Rely on Spray Drying

The versatility of spray drying makes it indispensable across various industries. In the food sector, it’s used for producing everything from powdered milk and eggs to flavors and colorings. The pharmaceutical industry utilizes spray drying for creating drugs with improved solubility and bioavailability. In the chemical industry, spray drying is employed to produce catalysts, detergents, and other fine chemicals. Even the ceramics industry benefits from spray drying, using it to produce granulated powders for advanced ceramic products. Understanding these applications helps in assessing the potential benefits and returns on investing in spray drying equipment.

Types of Spray Drying Machines

There are several types of spray dryers available, each designed for specific applications and production scales. The most common types include:

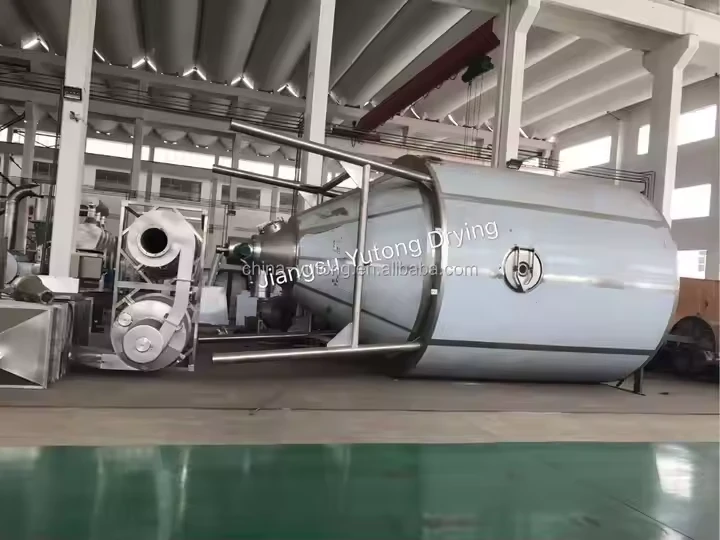

Centrifugal Spray Dryers

Centrifugal spray dryers are designed for high-capacity production and are often used in industries where continuous processing is necessary. These machines utilize a high-speed rotating disc to atomize the liquid feed into fine droplets. The centrifugal force generated by the disc ensures uniform droplet size, which is critical for achieving consistent product quality. Due to their large capacity and efficiency, centrifugal spray dryers are ideal for applications such as milk powder and instant coffee production, where large volumes need to be processed quickly and efficiently.

Pressure Nozzle Spray Dryers

Pressure nozzle spray dryers are suitable for applications where precise control over particle size and distribution is required. These machines use high-pressure pumps to force the liquid feed through a nozzle, creating droplets of specific sizes. This method is particularly beneficial for producing products that require uniformity, such as pharmaceuticals and specialty chemicals. The ability to adjust the nozzle pressure and flow rate allows for flexibility in controlling the final product’s characteristics, making pressure nozzle spray dryers a popular choice in industries where quality control is paramount.

Fluidized Spray Dryers

Fluidized spray dryers are often used for drying heat-sensitive materials that require gentle handling. In this type of spray dryer, the atomized droplets are introduced into a chamber where they are suspended in a stream of hot air, creating a fluidized bed. This method ensures even drying and prevents the degradation of sensitive compounds, making it ideal for drying enzymes, proteins, and other biological materials. The gentle drying process of fluidized spray dryers helps preserve the functional properties of the product, which is essential in industries such as food and pharmaceuticals where product integrity is crucial.

Factors Affecting Spray Drying Equipment Prices

When looking for spray drying equipment for sale, several factors can influence the price. Here’s what to consider:

Size and Capacity

The size and capacity of the spray dryer are significant determinants of its price. Larger machines capable of handling higher volumes will naturally cost more than smaller ones. It’s essential to assess your production needs to avoid over- or under-investing. Consider the scalability of your operations and whether your business plans to expand in the future. Opting for a machine that can accommodate growth might be more cost-effective in the long run than purchasing new equipment as your production increases.

Material and Build Quality

The materials used in the construction of the spray dryer impact its durability and price. Stainless steel models are common due to their resistance to corrosion and ease of cleaning, but they are more expensive than models made from other materials. However, the investment in high-quality materials can pay off in terms of longevity and reduced maintenance costs. Additionally, consider the construction’s compliance with industry standards and regulations, especially if you’re producing food or pharmaceutical products where hygiene and safety are paramount.

Technology and Features

Advanced features and technologies, such as automation, precise control systems, and energy efficiency, can increase the cost of spray drying equipment. While these features may add to the initial expense, they often result in long-term savings and improved product quality. Automation can reduce labor costs and increase production efficiency, while energy-efficient models can significantly lower operational expenses. Evaluate the potential return on investment these features offer and how they align with your production goals.

