Vacuum dryers are widely used in various industries for drying different materials. They offer several advantages but also come with some limitations. In this article, we will explore the advantages and disadvantages of vacuum dryers.

Drying is an essential process in many industries, as it helps to remove moisture from materials, increase their shelf life, and improve their quality. Vacuum dryers use a combination of reduced pressure and heat to achieve efficient drying. They are particularly useful for drying heat-sensitive materials that may be damaged by high temperatures or oxidation.

Advantages of Vacuum Dryers

1. Gentle Drying Process

One of the main advantages of vacuum dryers is their gentle drying process. By operating at reduced pressure, the boiling point of water and other solvents is lowered. This allows for drying at lower temperatures, which is beneficial for heat-sensitive materials.

Materials such as pharmaceuticals, food products, and biological samples can be dried without being exposed to high temperatures that could degrade their quality or cause chemical reactions.

2. Enhanced Drying Efficiency

Vacuum dryers offer enhanced drying efficiency compared to traditional drying methods. The reduced pressure inside the dryer accelerates the evaporation of moisture, allowing for faster drying times.

This is especially useful for materials with high moisture content or those that require thorough drying. The efficient drying process can also lead to energy savings, as less heat is required to achieve the desired drying results.

3. Improved Product Quality

Vacuum drying can result in improved product quality. The low-temperature drying process helps to preserve the integrity of the material being dried, reducing the risk of degradation or damage.

For example, in the pharmaceutical industry, vacuum drying can help maintain the potency and stability of drugs. In the food industry, it can preserve the flavor, color, and nutritional value of food products.

4. Reduced Oxidation and Degradation

Vacuum dryers create an oxygen-deprived environment, which reduces the risk of oxidation and degradation of the dried material. This is particularly important for materials that are sensitive to air and moisture.

By minimizing oxidation, vacuum drying can extend the shelf life of the product and improve its storage stability.

5. Versatility

Vacuum dryers are highly versatile and can be used to dry a wide range of materials. They can handle both solid and liquid materials, as well as materials with different particle sizes and shapes.

The drying parameters can be adjusted to meet the specific requirements of each material, making vacuum dryers suitable for a variety of applications in different industries.

Disadvantages of Vacuum Dryers

1. High Initial Cost

One of the major disadvantages of vacuum dryers is their high initial cost. The equipment required for vacuum drying is complex and expensive, including the dryer itself, vacuum pumps, and control systems.

This can be a significant investment for small businesses or startups, making it less accessible compared to other drying methods.

2. Maintenance and Operation Costs

Vacuum dryers also have relatively high maintenance and operation costs. The vacuum pumps require regular maintenance and may need to be replaced over time. Additionally, the energy consumption of vacuum dryers can be significant, especially if they are operated continuously.

These costs can add up and impact the overall profitability of using vacuum dryers, especially for applications with large volumes of material to be dried.

3. Limited Capacity

Vacuum dryers often have limited capacity compared to some other drying methods. The size and design of the dryer may restrict the amount of material that can be dried at one time.

For large-scale production or applications with high throughput requirements, multiple vacuum dryers may be needed, which further increases the cost and complexity of the drying process.

4. Complex Operation

Operating a vacuum dryer requires a certain level of technical expertise. The process involves controlling the pressure, temperature, and drying time accurately to achieve optimal drying results.

This complexity can make it more challenging for operators who are not familiar with vacuum drying technology. Training and experience are often required to ensure proper operation and maintenance of the equipment.

5. Potential for Vacuum Leaks

Vacuum dryers rely on a tight vacuum seal to maintain the reduced pressure inside the dryer. However, there is always a risk of vacuum leaks, which can disrupt the drying process and affect the quality of the dried product.

Detecting and repairing vacuum leaks can be time-consuming and may require specialized equipment and expertise.

Vacuum dryers offer several advantages, including a gentle drying process, enhanced drying efficiency, improved product quality, reduced oxidation and degradation, and versatility. However, they also have some disadvantages, such as high initial cost, maintenance and operation costs, limited capacity, complex operation, and the potential for vacuum leaks. When considering using a vacuum dryer, it is important to weigh these advantages and disadvantages against the specific requirements of the drying application. In some cases, the benefits of vacuum drying may outweigh the costs, while in others, alternative drying methods may be more suitable. Ultimately, the choice of drying method depends on factors such as the type of material to be dried, production volume, budget, and quality requirements.

