In today’s fast-paced world, preserving food efficiently and effectively is more important than ever. Among the many methods available, vacuum drying stands out as a particularly advantageous option. This method helps in preserving the nutritional value, extending shelf life, and maintaining the quality of fruits and vegetables. But what exactly is vacuum drying, and how does it benefit our everyday fruits and vegetables? Let’s dive into this fascinating topic.

What is Vacuum Drying?

Vacuum drying is a dehydration process where moisture is removed from fruits and vegetables under reduced pressure. This method reduces the boiling point of water, allowing it to evaporate at lower temperatures. As a result, fruits and vegetables are dried without being subjected to high heat, preserving their nutritional qualities and flavors.

The Science Behind Vacuum Drying

The core principle of vacuum drying revolves around physics and thermodynamics. By lowering the atmospheric pressure inside the drying chamber, the boiling point of water decreases significantly. This means that water can evaporate at temperatures much lower than its usual boiling point of 100°C. Such conditions prevent the thermal degradation of sensitive compounds, protecting the integrity of vitamins, minerals, and phytonutrients present in fruits and vegetables.

Equipment Used in Vacuum Drying

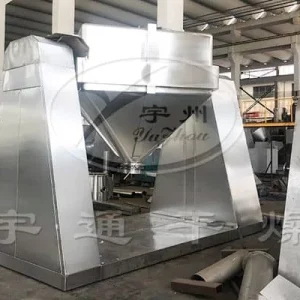

At the heart of vacuum drying technology is the vacuum tray dryer. This equipment consists of a sealed chamber where the food items are placed on trays. A vacuum pump creates a low-pressure environment, facilitating moisture removal. The dryer is equipped with heating elements that provide gentle heat, ensuring even drying across all trays. The sophistication of the machinery ensures that the process is efficient, though it requires regular maintenance to function optimally.

Historical Development of Vacuum Drying

The concept of vacuum drying has evolved over the years, initially used in the chemical and pharmaceutical industries. Its adaptation for food preservation came as a response to the need to maintain high-quality produce over extended periods. The technological advancements in the 20th century, particularly in vacuum engineering and material sciences, have refined the process, making it more accessible and efficient for food processing applications.

Benefits of Vacuum Drying Fruits and Vegetables

Vacuum drying offers several benefits over traditional drying methods. Here are some reasons why it’s becoming increasingly popular:

Preservation of Nutrients

One of the primary advantages of vacuum drying is its ability to preserve nutrients. Since the process occurs at lower temperatures, essential vitamins and minerals are less likely to degrade. This means that vacuum-dried fruits and vegetables often retain more of their original nutritional value compared to those dried using conventional methods.

Retention of Vitamins and Minerals

Vitamins like C, A, and B-complex are highly sensitive to heat. Traditional drying methods often result in the loss of these crucial nutrients. However, vacuum drying minimizes this loss, ensuring that the nutritional profile of the dried product closely mirrors that of the fresh produce. Consumers benefit from a healthier product, which can be particularly important for those relying on dried foods as a significant part of their diet.

Preservation of Antioxidants

Antioxidants, responsible for combating oxidative stress in our bodies, are abundant in fruits and vegetables. The gentle drying process of vacuum drying ensures these compounds remain intact. Consequently, consumers can enjoy the health benefits associated with antioxidants, such as reduced risk of chronic diseases and improved overall health.

Enzyme Activity Maintenance

Enzymes play a crucial role in maintaining the freshness and quality of food. Vacuum drying helps in preserving these enzymes, which are often destroyed in high-heat drying methods. Retained enzyme activity can improve the flavor profile and nutritional value of the dried product.

Better Flavor and Color

The gentle nature of vacuum drying helps in preserving the natural flavor and color of fruits and vegetables. Because the drying process occurs at lower temperatures, the compounds responsible for flavor and color remain intact. This makes vacuum-dried products more appealing to consumers who seek high-quality dried fruits and vegetables.

Flavor Compound Retention

Flavor compounds are volatile and can easily be lost during high-temperature processing. Vacuum drying preserves these compounds, ensuring that the dried products have a rich and authentic taste. This is particularly important for products like herbs and spices, where flavor is a key selling point.

Color Preservation

The visual appeal of food is critical for consumer acceptance. Vacuum drying helps retain the vibrant colors of fruits and vegetables by preventing the Maillard reaction and other browning processes. This ensures that the dried products are not only nutritious but also visually appealing.

Texture Maintenance

Vacuum drying assists in maintaining the texture of fruits and vegetables, preventing them from becoming too brittle or tough. This makes rehydration easier and more effective, allowing the products to mimic their fresh counterparts when used in cooking closely.

