Inhaltsverzeichnis

Produktdetail

Grundprinzip: Die Hochgeschwindigkeits-Zentrifugenzerstäubung für Extrakte der traditionellen chinesischen Medizin ist eine Anwendung der Zentrifugenzerstäubungstechnik. Dabei wird auch ein Hochgeschwindigkeitszerstäuber verwendet, um flüssiges Material in neblige Tröpfchen zu verwandeln, die dann vollständig mit heißer Luft in Kontakt kommen, um die sofortige Trocknung abzuschließen und das endgültige Pulverprodukt zu erhalten.

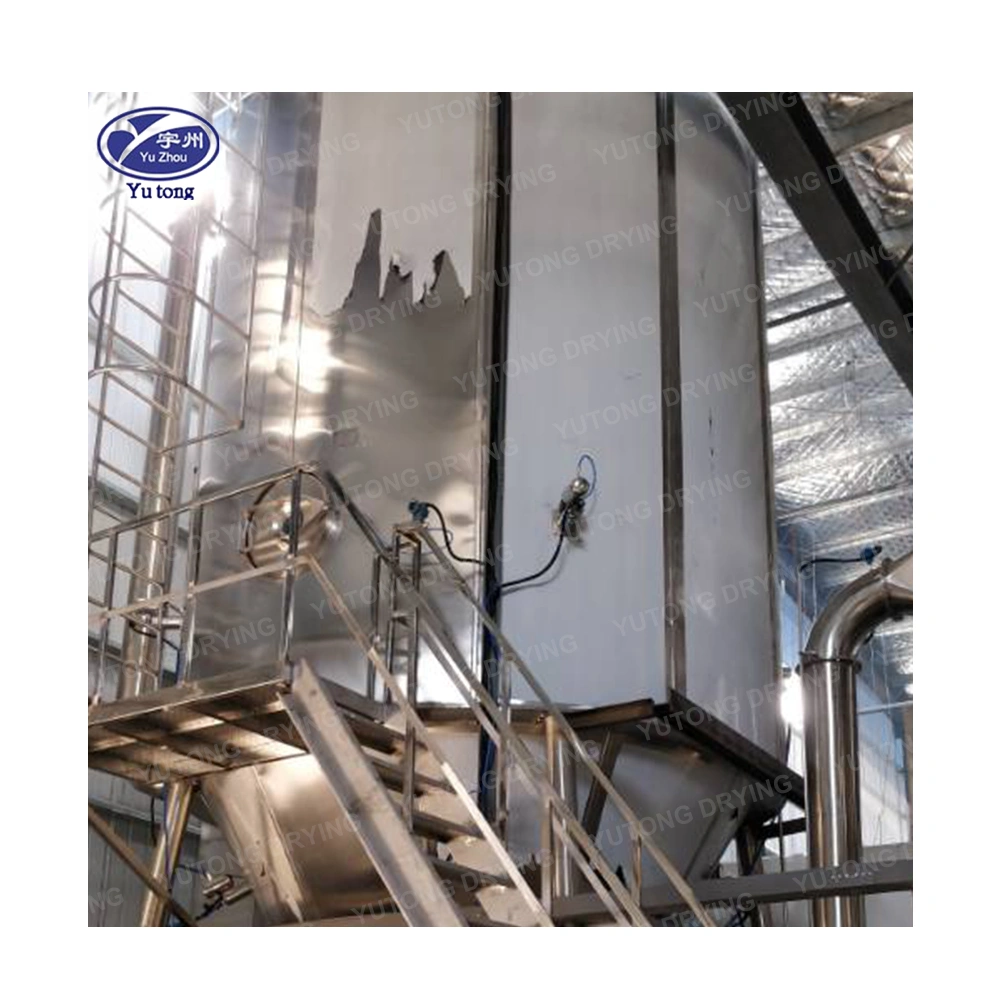

Hauptmerkmale1) Der Turmkörper ist mit einem Kühlluftmantel ausgestattet, um die Temperatur im Turminneren zu senken und das Vorheizen und Erweichen des Produkts zu verhindern

2) Der Zerstäuber oben auf dem Turm ist mit einer Kühlvorrichtung ausgestattet, um die Zerstäubertemperatur zu senken und gleichzeitig den Materialrückfluss nach oben im Wirbelstrom effektiv zu verhindern und das Phänomen der Vorwärmverkokung zu vermeiden. 3) Turmkörper und Rohrleitung sind mit einer manuellen, schnell zu öffnenden Reinigungsöffnung und einer Abflussöffnung ausgestattet. Bei Bedarf kann auch eine automatische ClP-Reinigungsvorrichtung eingebaut werden.

4) Ein automatischer Kontrolltank mit konstanter Temperatur kann ausgestattet werden

5) Manuelle Hochdruckreinigungswerkzeuge können als Zubehör zusammen mit einem Sprühtrockner angeboten werden. 6) Alle produktberührenden Teile sind aus Edelstahl (oder ganze Teile aus Edelstahl). 7) Die Produktsammelmethode verwendet zweistufige Zyklone und einen Wasserfilm-Staubwedel.

8) Die Lufteinlasstemperatur wird automatisch und kontinuierlich geregelt und ist mit der Zufuhr gekoppelt. 9) Bei einigen Produkten ist eine Luftreinigungsvorrichtung optional erhältlich.

The Essence of Industrial Spray Dryers

Industrial spray dryers serve a critical role in various industries, transforming liquid substances into dry powder form. This process is vital for creating products with longer shelf lives, consistent quality, and enhanced performance. Among these dryers, the LPG spray dryer is renowned for its high-speed operation and safety features.