Brand and Manufacturer

Reputable brands and manufacturers may charge more for their equipment due to their proven track record and reliability. However, opting for a well-known brand can provide peace of mind in terms of customer support and availability of spare parts. Established manufacturers often offer comprehensive warranties and service packages, which can be invaluable in minimizing downtime and ensuring consistent production. Research the manufacturer’s reputation, customer reviews, and service offerings to make an informed decision.

Cost of New vs. Used Spray Drying Equipment

When considering the cost of spray drying equipment, you have the option of buying new or used. Both options have their pros and cons.

New Spray Drying Equipment

Purchasing new equipment ensures you get the latest technology and a warranty. It’s a safe choice if you require specific features or a customized setup. However, new machines come with a higher price tag. The benefits of buying new include access to the manufacturer’s support and training resources, which can be crucial for seamless integration into your production line. Additionally, new equipment often includes the latest safety features and compliance with current industry standards, reducing regulatory concerns.

Used Spray Drying Equipment

Used spray drying equipment is often more affordable and can be a cost-effective solution if you’re on a budget. However, it’s crucial to thoroughly inspect used equipment for any signs of wear and tear. Ensure that it meets your production needs and comes from a reliable source. Request maintenance records and test the equipment under operational conditions to verify its performance. While the initial cost savings can be significant, factor in potential repair expenses and the availability of replacement parts when evaluating used equipment.

Considerations for Leasing Equipment

Leasing spray drying equipment is another option that offers flexibility and reduced upfront costs. Leasing allows you to upgrade to newer models more frequently, ensuring access to the latest technology without the commitment of ownership. It can also provide tax advantages and free up capital for other business investments. However, consider the terms of the lease agreement, including maintenance responsibilities and potential penalties for early termination, to ensure it aligns with your business strategy.

Pricing Examples: What to Expect

To give you a rough idea of spray drying equipment costs, here are some examples:

Small-Scale Spray Dryers

Ideal for laboratory use or small production runs, these machines can range from $10,000 to $50,000. Small-scale spray dryers are often used in research and development settings where precision and control over small batches are crucial. They are also suitable for niche markets or startups looking to test new products without committing to large-scale production. Consider the specific features and capabilities you need, such as the ability to handle different feedstocks or the inclusion of advanced control systems, when evaluating small-scale options.

Medium-Scale Spray Dryers

Suitable for medium-sized operations, prices typically range from $50,000 to $200,000. Medium-scale spray dryers are designed for businesses that have established markets and need to increase production capacity. These machines offer a balance between cost and output, making them a popular choice for growing companies. Evaluate the potential for future scalability and whether the equipment can be easily upgraded or expanded to accommodate increased demand.

Large-Scale Spray Dryers

Designed for industrial-scale production, these machines can cost anywhere from $200,000 to over $1 million. Large-scale spray dryers are essential for companies with high-volume production requirements, such as those in the food processing or chemical manufacturing industries. The investment in large-scale equipment can be justified by the economies of scale achieved through increased efficiency and reduced per-unit production costs. When considering large-scale options, assess the infrastructure requirements, such as space and utilities, to ensure seamless integration into your facility.

Buying Spray Drying Equipment: Tips and Considerations

When purchasing spray drying equipment, consider the following tips to make an informed decision:

Assess Your Needs

Determine your production capacity, the type of product you will be drying, and any specific requirements you have. This information will guide you in selecting the right equipment. Consider not only your current production demands but also potential future needs as your business grows. This foresight can prevent the need for frequent upgrades and ensure you invest in equipment that supports your long-term goals.

Research Manufacturers

Look for manufacturers with a good reputation and positive customer reviews. Consider visiting their facilities if possible to see their equipment in action. This firsthand experience can provide valuable insights into the quality and reliability of the equipment and the level of customer service offered by the manufacturer. Additionally, engage with industry peers and networks to gather recommendations and feedback on different manufacturers to aid in your decision-making process.

Evaluate Total Cost of Ownership

Consider not only the initial purchase price but also the ongoing costs, such as maintenance, energy consumption, and spare parts availability. The total cost of ownership can significantly impact your return on investment, so it’s important to factor in these expenses when comparing different options. Request detailed cost breakdowns from manufacturers and inquire about service packages or maintenance contracts that can help manage long-term expenses.

Seek Professional Advice

If you’re new to spray drying, consulting with industry experts or engineers can provide valuable insights and help you choose the right equipment. Professional advice can guide you through the technical aspects of spray drying, such as selecting the appropriate drying parameters and optimizing your production process. Experts can also assist in assessing the compatibility of different equipment options with your specific production requirements, ensuring you make a well-informed decision.

Conclusion

Investing in spray drying equipment is a significant decision that requires careful consideration of various factors, including cost, technology, and production needs. By understanding the components that affect spray drying machine price and following the tips provided, you can make an informed decision that meets your business goals. Whether you’re producing instant coffee or pharmaceuticals, the right spray dryer can enhance your production capabilities and product quality. Taking the time to research and evaluate your options thoroughly will ensure that you select equipment that not only meets your immediate needs but also supports your long-term success in the competitive marketplace.