Longer Shelf Life

Vacuum drying effectively removes moisture, which is a primary factor in food spoilage. By significantly reducing the water content, vacuum-dried fruits and vegetables have a longer shelf life. This makes them an excellent option for long-term storage and reduces food waste.

Prevention of Microbial Growth

Microorganisms, such as bacteria and molds, require moisture to thrive. Vacuum drying removes this moisture, significantly lowering the risk of microbial contamination. This contributes to the extended shelf life of the products, ensuring they remain safe for consumption over longer periods.

Oxidative Stability

By removing moisture and preventing exposure to oxygen, vacuum drying enhances the oxidative stability of foods. This means that fats and oils within the fruits and vegetables are less likely to go rancid, preserving the quality and taste of the product.

Storage Convenience

The reduced weight and volume of vacuum-dried products make them easier to store and transport. This is particularly beneficial for businesses involved in the export of dried fruits and vegetables, as it reduces shipping costs and logistical challenges.

Efficient Energy Use

Compared to other drying methods, vacuum drying can be more energy-efficient. The lower temperatures and reduced drying times mean that less energy is required to achieve the same level of dehydration. This not only makes vacuum drying more environmentally friendly but also cost-effective for producers.

Reduced Carbon Footprint

The energy efficiency of vacuum drying contributes to a lower carbon footprint, aligning with the growing demand for environmentally sustainable food production methods. Producers can market their products as eco-friendly, appealing to environmentally conscious consumers.

Cost Savings in Production

While the initial investment in vacuum drying equipment can be high, the operational cost savings can be significant. Reduced energy consumption translates into lower utility bills, allowing producers to achieve a quicker return on investment.

Minimal Environmental Impact

By using less energy and reducing food waste through extended shelf life, vacuum drying minimizes the environmental impact of food production. This aligns with global efforts to create more sustainable food systems, benefiting both producers and consumers.

Applications of Vacuum Drying

Vacuum drying is versatile and can be used for a wide range of fruits and vegetables. Some common applications include:

Fruits

- Apples

- Bananas

- Strawberries

- Pineapples

These fruits benefit from vacuum drying as they help preserve their taste and nutritional value, making them ideal for snacks and other food products.

Versatility in Fruit Processing

Vacuum drying allows for the processing of various fruits, each with unique properties. Apples, for instance, retain their crispness, while bananas maintain their sweetness and aroma. This versatility makes vacuum drying suitable for diverse product lines, catering to different consumer preferences.

Snack Industry Integration

The snack industry has seen a surge in demand for healthy, convenient options. Vacuum-dried fruits provide a solution, offering consumers nutritious and delicious snacks. Their long shelf life and portability make them a staple in the healthy snack aisle.

Culinary Uses

Vacuum-dried fruits are not only great as snacks but also as ingredients in culinary applications. They can be used in baking, cooking, and even in gourmet dishes, providing chefs with the opportunity to incorporate intense flavors and nutrition into their creations.

Vegetables

- Carrots

- Peas

- Broccoli

- Tomatoes

Vegetables dried using vacuum methods can be rehydrated quickly and maintain their texture and flavor, making them suitable for soups, stews, and other dishes.

Nutrition-Packed Ingredients

Vacuum-dried vegetables serve as nutrition-packed ingredients for various food products. They are especially popular in ready-to-eat meals and instant food products, where quick preparation is necessary. Consumers benefit from meals that are both convenient and nutritious.

Rehydration Efficiency

The rehydration capacity of vacuum-dried vegetables is remarkable. They quickly absorb water, regaining their original texture and taste. This property is crucial for products like soups and sauces, where texture and flavor are paramount.

Industrial Applications

Beyond household use, vacuum-dried vegetables have industrial applications. They are used in the production of flavorings, seasonings, and other food additives, showcasing their versatility in the food processing industry.

Vacuum Tray Dryers

A vacuum tray dryer is an essential piece of equipment in the vacuum drying process. It consists of a chamber where the food is placed on trays and a vacuum pump that removes air to create a low-pressure environment. Heat is gently applied, allowing moisture to evaporate without compromising the quality of the food.

Advantages of Using Vacuum Tray Dryers

- Uniform Drying: The design of vacuum tray dryers ensures that heat is evenly distributed, resulting in uniform drying of all pieces.

- Scalability: Vacuum tray dryers can be used for both small-scale and large-scale operations, making them adaptable to different production needs.

- Ease of Use: These dryers are user-friendly and require minimal training to operate effectively.