Understanding the LPG Spray Dryer

The LPG spray dryer is a state-of-the-art machine designed for efficiency and reliability. Equipped with cutting-edge technology, it facilitates the rapid drying of liquid materials by spraying them into a hot air chamber, where they instantly transform into fine powders. This quick drying process ensures that the end product retains its essential properties and quality.

Key Features of the LPG Model Aluminium Sulfate Spray Dryer

Key Features of the LPG Model Aluminium Sulfate Spray Dryer

The LPG model aluminium sulfate spray dryer is engineered to meet the demands of industrial applications, offering a range of features that set it apart:

- High Speed: This model operates at exceptional speeds, significantly reducing drying times and increasing production efficiency.

- High Safety: Safety is a top priority, with the machine incorporating advanced safety mechanisms to protect both the equipment and operators.

- CE Certification: The LPG model meets rigorous European standards, ensuring it adheres to high-quality and safety benchmarks.

Advantages of Using an LPG Model Spray Dryer

Effizienz und Leistung

The LPG model spray dryer is designed for optimal performance. Its high-speed operation means more material can be processed in less time, leading to increased productivity. This efficiency is crucial for industries that require large-scale production of aluminium sulfate and other materials.

Safety First

Safety is an integral aspect of the LPG spray dryer. The design includes multiple safety features that protect against overheating, pressure build-up, and other potential hazards. This ensures a safe working environment and reduces the risk of accidents, providing peace of mind to operators and supervisors alike.

Quality Assurance

By utilizing the LPG spray dryer, businesses can guarantee the quality of their end products. The precision drying process ensures uniform particle size and moisture content, resulting in consistent and high-quality powders. This consistency is vital for maintaining product standards and meeting customer expectations.

Applications in Aluminium Sulfate Production

Aluminium sulfate is a versatile compound used in a variety of applications, including water treatment, paper manufacturing, and dye production. The LPG model aluminium sulfate spray dryer is specifically designed to meet the demands of aluminium sulfate production, providing reliable and efficient drying solutions.

Water Treatment

In water treatment facilities, aluminium sulfate is used as a coagulant to remove impurities and clarify water. The LPG spray dryer’s ability to produce high-quality aluminium sulfate powder ensures effective water treatment processes, contributing to cleaner and safer water supplies.

Paper Manufacturing

In the paper industry, aluminium sulfate is used to improve paper quality and strength. The consistent particle size and moisture content produced by the LPG spray dryer ensure that paper manufacturers receive a reliable product that enhances their production processes.

Dye Production

Aluminium sulfate is also used in the production of dyes and pigments. The LPG spray dryer’s precision drying process ensures that the aluminium sulfate powder meets the stringent requirements of dye manufacturers, providing a reliable and high-quality base for their products.

Auswahl des richtigen Sprühtrockners

When selecting a spray dryer for industrial applications, it’s essential to consider several factors to ensure you choose the best equipment for your needs:

Capacity and Speed

Consider the volume of material you need to process and the speed at which you need to produce it. The LPG model’s high-speed operation makes it ideal for large-scale production.

Sicherheitsfunktionen

Ensure the spray dryer includes comprehensive safety features to protect both operators and equipment. The LPG model’s advanced safety mechanisms make it a reliable choice.

Quality Standards

Look for equipment that meets international quality standards, such as CE certification. This ensures the spray dryer is built to high-quality specifications and adheres to rigorous safety and performance standards.

Abschluss

The LPG model high-speed high-safety centrifugal aluminium sulfate spray dryer is a powerful tool for industries requiring efficient and reliable drying solutions. Its advanced features, including high-speed operation, enhanced safety measures, and CE certification, make it a standout choice for aluminium sulfate production and other industrial applications. By investing in this cutting-edge technology, businesses can ensure consistent product quality, increased productivity, and a safer working environment. Embrace the future of industrial drying with the LPG model spray dryer and elevate your production processes to new heights.

Technische Daten

|

Spezifikation

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

|

Verdampfungsleistung (kg/h)

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

|

Prozessmenge der Materialflüssigkeit (kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

Ausstoß des fertigen Produkts (kg/h)

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

|

Feststoffgehalt der Materialflüssigkeit (%)

|

18-30

|

|||||||

|

Feuchtigkeitsgehalt des fertigen Produkts (%)

|

3-5

|

|||||||

|

elektrische Leistung (kW)

|

63

|

132

|

153

|

204

|

246

|

330

|

||

|

Wärmequelle

|

Dampf-Pius-Strom

|

|||||||

|

Sammelmethode des Produkts und seine Effizienz

|

Zyklon-Nassentstauber der Klasse eins, zwei oder drei ist größer oder gleich 95%

|

|||||||

|

automatische Kontrollmessgeräte und -instrumente

|

Anzeige der Nichtluft- und Ablufttemperatur

|

|||||||

|

Temperatur des Lufteinlasses (℃)

|

160-220

|

|||||||

|

Temperatur des Luftauslasses (℃)

|

80-100

|

|||||||

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

|

Gesamtabmessungen (mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

|

Anwendungen

Anwendbare Branchen: Baustoffläden, Produktionsanlagen, Maschinenreparaturwerkstätten, Lebensmittel- und Getränkefabriken, Bauernhöfe, Restaurants, Einzelhandel, Lebensmittel- und Getränkeläden

Key Features of the LPG Model Aluminium Sulfate Spray Dryer

Key Features of the LPG Model Aluminium Sulfate Spray Dryer