Benefits of Using a Vacuum Rotary Dryer

In the world of industrial drying, efficiency and precision are paramount. The vacuum rotary dryer emerges as a pivotal solution, offering remarkable advantages over traditional drying methods. This technology is critical for industries that require meticulous moisture control and temperature-sensitive drying processes. With its ability to maintain product quality while enhancing drying efficiency, the vacuum rotary dryer is increasingly becoming the preferred choice for a wide range of industrial applications. Let’s delve deeper into the benefits of using a vacuum rotary dryer and explore why it could be the perfect choice for your industrial drying needs.

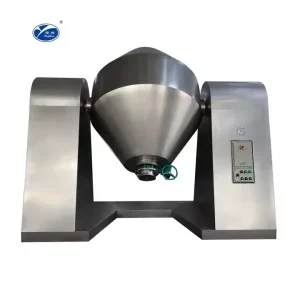

What is a Vacuum Rotary Dryer?

A vacuum rotary dryer is a sophisticated piece of equipment designed to remove moisture from materials under vacuum conditions. This drying method is particularly effective for heat-sensitive materials or those that might degrade under higher temperatures. The technology leverages the principles of vacuum to lower the boiling point of moisture, allowing it to evaporate at reduced temperatures. This capability is especially beneficial for preserving the quality and efficacy of temperature-sensitive materials.

How Does a Vacuum Rotary Dryer Work?

In a vacuum rotary dryer, the material to be dried is placed in a rotating drum. As the drum rotates, it gently agitates the material, ensuring even exposure to the heat source. The vacuum pump reduces the pressure inside the drum, decreasing the boiling point of water and facilitating quicker drying at lower temperatures. This process not only prevents thermal degradation but also enhances the consistency of the drying process. Furthermore, the continuous rotation ensures that all parts of the material are evenly exposed to the heat, preventing hotspots and ensuring uniform drying.

Advantages of Vacuum Drying

The vacuum drying process offers several benefits that make it an attractive option for industrial applications:

1. Energy Efficiency

Vacuum dryers are renowned for their energy efficiency. By reducing the boiling point of moisture, they require less energy to achieve evaporation compared to traditional drying methods. This energy-saving feature is a significant benefit for industries aiming to reduce operational costs. Moreover, the energy efficiency of vacuum dryers contributes to a smaller carbon footprint, aligning with sustainability goals and regulatory requirements. This advantage is particularly crucial in industries where energy consumption constitutes a major part of operational expenses.

2. Gentle on Heat-Sensitive Materials

One of the standout features of vacuum rotary dryers is their ability to dry heat-sensitive materials without causing damage. Traditional drying methods can expose materials to high temperatures, leading to degradation. In contrast, vacuum drying operates at lower temperatures, preserving the integrity and quality of the material. This gentle drying process is vital for industries such as pharmaceuticals and food processing, where maintaining the active properties and nutritional value of the product is essential. The ability to dry materials without compromising their quality opens up new possibilities for product development and innovation.

3. Faster Drying Times

The reduced pressure in a vacuum environment accelerates the drying process. This is particularly beneficial for industries that need to maximize throughput and efficiency. Faster drying times mean increased productivity and the ability to meet high demand. This efficiency gain can lead to shorter production cycles and improved inventory turnover, providing a competitive advantage in fast-paced markets. Additionally, the ability to quickly adapt production to meet fluctuating demand can significantly enhance operational flexibility.

4. Consistent and Uniform Drying

Vacuum rotary dryers ensure even and uniform drying of materials. The rotating drum promotes consistent exposure to heat, preventing uneven drying and ensuring all parts of the material are uniformly processed. This uniformity is crucial for maintaining the quality of the end product. Inconsistent drying can lead to quality control issues, affecting the reliability and reputation of the product. By ensuring uniform drying, vacuum rotary dryers help maintain high standards of product quality, supporting brand credibility and customer satisfaction.