Precision and Control

The ability to control temperature and pressure precisely is a key advantage of vacuum tray dryers. This precision ensures optimal drying conditions for various fruits and vegetables, safeguarding their quality. Producers can customize settings for different products, ensuring the best possible outcome.

Adaptability to Diverse Applications

Vacuum tray dryers are adaptable and capable of handling a wide range of products. Whether drying small batches of herbs or large quantities of fruit slices, these dryers offer the flexibility needed in diverse production environments. Their ability to handle different product sizes and volumes makes them a versatile choice for producers.

Simplified Maintenance

Modern vacuum tray dryers are designed with maintenance in mind. They feature easy-to-clean surfaces and accessible components, reducing downtime and ensuring continuous operation. Regular maintenance is straightforward, allowing producers to focus on production rather than equipment issues.

Challenges in Vacuum Drying

Despite its numerous benefits, vacuum drying does come with some challenges:

Initial Cost

The equipment needed for vacuum drying, such as vacuum tray dryers, can be expensive. This initial investment may be a barrier for small businesses or those new to food processing.

Financial Investment Considerations

For new entrants in the food processing industry, the financial investment required for vacuum drying equipment can be daunting. However, understanding the long-term benefits and potential return on investment is crucial. Businesses must weigh the upfront costs against the operational savings and product quality improvements.

Access to Financing

Securing financing for vacuum-drying equipment can be challenging. Small businesses may need to explore various funding options, such as loans or grants, to make this technology accessible. Collaborating with financial institutions that understand the industry can facilitate this process.

Market Competitiveness

The high initial cost can create a competitive barrier, with only established players able to afford the technology. However, as the demand for high-quality dried products grows, smaller businesses may find niche markets or collaborations that justify the investment.

Maintenance and Operation

Regular maintenance is crucial to ensure that the equipment operates efficiently. Additionally, operators need to be trained to handle the machinery safely and effectively.

Training and Skill Development

Proper training for operators is essential for efficient vacuum drying operations. Businesses need to invest in training programs that equip staff with the necessary skills to operate and maintain the equipment. This investment in human resources can enhance productivity and reduce operational errors.

Routine Maintenance Protocols

Establishing routine maintenance protocols is vital to prevent equipment breakdowns. Regular inspections and servicing ensure that the machinery functions optimally, reducing downtime and extending the equipment’s lifespan. A proactive maintenance approach can prevent costly repairs and production delays.

Safety Considerations

Operating vacuum-drying equipment safely is paramount. Businesses must implement safety protocols and provide ongoing safety training to minimize the risk of accidents. Ensuring that operators are aware of potential hazards and emergency procedures is crucial for a safe working environment.

Limited Capacity

While vacuum drying is efficient, the capacity of vacuum tray dryers may be limited compared to other drying methods. This means that large batches may take longer to process, which could be a consideration for high-volume producers.

Production Planning Challenges

For high-volume producers, planning production schedules can be challenging due to capacity constraints. Businesses must strategically plan their operations to meet demand without compromising product quality. Effective planning and scheduling can help mitigate capacity limitations.

Innovation in Design

Continuous innovation in vacuum dryer design is addressing capacity constraints. Manufacturers are developing larger, more efficient models to accommodate the needs of high-volume producers. Staying informed about technological advancements can help businesses choose equipment that aligns with their production goals.

Balancing Quality and Quantity

Producers must balance the need for high-quality products with the limitations of production capacity. While vacuum drying offers superior quality, businesses may need to explore complementary drying methods for certain products or peak production periods to meet demand.

The Future of Vacuum Drying

As technology advances, vacuum drying is poised to become even more efficient and accessible. Innovations in equipment design and energy use are likely to reduce costs and improve scalability, making vacuum drying a viable option for a broader range of producers.

Technological Advancements

Ongoing research and development are driving technological advancements in vacuum drying. Innovations such as improved vacuum pumps, advanced control systems, and energy-efficient designs are enhancing the process’s effectiveness. These advancements make vacuum drying more competitive and attractive for producers.

Broader Industry Adoption

As awareness of vacuum drying’s benefits grows, more industries are expected to adopt this technology. The food industry, in particular, is witnessing increased interest in vacuum drying for its ability to produce high-quality products. This broader adoption will likely lead to further innovations and cost reductions.

Sustainability and Environmental Impact

The future of vacuum drying aligns with global sustainability goals. Its energy efficiency and reduced environmental impact make it a favorable option for eco-conscious producers. As sustainability becomes a focal point in the food industry, vacuum drying is poised to play a pivotal role in creating more sustainable food systems.