Applications of Vacuum Rotary Dryers

Vacuum rotary dryers are versatile and can be used across various industries. Here are some common applications:

Pharmaceuticals

The pharmaceutical industry often requires precise drying conditions to ensure the integrity of sensitive compounds. Vacuum rotary dryers provide a controlled environment that preserves the chemical structure and efficacy of pharmaceutical products. This precision is critical for ensuring that medications remain effective and safe for consumption. Additionally, the ability to handle delicate active ingredients without compromising their potency is a significant advantage in pharmaceutical manufacturing.

Food Processing

In food processing, maintaining the nutritional value and flavor of products is paramount. Vacuum dryers are used to gently remove moisture without affecting the taste or quality of food products. This method is ideal for processing fruits, vegetables, and other delicate food items. By preserving the natural flavors and nutrients, vacuum drying supports the production of high-quality food products that meet consumer expectations. This capability is particularly valuable in the growing market for natural and organic foods, where product quality is a key differentiator.

Chemical Manufacturing

For chemical manufacturing, vacuum drying ensures that compounds are dried without altering their chemical structure. This is essential for maintaining the purity and effectiveness of chemical products. The ability to produce consistent and high-purity chemicals is crucial for meeting industry standards and customer specifications. Vacuum rotary dryers provide the precision and reliability needed to achieve these standards, supporting the production of high-quality chemical products.

Comparing Vacuum Drying to Other Methods

Spray Drying Disadvantages

While spray drying is another common method, it has certain drawbacks compared to vacuum drying. Spray drying requires higher temperatures, which can be detrimental to heat-sensitive materials. Additionally, the process can lead to uneven particle sizes and potential quality issues. These limitations can restrict the range of materials that can be effectively dried using spray drying, making vacuum drying a more versatile option for certain applications. Furthermore, the ability to maintain tighter control over drying conditions with vacuum drying can lead to improved product quality and consistency.

Rotary Vacuum Dryer vs. Other Vacuum Dryers

Rotary vacuum dryers have distinct advantages over other vacuum drying methods. The rotating action promotes uniform drying and reduces the risk of clumping or sticking. This makes rotary vacuum dryers particularly effective for materials that require gentle handling. The design of rotary dryers facilitates efficient heat transfer and consistent drying, leading to superior performance compared to static vacuum dryers. This efficiency is particularly beneficial for complex drying processes where uniformity and precision are critical.

Key Considerations for Choosing a Vacuum Rotary Dryer

When selecting a vacuum rotary dryer, consider the following factors to ensure you choose the right equipment for your needs:

Material Compatibility

Ensure that the dryer is suitable for the specific materials you intend to process. Consider factors such as heat sensitivity, particle size, and moisture content. Compatibility with the material is crucial for achieving optimal drying performance and product quality. Additionally, understanding the material’s properties can help in selecting the appropriate drying parameters, ensuring efficient and effective drying.

Capacity and Throughput

Evaluate the capacity of the dryer to ensure it can handle your production volume. Consider both current and future needs to accommodate potential growth. Selecting a dryer with the right capacity is essential for maintaining efficient production and avoiding bottlenecks. Additionally, considering potential future expansions can help in making a cost-effective investment that supports long-term business growth.

Energy Consumption

Assess the energy efficiency of the dryer to minimize operational costs. Look for models that offer energy-saving features and advanced control systems. Energy-efficient dryers can significantly reduce operational expenses, contributing to a more sustainable and cost-effective production process. Additionally, advanced control systems can provide greater flexibility and precision in managing the drying process, leading to improved efficiency and product quality.

Conclusion

Vacuum rotary dryers offer a host of benefits for industries that require precise and efficient drying solutions. From energy savings to gentle handling of heat-sensitive materials, this technology stands out as a versatile and effective choice. Whether you’re in pharmaceuticals, food processing, or chemical manufacturing, a vacuum rotary dryer could be the key to improving your drying processes and enhancing product quality. As you explore your options, consider how a vacuum rotary dryer could transform your operations and provide a competitive edge in your industry. Embracing this advanced drying technology can lead to improved operational efficiency, reduced costs, and superior product quality, positioning your business for success in competitive markets.