In conclusion, vacuum drying is a powerful method for preserving quality and nutritional value. Its ability to maintain flavor, color, and nutrients while extending shelf life makes it an attractive option for both consumers and producers. As the food industry continues to evolve, vacuum drying will undoubtedly play a significant role in how we preserve and enjoy our fruits and vegetables.

In the quest to preserve food for longer periods, vacuum drying has emerged as a popular and effective method. This technique not only maintains the quality and nutritional value of food but also extends its shelf life significantly. In this article, we will explore the benefits of vacuum drying for food preservation, how it works, and why it is a superior choice for storing food.

Vacuum drying is a food preservation process that involves removing moisture from food under low pressure. This technique reduces the boiling point of water, allowing it to evaporate at lower temperatures compared to traditional drying methods. As a result, the food retains more of its original taste, texture, and nutrients.

How Does Vacuum Drying Work?

In vacuum drying, food is placed in a drying chamber where a vacuum pump removes air and lowers the pressure. This environment causes moisture to evaporate from the food without the need for high temperatures. The reduced heat exposure helps preserve the delicate flavors and nutritional content of the food.

Advantages of Vacuum Drying

Enhanced Nutritional Preservation

One of the key benefits of vacuum drying is its ability to preserve the nutritional value of food. Traditional drying methods often involve high temperatures, which can degrade vitamins and minerals. Vacuum drying, on the other hand, uses lower temperatures, which helps maintain the food’s nutrient profile.

Improved Flavor and Texture

Vacuum drying preserves the natural flavors and textures of food better than conventional drying methods. Because the process occurs at lower temperatures, there is less risk of overcooking or altering the food’s taste. As a result, vacuum-dried foods tend to taste fresher and have a more appealing texture.

Longer Shelf Life

Vacuum drying effectively reduces the moisture content of food, which inhibits the growth of bacteria, mold, and yeast. By creating an environment that is hostile to microorganisms, vacuum drying significantly extends the shelf life of food. This makes it an ideal choice for long-term food storage.

Space and Weight Efficiency

Dehydrated food takes up less space and weighs less than its hydrated counterparts. This makes vacuum-dried food a convenient option for those with limited storage space or for individuals who require lightweight food options, such as campers and hikers.

Comparing Vacuum Drying to Other Methods

Traditional Drying

Traditional drying methods rely on air and heat to remove moisture from food. While effective, these methods often result in nutrient loss and altered flavors. Vacuum drying, with its low-temperature approach, offers a superior alternative by preserving the food’s original qualities.

Freeze Drying

Freeze drying is another popular method for food preservation, but it can be more expensive and time-consuming than vacuum drying. While freeze drying is effective at maintaining food quality, vacuum drying offers a more cost-effective solution without compromising on taste or nutrition.

Vacuum Sealing

by M. X. (https://unsplash.com/@custom_project)

Vacuum sealing is a method that removes air from food packaging to extend its shelf life. While it is effective for short-term storage, vacuum drying goes a step further by removing moisture, which is critical for long-term preservation. Combining vacuum sealing with vacuum drying provides optimal results in food storage.

Applications of Vacuum Drying

Home Use

Vacuum drying is an excellent option for home food preservation. Whether you’re drying fruits, vegetables, or meats, this method allows you to enjoy seasonal produce year-round. Home vacuum drying machines have become increasingly affordable, making this technology accessible to more people.

Commercial Use

In the food industry, vacuum drying is used to produce a variety of products, from dehydrated fruits and vegetables to instant soups and snacks. The ability to maintain food quality and extend shelf life makes vacuum drying an attractive choice for food manufacturers.

Emergency Preparedness

For those interested in emergency preparedness, vacuum-dried foods are an essential component of any survival kit. Their long shelf life, nutritional retention, and lightweight nature make them ideal for stocking up in case of emergencies.

Tips for Successful Vacuum Drying

Choose the Right Equipment

Investing in a quality vacuum drying machine is crucial for achieving the best results. Look for a machine that offers adjustable temperature and pressure settings to accommodate different types of food.

Properly Prepare Food

Before drying, ensure that food is washed, peeled, and cut into uniform pieces. This helps ensure even drying and prevents spoilage.

Store Dried Food Correctly

Once your food is vacuum-dried, store it in airtight containers away from light and moisture. This helps maintain the food’s quality and extends its shelf life even further.

Conclusion

Vacuum drying is a powerful method for preserving food, offering numerous benefits over traditional drying techniques. From maintaining nutritional value to enhancing flavor and extending shelf life, vacuum drying is a versatile and efficient solution for both home and commercial use. By understanding and utilizing this technique, you can enjoy the benefits of preserved food that tastes great and lasts longer.